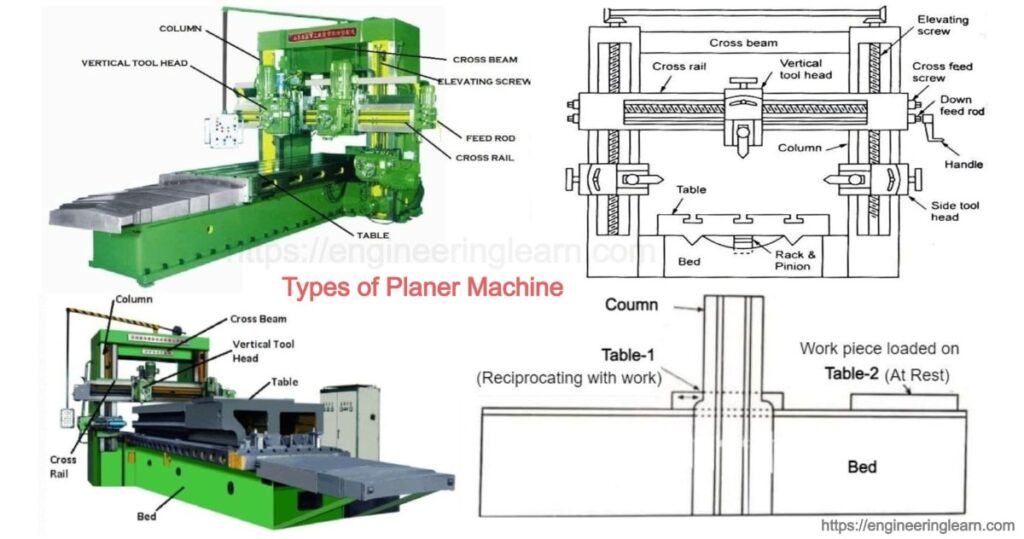

Types of Planer Machine: Parts, Applications, Working Principle, Advantages & Disadvantages

What is a Planer Machine?

Types of Planer Machine: Parts, Applications, Working Principle, Advantages & Disadvantages :- The planer machine is a machine tool which is used to produce accurate plane surface and slots. This machine looks similar to the shaper machine but there are certain dissimilarities which separates both of them. The planer machine is much bigger in size than the shaper machine and, most importantly, in shapers the tool reciprocates and work piece remains stationary, whereas, in planer, tool remains stationary and the work piece reciprocates. The tool used in planer machine is a single point cutting tool, similar to the shaper or slotter machine.

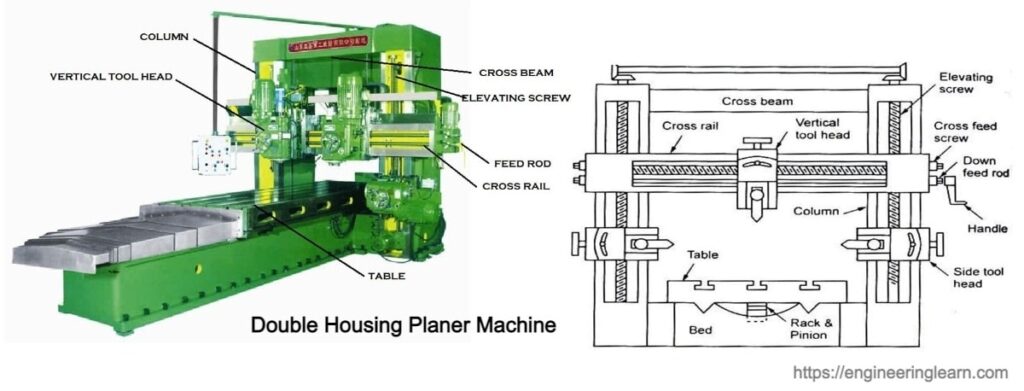

Parts of Planer Machine

The planer machines generally include following parts: –

1. Bed

It is a box like heavy structure made of cast iron. It consists of slots, generally V-slots, over its surface for the movement of table. It supports the columns and bears all the machining loads; also, it houses the movement mechanism for the table.

2. Table

The table is also a rectangular structure made of high-quality cast iron. Its main function is to support the work piece and reciprocates along with the slots of the bed. The upper surface of table is machined very fane and accurately so to avoid any kind of dimensional error in the work piece during the planning operation.

3. Column (Housing)

The column is vertical box like structure which is set perpendicular on both side of the bed. Its main function is to provide the housing for the side tool head and support the cross rail. Apart from this, it also houses the movement mechanisms for the cross rail.

4. Cross Rail

Cross rail is the horizontal structure that fits over the bed by the support of columns. The cross rail houses the vertical tool head and provides additional rigidity to the machine. It can move up or down by the help of lead screw housed in the column.

5. Tool Heads

There are generally three tool heads provided in a planer machine. The top tool head is to fit the tool for the machining of upper surface of work piece whereas the side ones are for the machining of side surface of the work piece.

Working Principle of Planer Machine

The planer machine works on the principle “The tool remains stationary while the work piece reciprocates against the tool” and “The cutting will occur only when the work piece moves in forward direction whereas the backward direction is idle”. The work piece is mounted over the work table which reciprocated over certain mechanism. The forward motion of the table is called cutting stroke whereas the backward motion is called idle stroke. The feed is provided to the tool heads by the help of lead screw mechanism.

There are basically two kinds of machining operation performed over the planer machine; vertical flat operation and horizontal flat operation. In vertical flat operation the vertical faces of the work piece are machine through the horizontal tools whereas in horizontal flat operation, the horizontal faces of the work piece are machined by the help of vertical tool head.

Types of Planer Machine

On the basis of the construction, the planer machines are categorized into following units;

1. Double Housing Planer Machine

It is a most common type of planer machine used in production processes. This machine consists of two columns (housing units) so that it can machine two opposite vertical surfaces of the work piece at the same time. The work table is generally drived by mechanical or hydraulic devices. The mechanical device works on the arrangement and motion of links whereas the hydraulic device works on the fluid pressure.

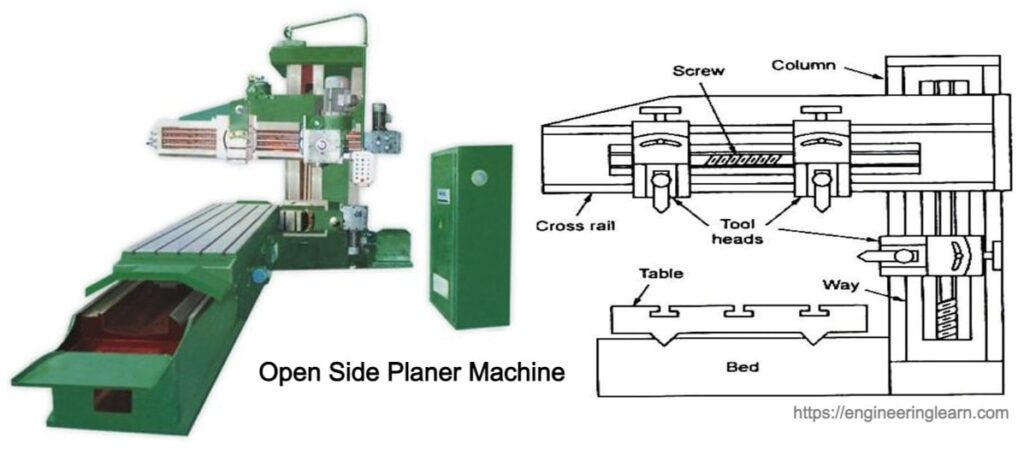

2. Open Side Planer Machine

The construction of open side planer machine is similar to the double housing planer machine except it uses single column instead of two columns. This machine is helpful in machining a wide work piece that could not be fit in to the double housing planner.

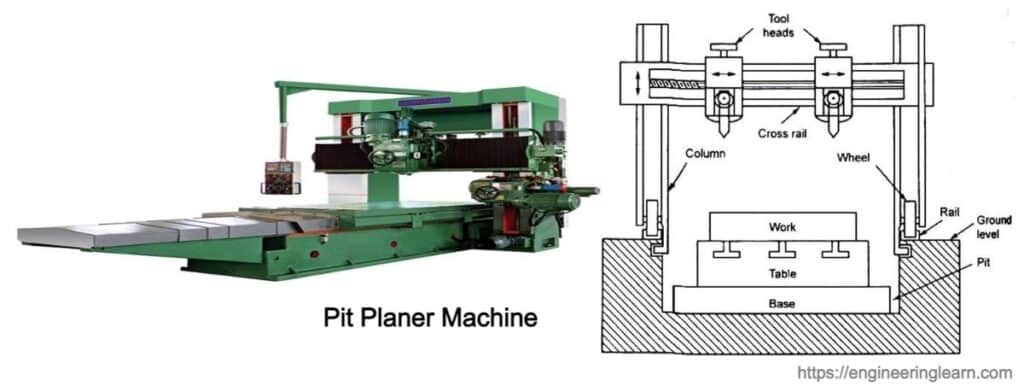

3. Pit Planer Machine

This machine has a heavy construction in which the table is kept in a pit. This planer machine works against the working principle of the planners as in this machine table is kept stationary inside the pit whereas the tool reciprocates along with columns and cross rail. The table of the planer machine is generally kept at level to the ground, so that very heavy work can be mounted over the work table with certain ease. There is no side tool head, instead two vertical head is mounted on the cross rail. Thus, only top surface can be machined by this planner at a time.

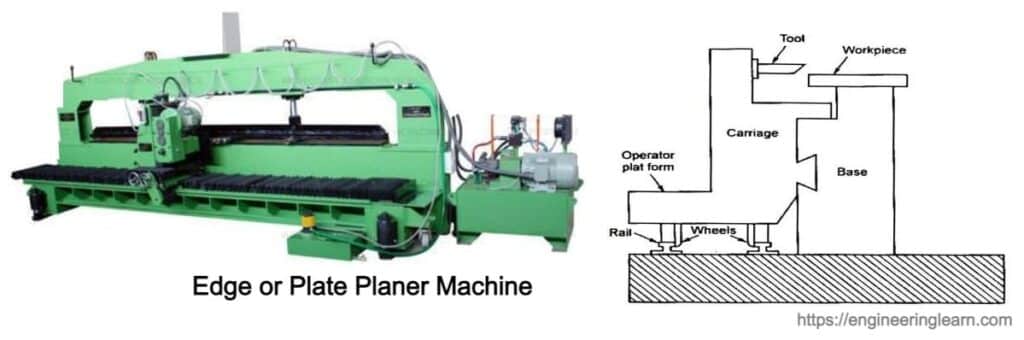

4. Edge or Plate Planer Machine

This planer machine is generally used to square or bevel the edges of the work piece. Generally, plate kind of job is machined over this planner, hence it is also known as plate planner.

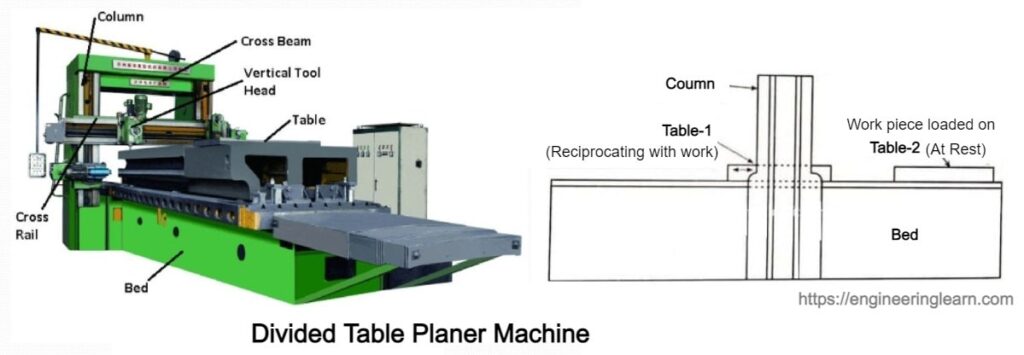

5. Divided Table Planer Machine

This kind of planer machine consists of two tables. Both the table can have the reciprocating motion; depending upon the need. This machine can save the job loading time on the work table as when one table is loaded and reciprocating, another table can be used for the loading of second job. This machine is generally used for the mass production. For heavy jobs, both the table clamped together and reciprocated while planning operation.

Applications of Planer Machines

- To generate flat surface.

- To remove heavy amount of material from the work piece at faster rate.

- To cut numbers of slots at a time.

Advantages of Planer Machines

- Better surface finish.

- Low maintenance cost.

- High accuracy.

- High material removal rate.

Disadvantages of Planer Machines

- High initial cost.

- High tool wear.

- High power consumption.

- Skilled worker required for the operation.