What is Concrete? 26 Types of Concrete, Uses, Properties, Advantages & Disadvantages [Explained]

![What is Concrete? 26 Types of Concrete, Uses, Properties, Advantages & Disadvantages [Explained]](https://engineeringlearn.com/wp-content/uploads/2022/08/Concrete-1024x539.jpg)

Introduction

What is Concrete? Types of Concrete, Uses, Properties, Advantages & Disadvantages [Explained]: – We are actually living in concrete or substantial age. It has become so significant in light of the fact that it is utilized in pretty much every kind of construction like (buildings, streets and roadways, tunnels, storage dams and power generating plants, air terminals, and nuclear power reactors).

Subsequently, in buildings, it is utilized nearly from foundations to the highest storey. In transportation, it is utilized on roads, parkways, Airports, and so on.

What is Concrete?

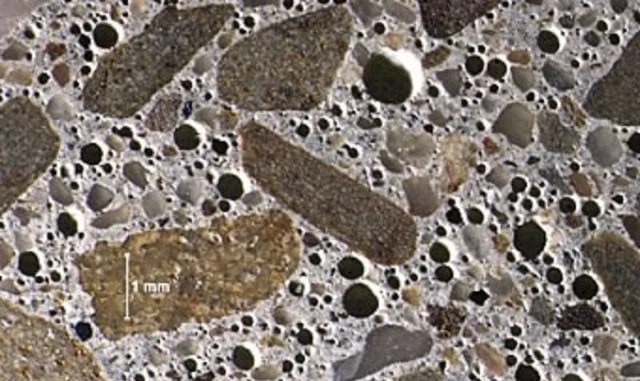

Concrete is considered as a chemically combined mass where the idle material goes about as a filler and the binding materials go about as a binder. The main important materials are cement and lime. Inert materials utilized in concrete are termed aggregates. The most common aggregates are sand, block chips, stone chips, rock, shells, and so on. It is durable, solid, and along these lines, can be utilized for long-term commercial business undertakings and underground utilities as well.

What Kind of Ingredients are Used in Concrete?

Following are the ingredients of concrete.

- Binding material (Cement or Lime).

- Fine aggregate (Sand or such other materials).

- Coarse aggregate (Gravel, Crushed stone, or such different materials). Furthermore, Water.

- Admixtures are classed as optional ingredients.

A) Function of Binding Material

The function of a Binding material (Cement or Lime) is to bind or tie the coarse and fine aggregate particles together.

B) Function of Aggregates

The Function of Fine aggregates effectively fills all the open spaces in between the coarse particles. Along these lines, the porosity of the final mass is diminished.

C) Function of Water

Water is the principal component of the concrete blend. Water plays a significant part in the process of the chemical reaction of concrete and aggregates.

D) Function of Admixtures

Admixture affects or influences the setting time of cement, and they are utilized generally for specific purposes.

Types of Concrete

1. Plain or Ordinary Concrete: ( Types of Concrete )

It is one of the most generally utilized types of concrete. In this type of concrete, the essential constituents are cement, sand and coarse aggregates designed, and blended in with a specific amount of water.

Plain concrete is for the most part utilized in the construction of asphalts and in buildings, where extremely high elasticity isn’t needed. It is additionally utilized in the construction of Dams.

2. Lightweight Concrete: ( Types of Concrete )

Any type of concrete having a thickness under 1920 Kg/m3 is classed as lightweight concrete.

Different types of aggregates that are utilized in the manufacturing of lightweight concrete incorporate natural materials like pumice and scoria, artificial materials like extended shales and clay, and processed materials like perlite and vermiculite. Lightweight Concretes are utilized, depending upon their composition, for safeguarding steel structures, they are likewise utilized in lengthy range span bridge decks, and even as building blocks.

3. Reinforced Concrete: ( Types of Concrete )

In this concrete type, steel in different forms is utilized as reinforcement to give extremely high tensile strength. The steel reinforcement is cast as rods, bars, lattices, and every single possible shape.

Each care is taken to ensure the maximum bond between the reinforcement and the concrete during the setting and solidifying process.

4. Precast Concrete: ( Types of Concrete )

This term alludes to various types of concrete shapes that are projected into molds either in a processing plant or at the site. However, they are not utilized in construction until they are totally set and solidified in a controlled condition

5. High-Density Concrete: ( Types of Concrete )

These types of concrete are prepared by utilizing high-density squashed rocks as coarse aggregates. Among such materials, Barytes is the most regularly utilized material, which has a specific gravity of 4.5.

They are for the most part utilized in nuclear power plants and other comparable structures since it provides assurance from all kinds of radiation.

6. Air Entrained Concrete: ( Types of Concrete )

It is an exceptionally prepared plain concrete wherein air is entrained as a large number of uniformly distributed particles. The Volume of air accordingly, entrained may range between 3-6 percent of the concrete

The air entrainment is accomplished by adding a little amount of foaming or gas-forming agents at the blending stage.

7. Pre-Stressed Concrete: ( Types of Concrete )

It is an exceptional kind of reinforced concrete where the reinforced bars are tensioned prior to being embedded in the concrete. Such tensioned wires are held firm at each end while the concrete blend is placed. The outcome is that when the concrete sets and solidifies, the entire concrete members, so the cast is placed into compression. Since pre-stressing includes the utilization of jacks and tensioning equipment, the pre-stressed concrete is likewise cast in the processing plants.

8. Rapid Hardening Concrete: ( Types of Concrete )

This kind of concrete is for the most part utilized in underwater construction and in repairing roads. Since its hardening time is extremely less, it tends to be hardened in only a couple of hours.

9. Glass Concrete: ( Types of Concrete )

At the point when the recycled glass is utilized as an aggregate in the concrete, this type of concrete is known as Glass Concrete. They give better thermal protection and furthermore have an incredibly engaging look when contrasted with other types.

10. Lime Concrete: ( Types of Concrete )

In this kind of cement or concrete, lime is used as a mixing material with the aggregates. Before the invention of cement, the most utilized concrete was lime concrete.

11. Asphalt Concrete: ( Types of Concrete )

Asphalt concrete is a blend of aggregates and asphalt. It is otherwise called Asphalt. They are vastly utilized in the expressways, air terminals, also in embankments. They can be hardened in only 60 minutes. That is the reason behind its vast utilization inroads.

12. Stamped Concrete: ( Types of Concrete )

They are ordinary concrete with certain few differences and are generally utilized for agricultural purposes. A stamp of various shapes and designs is placed on the concrete structures when they are in their plastic state to gain an appealing and engaging look design.

13. Roller Compacted Concrete: ( Types of Concrete )

This concrete is for the most part utilized as a filling material. They don’t have a superior strength value. They are lean concrete and are compacted with the assistance of heavy means, similar to rollers.

14. Permeable Concrete: ( Types of Concrete )

permeable concrete is ready in such a way that the water can be passed through it. They have around 15 to 20% voids with the goal that the water can pass into it. They are utilized in those areas where stormwater issues continue to happen.

15. Pumped Concrete: ( Types of Concrete )

Pumped concrete is utilized for high structural buildings where concrete transport other than the pump isn’t a simple task. They are made functional enough for easy movement. The pump utilized for transport purposes is produced using rigid or flexible materials to effortlessly discharge the concrete

16. Vacuum Concrete: ( Types of Concrete )

In this type, the greater amount of water is added to the concrete mix, and afterward, the combination is poured into the formwork.

The excess water is then eliminated from the concrete with the assistance of a vacuum pump. For that reason, it is called vacuum concrete. It will achieve compressive strength within the period of 10 days when contrasted with 28 days of ordinary concrete.

17. Ready Mix Concrete: ( Types of Concrete )

This concrete type is prepared in concrete plants or potentially shipped with the assistance of truck-mounted transit mixtures. Once they are reached at the site then, there could be no further treatment essential.

The plant location will be at an adjustable location with the goal that the concrete can be supplied before the setting time can be started.

18. Shotcrete: ( Types of Concrete )

Shotcrete is concrete prepared in a similar way as ordinary; however, the difference is that they are set differently. They are placed with the assistance of higher air pressure through nozzles. The advantage of this technique is that the compaction and placing of concrete will be done at the same time.

19. Fiber Reinforced Concrete: ( Types of Concrete )

The fibers might be of different materials like steel, polymer, glass, carbon, or even regular strands like coconut fiber. Fiber reinforced concrete can likewise be utilized where increased resistance to cracking is required.

Some types of fibers react with the concrete; unique consideration ought to be taken while utilizing them. It has been utilized for the most part as overlays for asphalts in bridges, air terminals, and over modern floors.

20. Self Consolidated Concrete: ( Types of Concrete )

These kinds of cement or concrete are compacted by their weight, mean by the consolidation process. There is no requirement for utilizing a vibrator or doing manual compaction. The functionality of concrete is in every case high in this type. That is the reason it is otherwise called flowing concrete.

21. High Strength Concrete: ( Types of Concrete )

High-strength concrete is concrete with a strength of more than 40 N/mm2. It is otherwise called High-performance concrete (HPC). High-performance concrete is utilized to accomplish a few unique properties in concrete like high strength, low shrinkage, self-compaction, high fire resistance, and so on.

22. Fly Ash Concrete: ( Types of Concrete )

Concrete utilizing fly ash is called fly ash concrete. Fly ash is obtained from coals. Fly ash can be utilized to replace fine aggregates or concrete or to replace to some extent both. Fly ash further improves work ability in the fresh concrete and sturdiness and strength in hardened concrete. The particles of fly ash ought to be finer than cement particles.

23. Silica Fume Concrete: ( Types of Concrete )

Silica fume is a byproduct of silica which is finely divided in the industry. Concrete in which silica fume is utilized is classified as “silica fume concrete.”

The typical concrete with a typical water-concrete proportion generally has miniature pores, which limits the strength of regular concrete. Silica fume is likewise a pozzolana which will add to the strength. Subsequently, silica fume, alongside superplasticizers is an important part of elite execution and high-strength concrete.

24. Ferro-Cement Concrete: ( Types of Concrete )

Ferro-concrete cement ought not to be mistaken for fiber concrete. Ferro cement comprises closely spaced-wire meshes which are impregnated with a rich blend of concrete mortar. The steel content of this concrete will be basically as high as 300 to 500 kg/m3 of mortar. As the material comprises of a large percentage of steel, it has high pliability and tensile strength.

25. Pre-Packed Concrete: ( Types of Concrete )

Pre-packed concrete is utilized in special circumstances, for example, where a large volume of concrete (like a large machine block establishment) has to be cemented without construction joints. However, it is likewise conceivable to pack some of the ingredients in the form-work and afterward fill the pores with exceptionally prepared concrete sand grout so it will fill all the pores and form a concrete mass.

26. Polymer Concrete: ( Types of Concrete )

Polymerization is a process of change of monomers into polymers. In normal concrete or cement, you should have notice that micropores can’t be avoided. The impregnation of monomer into these pores and ensuing polymerization is the technique that has been grown as of late to reduce the porosity of the concrete and to improve its solidarity and different properties.

Below are four types of polymer concrete materials accessible as of now

A) Polymer Impregnated Concrete (PIC)

This concrete type is customary cued concrete, which is dried in an oven, and the air in the open cells is taken out by vacuum. A low viscosity monomer is brought into these spaces, which is then polymerized by use of chemical action or intensity or by utilizing radiation.

B) Polymer Portland Cement Concrete (PPCC)

This type of concrete is made by blending a monomer alongside the blending of aggregates, cement, and water. Nonetheless, the concrete obtained by this method isn’t as strong as the impregnated type.

C) Polymer Concrete (PC)

In this type of concrete, instead of concrete, the polymer is utilized with the aggregates. It’s anything but genuine concrete as utilized in structural designing terminology.

D) Partially-Impregnated & Surface-Coated

This name is self-explanatory. This multitude of materials at present is generally utilized in building construction just to further develop strength or repair works.

Advantages of Concrete

- Ingredients of concrete are effectively accessible in most places.

- Not at all like natural stones, concrete is free from deformities and defects.

- Concrete can be manufactured to the ideal strength with an economy.

- The durability and toughness of cement are extremely high.

- It tends to be cast to any ideal shape.

- The casting of concrete should be possible in the functioning site which makes it economical

- The maintenance or support cost of concrete is practically immaterial.

- The deterioration of concrete isn’t considerable with age.

- Concrete makes a building fire-safe because of its non-combustible nature.

- Concrete can endure high temperatures.

- Concrete is impervious to wind and water. Therefore, it is extremely helpful in storm shelters.

- As a soundproofing material cinder concrete could be utilized.

Disadvantages of Concrete

- Compared with other binding materials, the rigidity of concrete is somewhat low.

- Concrete is less pliable.

- The weight of compared is high contrasted and its solidarity.

- Concrete may contain dissolvable salts. soluble salts cause efflorescence

- It can without much of a stretch split and burst under extreme cold climate conditions and low temperatures.

- It requires constant and customary support to stay away from the risk of getting cracks.

Conclusion

Despite the fact that concrete is reasonably simple to maintain, the manufacturing, pouring, and fixing of concrete is critical to keeping a more drawn-out lifespan. When concrete is freshly prepared and blended, it tends to be effortlessly molded into any shape. It requires very little support and can be effectively sealed or revamped with the assistance of a concrete sealant. It is solid, strong, and in this manner, can be utilized for long-haul commercial projects and underground utilities too.