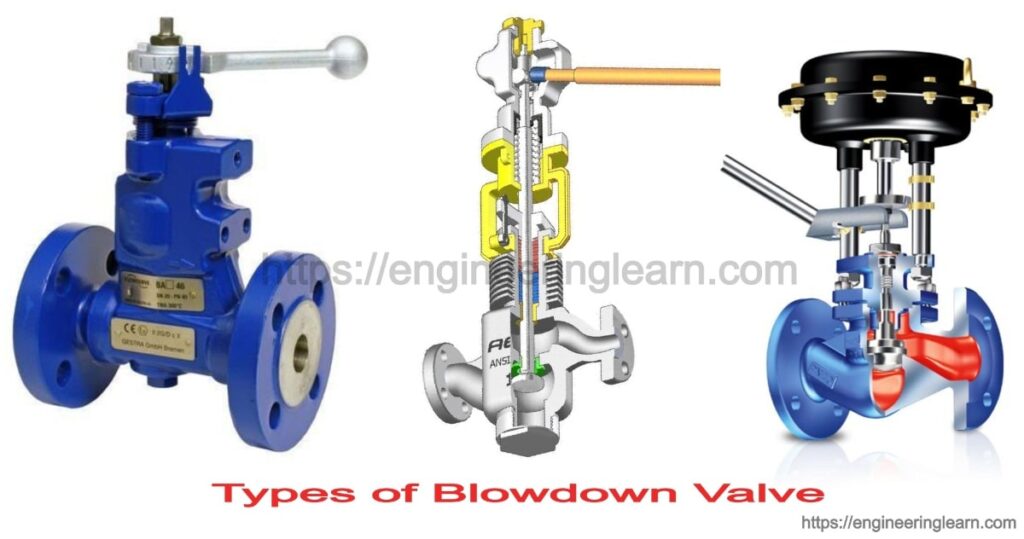

Types of Blowdown Valve: Working, Operation, Uses, Applications, Advantages & Disadvantages

What is a Blowdown Valve?

Types of Blowdown Valve: Working, Operation, Uses, Applications, Advantages & Disadvantages :- Blow down valves are among the popular type of valves which are used for various applications. The most common function of the valves is to control the continuous flow of fluid in high differential pressure. They can maintain fluid tightness. These valves are used for draining liquid of some amount from equipment.

General Description of Blowdown Valve

In steam boiler water evaporates and convert to steam, and for continuous production of steam for fulfilling the requirement frequent replenishment of boiler feed water is needed. The feedwater dissolve some impurities in it and the continue evaporation of water results in damaging to the steam production in the boiler.

If blow down is not provided then the solid impurities will reach to its saturation and starts settling down in the boiler and the concentration of solid impurities are maximum where steam is produced around heat exchange surfaces. Precipitation results in the formation of scale deposits on the heat exchange surface and they thermally insulate the surface which reduce the rate of generation of steam and cause boiler metals to reach failure temperature.

They are attached to the equipment’s in which the working fluids have solid impurities. Such type of impurities does not dissolve in fluid and finally they are deposited over the surface of equipment which results in serious problems in the equipment operation.

Operation of Blowdown Valve

Normally they are attached with the equipment in process whose working fluid is water. When water have solid impurities and some water is continuously evaporated with some mechanism like vaporization in boilers or drafting in cooling towers then it increase the accumulation of solid impurities in the water left after the evaporation. If the solid impurities accumulation increases a lot then they start depositing at the surface of equipment and they results into the blockage of the path of liquid flow and then the processes in which heat transfer is required of the operation may face difficulties in their operation.

In case of boiler operations, impurities precipitation is highest at the location where water is converted in the steam. Thus the scale formed will act as insulating layer which deviate the flow of heat through equipment. When the scaling thickness increases the rate at which steam is being generated is reduces because the rate at which heat is flowing is reducing. Metal surface may also get damaged due to temperature increase if the metal surface due to the heat accumulation.

Applications of Blowdown Valve

The primary application of the blow down valve is to control the concentration of total dissolved solids and suspended solids in boiler. Blow down of boiler is a severe application which can leads to the wearing out of conventional valves as well as rapid erosion. The blow down rate are influenced by the boiler pressure, size of blow down line and the length of blow down line between boiler and the blow down vessel.

Using blow down valve can reduce the operational cost as well as less consumption of feed water, high heating efficiency. Once this valve was set then there is no requirement for regular operator intervention.

Working of Blowdown Valve

Two number of blow down valves are used in series in which one valve is used as the sealing valve and the second valve used as blow down valve. The sealing valve is opened at the starting and is closed at last. Both the valves are opened fully and rapidly in order to prevent the erosion on disk faces and on the seat. Care is taken in order to avoid the trapping rust or scale particles in valve by opening again the valve for flushing the particles through, if there is some resistance felt at the time of closing. The bottom blow down valves are generally replaced or rebuilt when the boiler is out of service for their maintenance.

Blowdown valve close the water and steam supply valves and then it opens the drain valve. And for few seconds open the upper steam valve and blow through the steam side and then closes and then for few seconds open the lower water valve and blow through the water side and then closes. After that closes the drain valve. Open the steam valve as well as the water valve. By cut off the low water fuel stop the fuel to burner condition and then the low water fuel cut off are tested for their proper operation with the help of float in chamber which senses the reduced level of water. And then the blow down valve is opened and the burner is fired. This leads to the loss of water in boiler and also shut off fuel to the burner.

The percentage of blow down can be calculated as,

Blow down percentage = (Quantity of blow down water/ Quantity of feed water) x 100

Types of Blowdown Valve

Precipitation of solid impurities might be slower or faster depending on the basis of process condition and water quality which is being used. Based on this, there are two types of blowdown valve:

1. Surface Blowdown Valve: ( Types of Blowdown Valve )

They are used when solid impurities precipitation is are relatively slower. The simplest design of the surface blow down valve is that pipe near surface of water level inserted and the water through the valve is permitted to flow out. It let the equipment to operate continuously with steady state condition. When they are used in boilers then water flow out are sent to the flash tank in which they are flashed and flashed steam then heat up feed water.

For more efficient design a swivel joint is used and then short length pipe are suspended on float. With the help of this mechanism, it can collect the oil which is floating at the surface of water because if oil was not removed then it results in foaming inside boiler. Surface blow down generally fed heat exchanger and flash tank for the recovery of heat. These valves continuously flow off small volume of water from boiler in order to get rid of the dissolved impurities present. They are very effective in order to remove the water in which the concentration of impurities is higher and the water in which impurities are very high are found where the steam separated in the boiler.

2. Bottom Blowdown Valve: ( Types of Blowdown Valve )

In bottom blow down valve compounds are added for the treatment of water and then sludge form because of the accumulation of solid impurities and the sludge settle at bottom quickly where a mud drum is being provided for the collection of it. And then the valve is opened periodically for a very short span of time for the removal of settled sludge.

They are not operated in steady state and are not advised to open valve for long period of time because it will affect the level of water in the equipment. Level of water decreases very fast and then equipment need to be shutdown to avoid it from run dry. Therefore pipe diameter need to be enough large so that sludge do not stuck and block the flow.

Materials Used for blowdown Valve

Brass, copper, bronze, cast iron, aluminum, stainless steel, Monel, nickel, zirconium etc.

Uses of Blowdown Valve

- They are used for reducing the water cut offs.

- These valves are used with the air compressors.

- They can be used for controlling the solid concentration in the boiler.

- They are used for the removal of unwanted materials and slug after the cleaning of pipes.

Advantages of Blowdown Valve

- High productivity.

- Their maintenance is easy because their designs are simple.

- They are suitable for various steam boilers.

- Maintenance time of blow down valve is less.

- Shutdown of the valve is decreases periodically due to the deposition of precipitate.

- They can be operated manually as well as automatically easily.

- It helps in maintaining solid impurities under limited rates.

- They help in removal of impurities which accelerate corrosion.

- They prevent in scaling of internal surfaces as well as the boiler tubes.

- Prevent carryover of impurities which results in prevention of contamination of the steam.

Disadvantages of Blowdown Valve

- Heat loss because the hot water is going out of water drum.

- When the valve is open then there is huge pressure loss.

- As the blow down of boiler increases fuel consumption increases.

- When the blow down is manual then there is additional work hour require for the operation.

Image Source :- alphagroup,