Steel Fabrication: Definition, Types, Parts, Uses, Methods, Benefits & Raw Materials

Steel Fabrication Introduction:

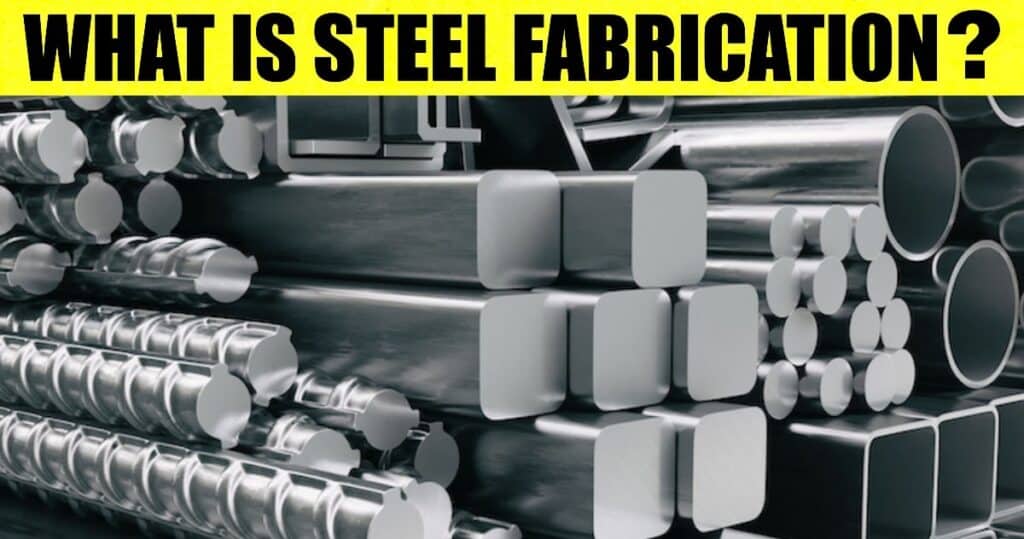

Steel Fabrication: Definition, Types, Parts, Uses, Methods, Benefits & Raw Materials: – Steel has been one of the most desired materials for some time now, and it has plenty of different machines. The noteworthy toughness and different factors are the reason why steel components are utilized in basically anything, from transportation appliances to structures or entire buildings. Steel is viewed as an alloy of iron and different metals. There are a wide variety of different kinds of steels, which are utilized in structural and fabrication operations.

What is Steel Fabrication?

Steel fabrication includes taking raw materials and molding them to their desired form. The raw materials are melted down and blended into steel prior to being constructed into the desired shape. The process requires a skilled expert who has experience in taking raw components and further transforming them into attractive things, and there is in many cases very little room for error. Industrial facilities or industries use steel fabrication to make everything from vehicular parts to home appliances.

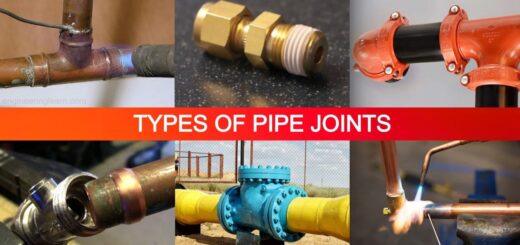

The essential techniques of fabricating include cutting or burning, shaping, machining, or welding.

Below is a Short Outline of how every one of these Strategies Works:

1. Machining

This process incorporates using a specific piece of equipment to shave away pieces of metal to make it into the essential shape. A piece of the tools that are involved are lathes, drills, etc.

2. Cutting

We use water jet cutting, a grating process that utilizes high-pressure water to cut virtually any material with an elevated degree of accuracy and no distortion.

3. Welding

This is a typical type of steel fabrication. Welding is utilized to bend or combine pieces to make them one piece. As a CT welding contractor, they have practical experience in MIG and TIG welding of Steel, Stainless Steel, and Aluminum and utilize pulsed welding machines to assist with controlling the heat put into a part, limit distortion, and improve the quality of the parts they produce.

Mechanical engineers who are entrusted with steel fabrication would at first need to check the original shape of the unrefined substance (raw material) which could exist as a flat plate, reshaped channels, pipes, or various beginning structures. At the point when the steel has been dealt with, the following stage to be taken by the fabricator includes deciding its shape. There are two factors that govern this outcome, specifically the software package and the equipment accessible in the machine shop.

What are the Basic Raw Materials Involved in Steel Fabrication?

Below are a few basic raw materials that are necessary for many metal fabrication projects:

A) Flat Metal Raw Materials

Flat metal is a sort of raw material utilized in manufacturing. Sheet metal is frequently utilized for making architectural components. Interestingly, flat plate metal makes car, truck, and plane parts. This kind of metal is pressed into flat pieces, and the thickness can fluctuate.

B) Welding-Wire

The term’ welding wire’ alludes to any kind utilized in welding. These include tungsten inert gas (TIG) welding wire, utilized while welding steel; MIG welding wire, commonly utilized for aluminum; and flux core welding wire, normally utilized for stainless steel. It may refer to a solitary, or multiple strands of wire twisted together. The welding wire overall involves copper, aluminum, steel, hardened steel, metal, nickel, titanium, tungsten, graphite, silver, gold, platinum, and palladium.

C) Sectional Metals

Sectional metals are steel and are utilized in designing and constructing projects.

D) Some of the Types Include

I-beam: a cross-sectional beam that seems to be the shape of the letter “I.”

Z-shape: A metal beam is in the form of the letter “Z.”

Hollow structural section (HSS): Hollow piping that is accessible in square, roundabout, rectangular, and curved shapes.

Rod: Rod is metal that is roundabout or square.

Bar: A flat piece of rectangular cross-segmented metal.

Parts of Steel Fabrication

Steel fabrication comprises three essential or fundamental parts, melting raw materials, mixing melted materials into steel, and forming the ideal shape using said steel. The whole cycle is fairly complicated, has next to no room for error, and requires an individual of specific abilities to appropriately operate everything. This process is broadly utilized by steel fabricators to generate a wide range of steel parts and details, for example,

- Bar joists

- Ladders

- Grating

- Skids

- Universal beams

- Pipe racks

- Platforms

- Universal column;

- Industrial equipment, and more.

Steel fabrication is a method that can be performed utilizing various techniques or approaches.

Methods of Steel Fabrication

Below are some of these methods: –

1. Cutting

There are a few unique strategies that can be utilized to cut a particular part of a metal piece.

2. Shearing

It’s one of the least complex methods up until this point, the cutting process comprises putting a piece of raw material between two parts of the die, which the higher part is called a punch. By pressing punch to a raw material piece isolating a solitary material piece into several different, more smaller pieces is fairly simple.

3. Water Jet Cutting

Water jet cutting is additionally an option in contrast to cutting torches, and yet, it offers no material distortion and can practically cut basically any material utilizing high-pressure water without the overheating issue that regular cutter torches have.

4. Cutter Torches

Cutter torches are additionally utilized ordinarily with regard to cutting large cross-segmented steel pieces. Their speed is good, yet it utilizes outrageous temperatures to play out the cut in any case, so the cutting areas are treated as heat-impacted zones. It is significant that the cooling style for every one of the parts that have been cut with this tool influences a portion of the properties that steel has, so it’s essential to remember that while choosing the cutting tool to utilize.

5. Bending

Bending is a process or course of changing the shape of a steel piece by applying a tremendous force to it, it is typically done by either hammering works or with press machines. Press brakes and additionally tube benders are utilized in the bending process to accomplish the necessary angle of the steel piece.

6. Welding

It’s a fairly common strategy of steel fabrication that utilizes the fusion interaction to one or the other consolidate or twist bits of steel or other material. The combination cycle is accomplished by warming steel parts to an outrageous degree, joining or bowing them while they’re hot, and allowing them to cool. There are a few different energy sources that can be utilized for welding as intensity sources, yet the most normally utilized ones are lasers, electric curves, and gas fires.

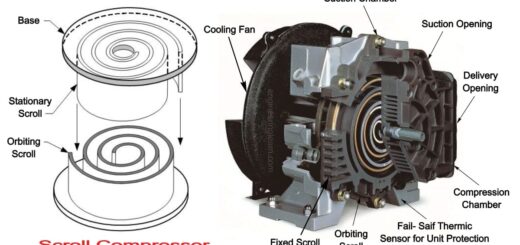

7. Machining

Machining is the process or cycle that comes from the abundance of machinery that can be utilized to shave away metal parts to form a particular shape, utilizing deviceslike drills, machines, plants, and so on.

Benefits of Steel Fabrication

Steel fabrication permits various companies to proficiently run their everyday tasks, ensuring efficiency and success in their different work processes. Other benefits of steel fabrication include:

1. It Helps Save on Time and Money

In architecture, fabricated steel is typically simpler to install. This effectiveness assists architects with saving additional time in construction. Likewise, since steel is for the most part lighter however more robust than other building substances, less material is typically required.

2. The Process Enhances the Durability of Steel

Steel is for the most part a more robust and durable metal, making it a preferred material for different purposes. That being thus, fabrication can assist with upgrading its durability since it’s coated with materials like zinc during the process, which safeguards the alloy from corrosion. Other than that, specialists likewise cover it with fire-resistant components during the said technique. This implies the end product can endure harsh conditions like precipitation and fires. Hence, a building constructed with fabricated steel is probably going to endure longer than that made of different materials.

3. It Helps in Saving the Environment

Steel is typically an environmental-friendly material as it tends to be recycled. By and large, specialists or technicians can change over old tools made utilizing this metal into different products during fabrication. This help reduces pollution and takes more time to decay on the off chance that left out as refuse in landfills.

4. This Variable assist Project Managers with Setting aside more Cash

In various industries, the cost of tools and machines made utilizing this process is for the most part lower, and these expenses frequently remain affordable for users. Other than that, since this technique makes the alloy more robust and reliable, it implies buyers enjoy a fair profit from their investment.

Conclusion

The goal of steel fabrication is to change raw or crude metal into items that can be used in constructional development, homes, and a few different places or spots. This process includes different procedures to make final products like cutting, machining, welding, and coating. For instance, fabricated steel can be used in commercial buildings, residential complexes, and temporary structures, close by warehouses in the construction sector. In the mining field, it very well may be used to make different tools and machines like loaders, pipes, fittings, and others. Then again, the energy sector can utilize it to make solar panels, gas and oil wells, electric power turbines, and a few different tools and machines.

Content Source: – cammmetals, levstal

Image Source: – roboticsandautomationnews