Pressure Gauge: Definition, Types, Uses, Parts, Applications, Advantages & Disadvantages [Complete Guide]

![Pressure Gauge: Definition, Types, Uses, Parts, Applications, Advantages & Disadvantages [Complete Guide]](https://engineeringlearn.com/wp-content/uploads/2023/02/Pressure-Gauge-1024x539.jpg)

Introduction

Pressure Gauge: Definition, Types, Uses, Parts, Applications, Advantages & Disadvantages [Complete Guide]: – Pressure Gauges are a typical measuring device used to monitor the pressure in pipelines and guarantee the safe movement of gases, liquids, and steam. The exhibitions of pumps, conveying systems, and different sorts of spray nozzles are evaluated utilizing pressure gauges.

The principal motivation behind pressure gauges is to provide information in regard to the situation with a system and prevent damage to equipment and leakages. A properly placed top-notch pressure gauge, no matter what its expense, saves money on time and expenditures.

What is a Pressure Gauge?

A pressure gauge is a technique of measuring or estimating fluid, gas, water, or intensity of steam in a pressure-powered machine giving assurance regarding leaks or pressure changes that would influence the performance of the system. Any deviation from acceptable standards can truly influence the workings of the system.

Pressure gauges have been utilized for more than 100 years and have been constantly evolving to fit the necessities of new applications. The utilization and execution of pressure gauges have made them a need as increasingly more pressure systems become functional.

Different Types of Pressure Gauges

The different varieties of pressure gauges are reliant upon where the gauge will be utilized, with various sizes, styles, and materials designed to fit specific applications. There are multiple ways pressure gauges are categorized and defined, including by use, media, and the method used to measure pressure.

The pressure is determined by the opposite force applied per unit area of a surface, an estimation not entirely determined using various methods and techniques. The right measurement of pressure is subject to the reference the pressure reading is measured against. Pressure gauges are divided into hydro-static and mechanical.

A. Hydro-static Pressure

Hydro-static pressure is created by the heaviness of a fluid above a measurement point when the fluid is at standstill. The height of the liquid influences the hydrostatic pressure. The hydro-static properties of a liquid are not constant and are influenced by liquid density and gravity.

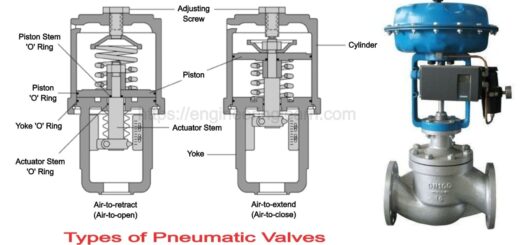

B. Mechanical Pressure

Mechanical pressure is measured or estimated by bellows, or Bourdon tube that converts fluid pressure into force.

1. Absolute Pressure Gauge: ( Types of Pressure Gauges )

Absolute pressure gauges are utilized to measure pressure independent of the natural fluctuations in atmospheric pressure. A reference vacuum is attached to the side of the measuring element, which isn’t liable to pressure; it has zero pressure with no variety. A diaphragm separates the media chamber from the vacuum chamber and distorts into the vacuum chamber as pressure rises.

2. Bourdon Tube Pressure Gauge: ( Types of Pressure Gauges )

A Bourdon tube pressure gauge has an elastic tube that is soldered or welded toward one side into a socket. An adjustment of pressure causes a deflection in the tube; this is proportional to the applied pressure and is sent to a rotary gear with a pointer. The working standard of a Bourdon pressure gauge is that a curved tube will straighten when pressure is applied; this is demonstrated by a dial or digital readout. Bourdon tube pressure gauges are utilized to measure the pressure of gas, steam, or liquids.

3. Bellows Pressure Gauge: ( Types of Pressure Gauges )

The bellows in a bellows pressure gauge are made of thin-walled springy metal connected tubes that structure a shape like an accordion; this is sealed in the free end of the gauge. As pressure is applied, it follows up on the bellows on the free end, causing it to expand and produce movement. Howls pressure measures are extremely delicate and utilized for low-strain applications.

There are two types of bellow gauges. In one form, pressure is applied to the bellows, bringing about a deformity on a counterbalancing spring. Another form utilizes the differential pressure rule with the bellows sealed between the two chambers of contrasting pressures.

4. Diaphragm Pressure Gauge: ( Types of Pressure Gauges )

A Diaphragm pressure gauge is versatile and becomes displaced when pressure is applied. This kind of pressure gauge works with a similar rule as a Bourdon pressure gauge however gauges pressure utilizing a stomach rather than an adaptable cylinder. The stomach, which is put between two spines, is utilized to decide the contrast between the applied pressure and the reference pressure. The main utilization of a diaphragm pressure gauge is for the measurement of low-level pressure.

5. Capsule Pressure Gauge: ( Types of Pressure Gauges )

A capsule pressure gauge has two thin, concentric corrugated diaphragms that are sealed firmly together around their boundaries. One of the diaphragms has a hole in the center that permits the medium to enter. At the point when pressure is applied, the diaphragms extend or contract. This adjustment of shape makes a rotary movement that shows up on the face of the gauge. Capsule pressure gauges are used for the measurement of substances and they are used exclusively for measuring the pressure of gases.

6. Digital Pressure Gauge: ( Types of Pressure Gauges )

A digital pressure gauge displays the pressure on an LCD screen and makes use of a transducer that converts the pressure value into an electrical signal. There are a wide variety of designs and styles of digital pressure gauges, with types that can be carried out for field testing and types that are installed on a pipeline.

A prerequisite of digital pressure gauges is a power source, which is regularly a battery. Analog pressure gauges work precisely without a need for a power source.

7. Differential (DP) Pressure Gauge: ( Types of Pressure Gauges )

Differential pressure gauges measure the contrast between the pressure in two chambers that are separated by an element that moves to and for as per the progressions in pressure. The movement of the element causes a movement in the pointer on the gauge face or gives a digital display reading. One of the ports of the gauge is installed on the high side, while the other is put on the low side which shows a pressure drop on the gauge. In a few cases, a linear magnetic piston is placed between the two pressure chambers that tugs at a rotary magnet connected to the gauge pointer or digital display.

8. Piezometer Pressure Gauge: ( Types of Pressure Gauges )

A piezometer is a sort of manometer that is utilized to measure the medium pressure range of liquids; it is a simple glass tube that is open at two ends. One end is connected to a pipe where the pressure of a liquid is to be measured, while the opposite end is open to the atmosphere. The tube is connected upward to such an extent that the liquid in the pipe can ascend into the tube. The pressure reading is indicated by the height of the fluid in the tube.

9. Dial or Analog Pressure Gauges: ( Types of Pressure Gauges )

The scale on a pressure gauge can be isolated into three segments with the first and third sections being the least accurate and the middle or second section being the most reliable. While choosing a simple tension check, you need the ordinary strain to reach to fall inside the center part of the dial.

10. Manometer Pressure Gauge: ( Types of Pressure Gauges )

Manometer pressure gauges measure pressure on a fluid by adjusting one section of liquid against a second segment of liquid. This sort of pressure gauge is the least difficult type and comprises a transparent tube as a “U” that is somewhat loaded up with a manometric liquid like mercury.

How Pressure Gauges Are Made?

Because there are so many types of pressure gauges, it would be impossible to describe the construction of each type. For the sake of brevity, this discussion will focus on the Bourdon pressure gauge construction.

A) Case

The cases for pressure gauges are made of plastic, steel, metal, or, most usually, stainless steel. The complexity or intricacy and kind of case are a decent indication of how costly the gauge is. Phenolic, a resin produced using phenols and aldehydes, cases are utilized in aggressive and harmful conditions like those for chemical and petrochemical production.

Cases can be filled with glycerin or silicone to prevent condensation and give security from corrosive environments that could harm the inward mechanism.

B) Socket

The socket is the initial part of the pressure gauge for the compressed liquid contacts. Reasonable gauges have a hole drilled at the power source connection, while additional costly gauges have a threaded hole for a restrictor hole. The inclusion of a restrictor hole prevents particles from entering the gauge and jamming the gauge.

C) Welding Style

One end of the Bourdon tube is welded where the linkage is appended. More affordable pressure gauges utilize stamping or a mechanical gadget to attach the linkage.

D) Pointer

The types of pointers vary according to the types of fine adjustments that the pointer permits and the pointer‘s complexity. More perplexing and refined pointers allow for changes in altitude or wear from throbs and vibrations.

E) Display

The readings on a pressure gauge can show up in a dial-style analog display or as a digital readout. As with factors, the types of displays vary depending on the type and design of the pressure gauge. A pressure gauge‘s dial scale is calibrated to the design and type of pressure gauge. In the case of the Bourdon tube, the dial is calibrated to the Bourdon tube.

F) Window

The front or face of a pressure gauge is the window that safeguards it from the environment and further protects the internal mechanism. It can be made of glass, tempered glass, or plastic. Windows made of delicate plastic flex for thermal remuneration and permit the glycerin or silicone fill to expand without bleeding. The window serves as a clear membrane that allows the user to see the dial of the gauge and read the information.

How and Where Pressure Gauges Are Used?

1. Automobiles

While examining pressure gauges for a vehicle, the principal thing that strikes a chord is the air pressure gauge for the tires. However, an air pressure gauge is significant, there are a few other pressure gauges that monitor different vehicle frameworks, for example, the cooling, oil, and engine coolant.

2. Oil Production

In the oil business, streamlines, separators, and stock tanks are under some form of pressure. Each part of an oil operation, from the wellhead to the tank, is monitored and directed by a pressure gauge. All gauges for the oil industry have safety measures built into them for the security of laborers since they can blow out when the pressure gets excessively high.

3. Food Industry

Food grade pressure gauges can endure the normal rigorous cleaning that is a fundamental part of the food preparation process. For Safety and Sanitary reasons, food processing pressure gauges should have an incredibly smooth surface with the goal that pollutants, microorganisms, and buildup can’t be caught on the outer layer of the pressure gauge.

4. Chemical Industry

Pressure gauges for the chemical industry are commonly designed to address the issues of different mediums and highly aggressive conditions. Chemical industry pressure gauges require continuous fixing and replacement. For the security of the instrument, chemical industry pressure gauges are coated in Tantalum, or Polytetrafluoroethylene (PTFE), which are particularly corrosion safe.

5. Aeronautics

There are a wide variety of instruments that inform a pilot regarding an airplane’s condition and pressure fluctuations. Pressure-sensing gadgets can be found in the flight group and engine group. They are the most critical and fundamental aspects of a plane’s activity, as they are a means of preserving its safe working.

6. Hydraulic

A hydraulic pressure gauge is a basic part of the operation of a hydraulic device. Insufficient pressure gauges can unfavorably influence the system’s performance and can be damaging to the progression of a manufacturing process. Any detectable pressure changes can indicate leaks in the system or damage to a hydraulic-driven part. Hydraulic pressure gauges must be exceptionally precise and equipped for working in harsh and perilous conditions.

Applications of a Pressure Gauge:

Below mentioned are the applications of pressure gauges as indicated by the types: –

Differential pressure gauges are utilized to monitor filtration, fluid level, and liquid flow in various ventures. They’re significant in refineries, petrochemical and chemical production lines, power plants, and clean rooms, among different places.

Gauge pressure measuring gadgets are the most widely recognized pressure measuring equipment in the industrial world, particularly in the refinery, synthetic, petrochemical, drug, food, refrigeration, cooling, and disinfection businesses.

Absolute pressure gauges are utilized to monitor adiabatic immersion pressure by meteorologists and to perform refining activities in the oil refining industry. They can likewise be utilized to gauge the vapor pressure of fluids, and vacuum reactors, actually, take a look at spillage in tanks and circuits, and measure the fall in the tension of refining vacuum segments.

Advantages of a Pressure Gauge:

The following are the advantages of pressure gauges in their various applications:

- Pressure gauges are found valuable in many applications and industries like mechanical designing, waterpower/pneumatics, and general service/test activities.

- Modern-day pressure gauges ensure gauge life span and, thus, reading accuracy.

- Digital pressure gauges are fast and exact.

- No operator interpretation is required

- There are no parallax errors in pressure gauges.

- There is back-lit capability in pressure gauges.

- Steady reading in high vibration.

- They are not difficult to re-range.

- The Bourdon tube pressure gauges give exact readings.

- The Bourdon tube is economical.

- The construction of a Bourdon tube is simple.

- They can be made to give electrical outputs by modifying them.

- In any event, for high-pressure measurements, they are safe.

- The accuracy is magnificent, especially at high pressures.

Disadvantages of a Pressure Gauges:

The following are the drawbacks of pressure gauges n their different applications.

- It is quite difficult to observe the whole scale or trends.

- They can’t read all quantities that sway.

- They require a great deal of energy with the exception of the manual types.

- They respond slowly to pressure changes.

- They are in a condition of panic.

- They are vulnerable to vibrations and shocks.

- Since the displacement of the free end of the bourdon tube is modest, enhancement is required.

- The bourdon pressure gauge isn’t reasonable for exact measurements.

- It is quite difficult to observe the whole scale or trends.

- They can’t read all quantities that sway.

- They require a great deal of energy with the exception of the manual types.

- They respond slowly to pressure changes.

- They are in a condition of panic.

- They are vulnerable to vibrations and shocks.

- Since the displacement of the free end of the bourdon tube is modest, enhancement is required.

- The Bourdon pressure gauge isn’t reasonable for exact measurements.

Conclusion

A Pressure gauge is a liquid intensity measurement gadget. Pressure gauges are required for the set-up and tuning of fluid power machines and are fundamental in troubleshooting them. Without pressure gauges, liquid power systems would be both erratic and untrustworthy. Fluid power systems would be erratic and temperamental without pressure gauges. According to an accuracy perspective, installing and right alignment of the pressure Gauge are significant perspectives.

Content Source: – iqsdirectory

Image Source: – greenishco, pyrosales, arrowfinch, precisionmass, afriso, coleparmer, differentialpressure,