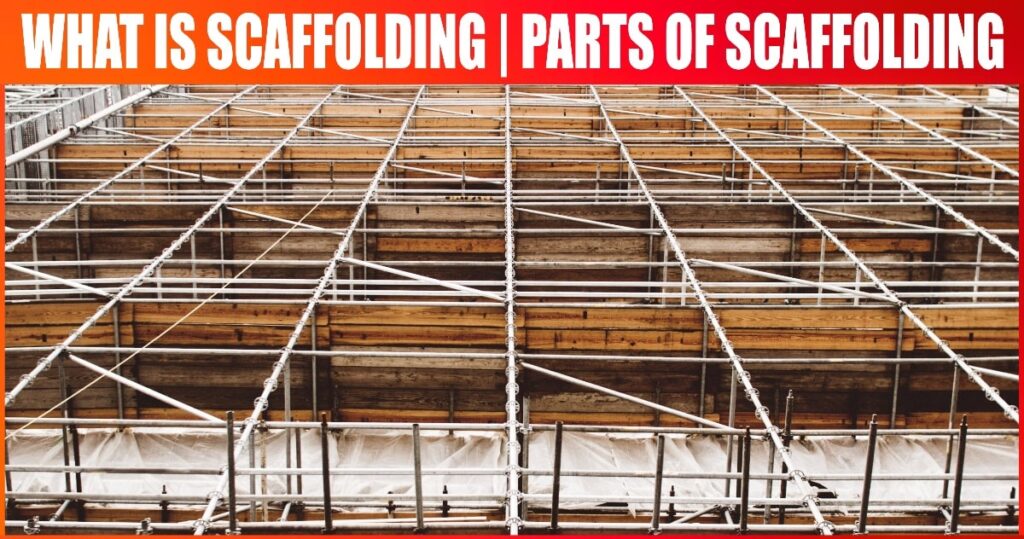

What is Scaffolding? Parts of Scaffolding, Materials, Design, Uses, Function, Risks, Precautions, Advantages & Disadvantages [Explained]

Scaffolding Introduction:

What is Scaffolding? Parts of Scaffolding, Materials, Uses, Function, Risks, Precautions, Advantages & Disadvantages: – All over the world, construction and development are for the most part unrealistic without the utilization of the right kinds of scaffolding. These temporary work platforms, set up around buildings and in structural engineering designs, allow for workers and their tools and materials to be securely transported along their multistoried levels. This, in turn, permits them to securely and efficiently complete tasks like painting, plastering, and brickwork outwardly of buildings. Numerous sorts of scaffolds are likewise utilized inside building structures, permitting workers to reach hard-to-reach spots like ceilings or electrical installations.

What is Scaffolding?

Scaffolding is built in various variations, contingent upon construction worker’s task prerequisites and the specifications of the building structure they are working on. While certain countries utilize the minimal expense option of bamboo or wooden scaffolding, large-scale construction and development projects utilize different materials, for example, steel or aluminum types. These metals offer prevalent strength and durability as well as the ability to be moved toward significant heights.

Despite the fact that aluminum is more costly than steel, it is most of the time the preferred material for many types of scaffolding since it is light and therefore simpler for workers to convey. They assemble together and dismantling of aluminum scaffolds is subsequently additionally quicker. This temporary structure fills in as a platform to support the regular class to perform its construction. As scaffolding involves work at height, it is designed following safety guidelines to decrease dangers.

Surveys show that a significant level of mishaps in construction industries are directly or by implication connected with scaffolds. In this way, the scaffolding contractors and scaffolding laborers ought to play out their obligations with extreme attention to detail. Great materials ought to be utilized for scaffolding design. Scaffolding is implicit in various varieties, contingent upon the development of laborers’ undertaking necessities and the details of the structure they are chipping away at.

While certain nations utilize the minimal expense choice of bamboo or wooden framework, huge scope development projects utilize different materials, for example, steel or aluminum types. These metals offer unrivaled strength and durability as well as the ability to be moved toward huge levels. The gathering and dismantling of aluminum platforms are accordingly likewise speedier. This fleeting design fills in as a stage to help the working people to play out its development exercises.

As scaffolding includes work at height, it is designed following wellbeing guidelines to diminish hazards. Surveys and Reviews show that a significant level of mishaps in development ventures are straightforwardly or by implication connected with scaffolding. Thus, the scaffolding worker for hire and scaffolding laborers ought to play out their obligations with extreme attention to detail. Excellent materials ought to be utilized for scaffolding design.

What is Scaffolding Design?

As scaffolding includes the safety and well being of working experts it must be designed with absolute attention to detail. The design of the scaffold ought to consider the following:

The supporting structure ought to be sufficient in strength, steadiness, and rigidity.

The safety and security of personnel-related to the erection, modification, and dismantling of the scaffold; the safety of people utilizing the scaffold; and the safety and security of people nearby the scaffold.

What are Materials Used Different Scaffolding?

Steel and Aluminum are widely used materials for scaffolding. Steel is the most preferred material for scaffolding because of its great strength and durability. Likewise, Steel as scaffolding material gives a specific measure of elasticity and flexibility to forestall cracks. Steel can uphold high loads, and workers can utilize it for transporting heavy gear and equipment as well as supplies. For tall scaffolding structures, steel material is a need from the strength requirement point that no one but steel can provide. However, Aluminum is a decent option for less demanding conditions with short heights.

Scaffolding floors are typically made of wooden boards or decking made using steel or aluminum. At the point when wooden boards are utilized as scaffolding floor material, their closures are protected by metal plates known as hoop irons or nail plates.

Uses of Scaffolding

- It is utilized to provide a platform to work with bricklayers.

- It is utilized while painting work is completed at heights.

- It is utilized during the maintenance and cleaning of tall building structures.

- Supporting the materials during the construction and development at heights is utilized.

Functions of Scaffolding

- These are needed to help or support the platform over which the workers can sit and convey the construction.

- These are likewise needed when a building needs fixing or a building ought to be demolished.

Parts of Scaffolding

The parts that makeup scaffolding vary widely based on the type of building, project requirements, and surrounding conditions of the construction. In any case, there are some major scaffolding parts that form the essential structure and design of any scaffold. Below are some points to discover seven basic scaffolding parts.

1. Base Plates & Jacks: ( Parts of Scaffolding )

Base plates, likewise referred to as sole plates, are the load-bearing base of a scaffold. They’re utilized to distribute weight and support the vertical scaffolding poles known as standards. Connecting the base plates to standards and principles ensures areas of strength for the scaffolding foundation. Base jacks are normally made from steel and are adjustable and flexible to different lengths. The adjustments are made in view of how much weight it needs to bear. They can likewise be made in different configurations and designs, for example, swivels that adjust to sloped ground.

For scaffolds that are built of different structures like steel beams, base plates can be replaced with shoring heads (U-heads, for instance).

2. Ledgers (Runners): ( Parts of Scaffolding )

Likewise referred to as runners, ledgers are tubes that run evenly along the length of the scaffold. This component is utilized to support the working platform of the scaffold. In light of its position, it determines the height at which the working boards (decks, sheets) are organized.

Ledgers are placed in the middle of each standard parallel and organized and lined up with the building’s wall. Numerous bays are associated with these ledgers both at the back and the front of the scaffold.

In some scaffolding systems, a similar part fulfills both the ledger and transom function, in which case both might be referred to as ledgers.

3. Standards (Uprights, Verticals, Legs): ( Parts of Scaffolding )

Standards, otherwise called uprights, verticals, or legs, are the long pipes or tubes that connect or interface the entire scaffold to the ground.

Standards play a part in moving or transferring the whole load of the scaffold to the ground. As mentioned above, they’re generally connected to base plates to ensure equivalent distribution of the load.

As standards are of fixed lengths, taller scaffolding requires that the pipes be connected to route the load directly through the structure. This is accomplished by utilizing the ‘pin and socket joint, which twists to lock successive pipes together.

4. Boards (Decks, Battens, Planks): ( Parts of Scaffolding )

Boards, otherwise called decks or battens, are the planks that form the working platform on a scaffold.

They’re utilized as support for workers to stand on and place their tools or instruments while working on the scaffolding. Other than providing standing help or support, boards additionally ensure worker’s safety and security when working at tall heights.

Boards are accessible in wood, aluminum, aluminum frame with plywood board, or hot-dip galvanized steel materials. Accessories like guardrails and toe boards can be added for safety and security against falls.

5. Transoms (Bearers, Putlogs): ( Parts of Scaffolding )

Transoms, or bearers, are horizontal members that meet the ledgers at right points or angles. The role of a transom relies upon the type. Fundamental transoms offer support for the standards and the working platform by standing firm on them in the situation. In the meantime, intermediate transoms give extra load-up help when placed at intervals between the fundamental transoms. Another variation is putlogs, a sort of transom with a flat end at one side, which is attached straightforwardly into the building wall to support working platforms.

The fundamental transoms are positioned right close to the standards, while the intermediate of the road transoms is connected to the middle of between the primary transoms. Both of these parts are made from one or other steel, or aluminum.

6. Couplers (Clamps, Fittings, Clips): ( Parts of Scaffolding )

Keep parts of a scaffold intact couplers, otherwise called clamps, fittings or clips. They’re not quite the same as a scaffold tie, which is utilized to connect the scaffold itself to different structures.

Couplers are chiefly used to assist with interfacing primary components of scaffolding. In any case, detailed utilization comes in a few variations – Put-log Couplers, swivel Couplers, and Right angle Couplers. Put-log Couplers are utilized to connect a ledger to a transom when the connection is needed to support the functioning board. Right angle Couplers are utilized to connect a ledger or transom to a standard, while swivel Couplers are suggested for some other point of connection between scaffold tubes, like diagonal bracing.

Couplers are generally made out of drop-forged steel or pressed steel for sturdiness and reliability. Some have a hot-dip galvanized finish to keep away from corrosion.

Couplers are utilized extensively in tube and coupler scaffolds, while system scaffolding radically diminishes the requirement for couplers through the underlying connections between nodes on the verticals and connectors on the closures of horizontal members.

7. Braces: ( Parts of Scaffolding )

Braces are diagonal tubes that reinforce or build up the scaffolds rigidity. Bracing gives strength by controlling the “unbraced length” of the platform leg Other than that, it increases the scaffold’s steadiness by ensuring the scaffold leg doesn’t fall over.

There are a few kinds of braces. Cross (transverse) braces run diagonally between ledgers and standards to expand a structure’s general unbending nature. In the meantime, façade (longitudinal) braces are attached or connected on the face of the scaffold, running corner to corner along the length of the structure at each level. They help to keep a structure from swaying. Braces are critical to hold scaffolds back from twisting and at last collapsing because of loads as well as seismic, wind, and other outer forces.

Braces are made using galvanized steel, an industry standard for heavy-duty support.

What are the Hazards and Risks of Scaffolding?

Working in scaffolding is brimming with risks. Scaffolding hazards increase with an expansion in height. Studies address that over 65% of the construction workforce necessities to work on scaffolds. Different incidents affirm the high recurrence of scaffolding hazards. The significant scaffolding hazards are mentioned below:-

- Falls from scaffolding because of improper guardrail installation.

- The breakdown of the scaffold because of improper erection.

- Falling Material from scaffolds makes the nearby district vulnerable against perils.

- Electrical hazards because of improper planning.

- Slip and fall from planks.

- Overloading platforms.

- Rolling scaffolds.

What are the Precautions to be taken for the Safety of Scaffolding?

- Scaffolds ought not to be kept in slippery or muddy or snowy spots.

- Try not to overload the scaffolds beyond their weight conveying limit.

- Feet should be kept on the decking properly and in an appropriate way.

- Try not to lean on the scaffolds to avoid from perilous movements.

- Scaffold part’s stability ought to be checked properly.

- Only inspected tagged scaffolds ought to be utilized.

What are some Safety Measures of Scaffolding?

To forestall and reduce the percentage of scaffold mishaps, here are some of the safety measures:

- Proper or legitimate workers ought to be engaged in work by wearing adequate protective Equipment.

- Scaffold should have a handhold over its foundation.

- Adjustment of leg screws of the scaffold shouldn’t surpass 12 inches. Safety belts and cords ought to be utilized at a height of 10 feet or more above the ground level.

- Plank is covered or not should be checked to keep away from the movement.

- There ought to be the utilization of a net underneath the working platform of the scaffold to catch falling objects or people.

- Wheels of scaffolds ought to be stabilized with a stone lock preventing rolling or moving of scaffolding.

Advantages of Scaffolds

- One of the significant benefits of undertaking this process incorporates its accessibility. Thus, there are lesser types of disturbances and furthermore assist with making a secure or protected working space.

- It is simpler to foster the interconnected layout and guarantees full admittance to the entire region.

- The scaffolding provides a firm balance to the laborers.

- It helps laborers with adjusting themselves to different positions. It can in like manner assist with unequivocal capabilities and explicit tasks.

- One of the significant benefits of scaffolding is the means by which it can contribute to expanding efficiency.

- It increases the productivity of the workers and makes the process secure and safe.

- Since construction is a genuinely demanding task, this can assist with making a better workspace.

- The structure of assembling and dismantling the scaffolds is basic and simple. Hence, this saves a great deal of time and makes the process faster.

- It takes a minimal amount to be set up and taken down. Make a point to think about this as your primary option for scaffolding.

- The most crucial benefit of this process is the long-lasting structure.

- It likewise offers the number of bridging points, hence lessening the distance the workers need to cover. This saves both time and energy for your workers. Since it is long-lasting and durable, it likewise ensures the process is safe and secure from any potential harm.

Disadvantages of Scaffolds

- It is fundamental to be aware about the load as leaving materials on the scaffold can have a dangerous or risky outcome. It can fall off because of the overload.

- It is crucial to look at the quality of the scaffold you are purchasing prior to utilizing it.

- Ensure you don’t utilize scaffolds that are damaged and tempered. Do counsel experts to repair it or purchase a new one.

- One needs to follow or adhere to the guidelines it ought to be completely accurate.

- The workers must be trained around scaffolding appropriately prior to utilizing them.

- By shortening the construction time, it maximizes productivity and limits the risks.

Conclusion

Scaffolding is a kind of impermanent construction and development that is utilized for access around the building structure when the height of the building structure surpasses around 1.5 m. Scaffolding enables the construction or maintenance crew to work on the building without setting foot in it. Besides, one more vital role of these scaffolds is that they make it feasible for various specialists to work next to each other all the while, in this way speeding up the construction and development process and thus, keeping costs, however much as could reasonably be expected, to a minimum. They ought to be sufficiently strong enough to hold workmen and different materials placed on it. Setting up scaffolding platforms is easy and not so time-consuming, considering the absolute flexibility they render and the convenience to complete risky undertakings with ease.

Content Source: – avontus, dreamcivil, civilconcept, stakscaffold

Image Source: – pexels