Jacketed Valves: Definition, Types, Construction, Materials & Advantages

Description of Jacketed Valves

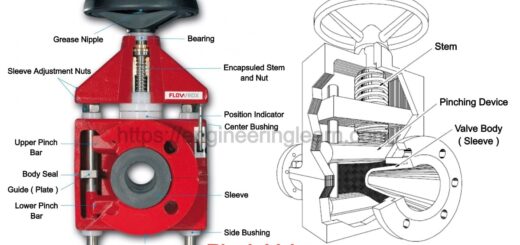

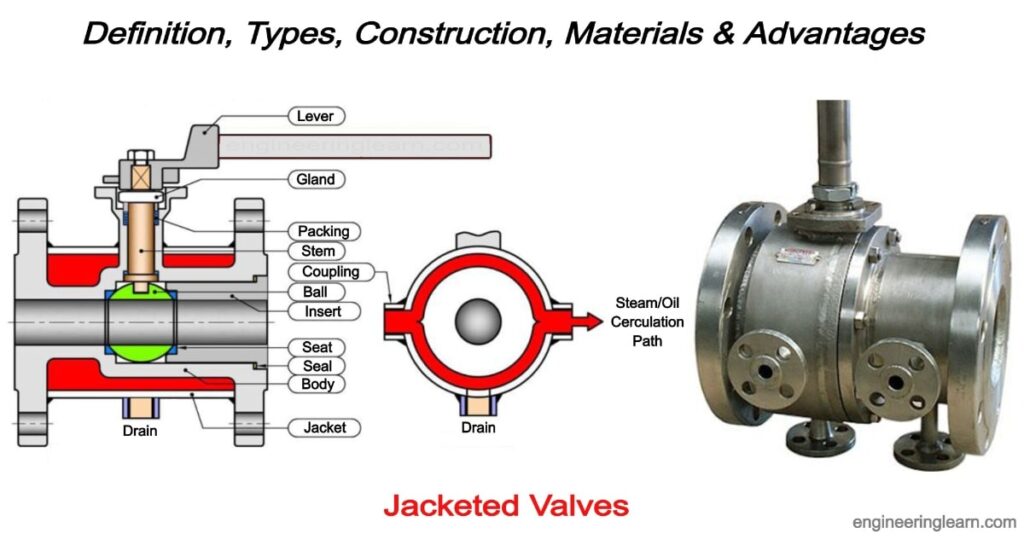

Jacketed Valves: Definition, Types, Construction, Materials & Advantages :- Jacketed valves have a protective covering around their bodies, commonly known as a Jacket. Jacketed valve is the name given to these valves because of this only. These valve’s jackets can be constructed or welded directly to the outside body of the valve. Jacketed valves are produced in a wide range of styles across the industry. Each of which applications is determined by the flow media’s level, the pressure involved, the temperature it experiences, and the industry’s performance and operation level. ( Types of Valves )

Jacketed valves are well recognized for being designed expressly for use with media fluids that have the potential to crystallise or seize. It is important to note that such valves should not be influenced by the additional heating and cooling methods.

Types of Jacketed Valves

Apart from this the operation of jacketed valves are more or less similar to the other valves. The jackets can be incorporated to the any other valves such as, ball valves, piston valves, check valve, needle valve, poppet valve, slide valve, pinch valve, manifold valve etc. But generally jacketed valves come with the ball valve setup because ball valve is very easy in operation and gives better control over the temperature of the flowing fluid. However, on the basis of temperature of media, the jacketed valves can be divided into three types;

1. Heat jacketed Valve

These valves have the jackets or pockets, welded or casted in the body shell in which the electric heating coils are present to control the temperature of the flowing fluid. These types are valves are not generally used and also not advisable to use.

2. Hot jacketed Valve

These valves have the jackets or pockets, welded or casted in the body shell through which the hot media passing to maintain the temperature of the flowing fluid.

3. Cold jacketed Valve

These valves have the jackets or pockets, welded or casted in the body shell through which the cold media passing to maintain the temperature of the flowing fluid.

Construction of Jacketed Valves

The construction of jacketed valves is similar to the ordinary valve which are being used in the industry. However, the jacketed valves consist jackets or pockets in their body through which the liquids or steams are being passed to control the temperature of the flowing fluid.

These jackets are constructed in the valve body in different shape and size depending up on the temperature control and the flow rate of the flowing fluid. An additional circulation system is required to supply the media into the jacket. The media can be cooling media or heating media depending up on the demand of the flowing fluid.

The pump discharges the media into the jackets of the valve where they perform the cooling or heating operation for the flowing fluid. The strainer collects the used media from the jackets and filter it to make it free from the contaminations. Then the media send for the heating or cooling process depending upon the requirement and the cycle goes continuous. After some fixed number of cycles, the media is changed as it loses its thermal property. Generally, steam, thermal oils, water, refrigerants etc. are used as media for the jacketed valve.

The Jacketed valves are typically available in 2-way or 3-way configurations with flanged ends. Valve ends that are screwed or welded are also available for specific purposes. Jacketed ball valves are capable of handling even the most viscous fluids that freezes at room temperature or fluids that requires some kind of temperature control.

Materials of Jacketed Valve

The jackets of the jacketed valves are available in many ally configurations such as carbon steel, low temperature carbon steel, austenitic stainless steel, duplex stainless steel and sometimes the super alloys like IN718/IN625 are also incorporated for the critical operations.

Need for jacketed Valve

Hot Jacketed valves are used to prevent the solidification of flowing fluid in a pipe line, and we all know how difficult it is to re-start a process system once fluid has been lodged in a pipe line. So, if flowing fluid solidify at room or lower temperatures, heating media are selected and sent through the cavity of the jacket to resolve the trouble operating of the plant, which is practical not achievable in a typical two-way valve.

To control and maintain the temperature of flowing fluid at lower temperature, cold jacketed valves are used. Where the flowing fluid temperature has an impact on the overall system and process of the plant, a cold jacket is used to prevent the plant from reaching its upper maximum temperature limit. This allows the plant to remain operational while recirculating cold water, which is not possible with a standard valve.

Advantages of Jacketed Valves

- Design makes it safe from fire and other hazards.

- Double sealing for better and leak proof operation

- Test implemented on to the body design

- Highly adjustable and flexible in operation

- Generally, comes with a maintenance-free seals

- Additional O-ring gives the better flexibility and adherence in the operation

- Can be designed as per the customer’s requirements and demand of the system.

- Combined with metal or the metal-based sealing system to maintain and sustain the high pressure and temperature conditions. Moreover, the abrasive operation conditions can also be managed in jacketed valves.

- Ball valve design can be customizable as per special vessel flanges

- Piping can be prepared as per customized request

- Extended stem controls

- Antistatic- Design

- Contains scraper chamfer used for cutting the viscous product

- Secure in operation

- Reliable sealing during the shut-off position

- Offers reliable sealing towards the outside portion

- Fire-safe as tested and approved

Image Source :- jacketvalve, adanac