Fuel Gauge – Types, Uses, Need & Working Principle [Explained with Complete Details]

![Fuel Gauge - Types, Uses, Need & Working Principle [Explained with Complete Details]](https://engineeringlearn.com/wp-content/uploads/2023/01/Fuel-Gauge-1024x539.jpg)

What is Fuel Gauge?

Fuel Gauge – Types, Uses, Need & Working Principle [Explained with Complete Details]: – A fuel gauge is a gadget inside a car or other vehicle that gauges the quantity of fuel in the vehicle. This equipment may measure the amount of Fuel or any other liquid form. It will generally consist of a detecting or transmitting device that detects the quantity of Fuel remaining and a gauge or indication that sends this information outside the fuel container. A Fuel gauge may be made in various ways, and many meters have many problems that can make the readings less than accurate.

Also called a gas gauge, a Fuel gauge is primarily used to communicate information regarding fuel storage to a person driving a vehicle or utilizing a storage container. For an automobile, this gauge consists typically of two elements that work together to measure the quantity of Fuel and send this reading to a driver. The two pieces of a Fuel gauge are the detecting or transmitting unit and the indication or gauge.

Working Principle of Fuel Gauge

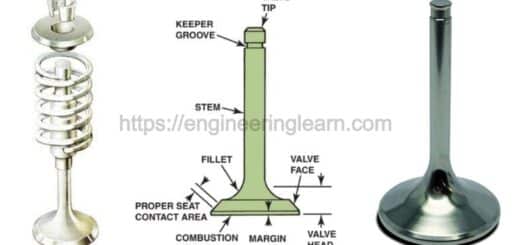

A sensing unit is the portion of a Fuel gauge situated inside or attached to the actual fuel storage container of a vehicle. On an automobile, for example, the sensing unit will consist of a float inside the fuel tank, which is attached to a metal rod that runs to a small electrical circuit. The float rises or lowers based on the fuel tank’s Fuel quantity. As the float moves, the arm is linked to the activities of a wiper that is connected to a resistor in that electrical circuit. When the tank is complete, and the float is at the top, the resistor is shifted to one side of the course, and a significant quantity of current is allowed to flow through. As the tank empties and the float lowers, the wiper travels in the circuit, the resistance rises, and the current drops.

On the opposite side of the fuel gauge, there is an indicator or gauge that shows information regarding fuel levels to the driver of an automobile. This may consist of either a bimetallic strip or a microprocessor coupled to the circuit in the sensing device. As resistance varies in the course, the current rises or reduces, and the bimetallic strip will bend or straighten out based on variations in current that raise or decrease the temperature of the strip. As the strip changes form, it will move a needle on a Fuel display, conveying that the fuel tank is empty, complete, or any quantity in between. A microprocessor can process the current variations and then send a signal to a device that similarly moves a needle.

Why Need a Fuel Gauge?

The sudden shortage of Fuel in the vehicle running fast on highways, hundreds of cars moving on busy roads of cities, air transportation, and military aircraft serving in fights at the borders can cause various problems like aircraft crashes, significant accidents and traffic jams resulting into loss of time, human resources and equipment. Thus, there is a necessity for a gadget called a fuel gauge, which tries to address all such difficulties by detecting the amount of fuel in the tank.

How does the Fuel Gauge Work?

An oil tank, metal rod, battery, and a variable resistor or potentiometer are all part of the traditional older method. You can see the whole fuel gauge wiring schematic here. Changes in resistance are the most important concept here. In a nutshell, this Fuel gauge system has two parts. The sender and indicator are two separate units.

Sending unit monitors the amount of fuel or diesel fuel and modifies resistance accordingly. Our dashboard’s digital or mechanical indication unit is nothing more than this simple piece of equipment.

A float lies on top of the Fuel in a standard automobile or motorbike tank because it is light. Metal rods and a variable resistor are connected via the float. The car battery provides electricity for the resistor circuit. The resistor is divided into sections, each with a distinct resistance value. The connecting rod’s location necessitates maintaining a constant flow of current.

The float reduces as the oil level decreases. The float is attached to a potentiometer arm or side. This has the effect of altering the circuit’s current value. The current decreases as the level rise, and the reverse is true. When the oil level declines, the resistance (ohm) increases. Consequently, the level varies when the car travels and uses more oil, and so do the resistance and current. Then, the dashboard display shows the circuit’s current. The quantity of fuel remaining in the tank is shown on the dashboard when calibrated.

Smart Systems with LED, LCD, and LCD Gauge Technology for the Digital Age

Digital speedometers and safer fuel gauges are becoming more common in automobiles nowadays. These are much more accurate and less prone to malfunctions than their predecessors. Maintenance costs are lower, and the product’s life expectancy is also increased. Additionally, the dials on them are almost impossible to break. We’ve seen folks driving around with faulty Fuel gauges that indicate either full or empty. The digital ones aren’t as vulnerable to damage. The improved precision is ideal for everyone, especially drivers and passengers.

Using the Moylan arrow as a fuel gauge indicator

Microprocessors and other electronic circuits are now often employed in modern systems to accurately detect resistance. Instead of an electromagnetism-based mechanical needle, a flexible digital screen is available. The calibrated dial in the traditional needle system is driven by a simple ammeter, which measures the system’s current. The data on the digital indicators are shown on modern LCD and LED panels. DTE is a new parameter that appears in automobiles equipped with sophisticated software (Distance to empty). Our DTE system indicates the remaining quantity of oil, whereas our old analogue gauges show our current oil level and our remaining Fuel range.

A pump sign with an arrow pointing toward the intake is also visible on the dashboard. A Moylan arrow is what you’re looking at. It makes it easier for cars to park in the right place at the gas stations. Ford was the first carmaker to utilize this feature. The internet is littered with videos of individuals incorrectly parking their cars, and it’s not hard to find examples.

Magneto Resistive Level Sensor

In regular gauges, the potentiometer’s float and flow of electricity are used. This isn’t the safest option because of the potential for a fire. The new level sensor system retains the electronics and sealed system outside the tank. The float arm of the magneto resistive fuel gauge has a magnet. When the tank’s level changes, the magnetic field picks up on the object’s movement and transmits its location. It’s very accurate and highly safe, and it modifies a mechanism used in standard Fuel gauges. This sort of sensor works on the magnetoresistance concept as its underlying basis.

Things like these will gradually disappear as we go toward battery power in the vehicle sector. Now the industry will focus on increasing the material’s energy density and developing better automobile batteries. Shortly, we may expect to see more and better electric vehicles on the road, thanks to the efforts of many nations and organizations.

Functional Principle of the Fuel Gauge

The sender half of a fuel gauge is attached to the tank, while the receiver part is attached to the vehicle’s dashboard. When a float arm, bimetal strip, or other arrangement is used to transmit a signal to a receiver, the receiver interprets that signal to display how much fuel is left in an analogue stick or digital bar.

Types of Fuel Gauges

To choose which of the available Fuel gauges is most suited for a given vehicle, consider its size and the number of tanks. Mechanical fuel gauges, for example, cannot be utilized in autos like aeroplanes and aircraft when the tanks are located at a considerable distance from the cockpit. Mechanical fuel gauges are almost impossible to use at this great distance, and they cannot be expected to provide reliable measurements. Because of this, electronic or electrical fuel gauges are employed in certain situations.

1. Electrical Fuel Gauges

One of the most common fuel gauges today is the electrical fuel gauge, which utilizes either the vehicle’s battery or electrical signals to communicate. These gauges are among the most precise in the industry.

Four sub-categories of electrical gauges are further subdivided:

A) Electrical Fuel Gauge with Flat Waves

One portion is attached to the tank and the other to the dashboard. A single wire connects the two components. A rheostat and a float make up the tank-mounted portion. With each change in tank position, the rheostat resistance varies. Coils with an armature and a pointer located at the junction of the coil axis are attached to a tank. The waves produce a magnetic field when the ignition is turned on, which acts on the armature of the pointer.

When the Fuel gauge indicates that the tank is complete, the rheostat’s resistance is at its maximum and lowest when the indicator shows that the tank is empty.

B) Thermal Type Electric Fuel Gauge

The receiving section of both the bimetal and thermal electrical gauges is constructed similarly, which is a commonality. Float controls a rheostat, a sliding contact on a resistance wire in this electric gauge. When the ignition is turned on, voltage is supplied to the two contacts in series. Unlike the gauge with balanced coils, this gauge has a lower resistance when the tank is complete and a higher resistance when the tank is empty.

To completely bend the bimetal strip, electricity travels via a rheostat with the least resistance. A higher resistance indicates that the tank is almost empty since the current flow is reduced.

C) Bimetal Type Electric Fuel Gauge

Unlike other gauges, the bimetal type electric fuel gauge has two elements. The two main components are the transmitter, mounted outside the tank, and the receiver, which displays the reading. A single cable links the two components.

The heating wire is looped around a bimetal strip, which is essentially a strip used to demonstrate temperature change by mechanical displacement. It’s based on the external float system premise. The tension in the bimetal strip varies with the float’s location, as does the height of earthed contact. The battery’s current powers the whole working unit.

D) Electric Fuel Gauge of the Thermostatic Type

The ancient types of automobiles used this style of gauge. Two wires link the transmitter and receiver. A heating coil is looped around a pair of thermostat plates in the reception section. When the ignition is turned on, it also uses the battery current. The thermostat plates flex due to the heat generated by the current flowing through the coil, which causes the indicator to move up and down the scale.

2. Mechanical Type Fuel Gauge

A direct reading gauge is a gauge that uses an internal float mechanism to measure the amount of water in the tank. The indicator’s float lies on the top of the gasoline, where it gets its name. The indicator’s float is what gives it its power. When the fuel level varies, the story of the floats changes as well, and the readout on display is also affected.

3. Electronic Type Fuel Gauge

In contrast to the other kinds of Fuel gauges we’ve reviewed, this one has a digital display. It does not have a float or rheostat that may be moved inside the tank. This fuel amount may be measured thanks to the dielectric property, which is the property of transmitting electrical force through it without the movement of fuel particles and the air vapour above it. Fuel and smoke in a tank will affect the tank’s capacity.

Conclusion

A fuel gauge is a device that indicates how much fuel remains in a vehicle’s tank. It is usually located on the dashboard, near the driver’s seat. Fuel gauges may use different technologies to measure fuel level, including float-type, sensing rod, and capacitive sensors.

Fuel gauges measure the fuel level in a vehicle’s tank. The most common type of fuel gauge is a float-type sensor, which uses a float that rises and falls with the fuel level in the tank. As the float rises, it activates a switch that turns on an electric light or another indicator to show how much Fuel remains. Other types of fuel gauges include sensing rod sensors and capacitive sensors. Sensing rod sensors use a sensing rod that extends into the tank and whose resistance changes as it comes into contact with different levels of fuels. Capacitive sensors measure the change in capacitance between two electrodes as the level of fuel changes.

The benefits of having a fuel gauge include seeing at a glance how much fuel is remaining in the tank and avoiding running out of power. Fuel gauges can also help diagnose problems with a vehicle’s fuel system. For example, if the fuel gauge needle drops suddenly while driving, it could indicate a problem with the fuel pump or filters.

Content Source: – thedrive

Image Source: – uniquecarsandparts, ubuy