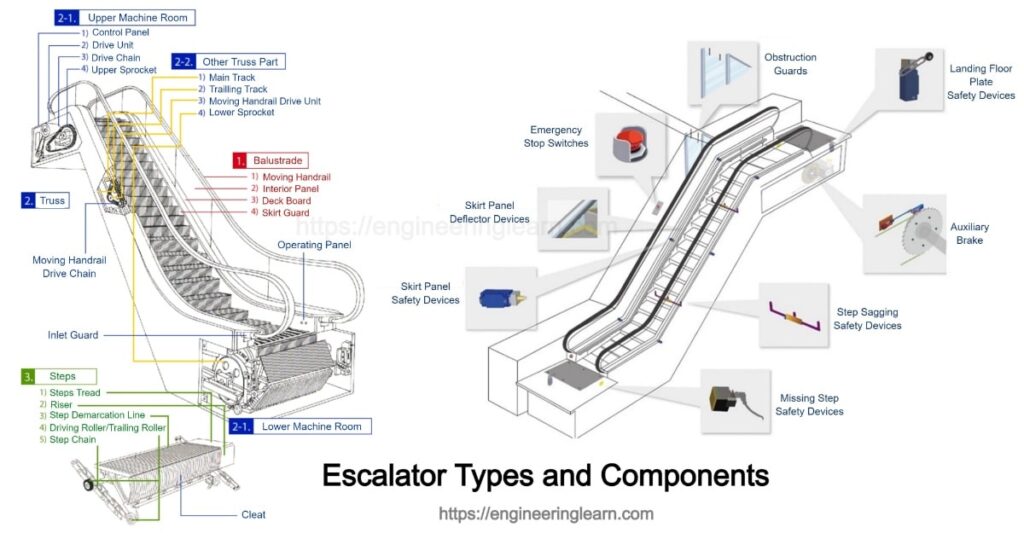

Components of Escalator [Complete Guide]

Components of Escalator :- An Escalator are simple, yet fascinating mechanical devices used for carrying people vertically between different floors. Escalator are in the form of moving staircases made up of a set of aluminum or stainless steel interlocking steps. Escalators are commonly used in buildings such as shopping malls, airports, hotels, multistory buildings, public buildings etc. Escalators contain a pair of rotating chain loops and are powered by an electric motor. These generally occupy the same physical space as occupied by a staircase and are more convenient transportation system compared to a lift or staircase. ( Types of Escalator )

At the end of the escalator, a motion sensor is connected to control the speed of the electric motor. The speed of an escalator is generally constant around 0.3-0.6 m per second and are positioned side-by-side, but move in opposite directions. The stairs of the escalators move with the help of the gears and motors attached to the escalator. The escalator system comprises of the following components:

Components of Escalator

1. Top and Bottom Landing Platforms

These are the platforms which are both curved sections of the tracks, and also the gears and motors move the stairs. The platform at the top carries a motor assembly accompanied with the main drive gear, whereas the bottom holds the return step sprockets. Other than this the platform also consists of a floor plate and a comb plate. The floor plate gives a place where the person can stand before they step directly onto the moving stairs. This plate has a well finished floor and is either hinged or made removable to allow easy access to the machinery which is installed below it.

2. The Tracks

Any proper track system is developed inside the truss that guides the step chain well and also continuously pulls up the steps from the bottom platform and back to the top in a continuous loop. There are two tracks which are installed, one is the front wheel of the steps commonly known as step-wheel track and the other one is the back wheels of the steps commonly known as trailer-wheel track.

The positions of these tracks are responsible to form a staircase as they move out from the comb plate. With the straight section of the truss, the tracks go up to their maximum distance apart. This feature forces the back of one step to be apart by a 90 degree angle which is the relative position with respect to the step behind it. This is done as the right angle is responsible for bending the steps into the shape of a stair. This is the main reason to cause the stairs in a flat sheet like arrangement, one after another, so that they can travel easily.

3. The Steps

The steps which are created are solid, mostly in one-piece, casted in aluminum. It is possible that the rubber mats might be affixed to the surface of the stair to reduce chances of slippage, and also some yellow demarcation lines which are added to clearly indicate the sharp edges of the staircase to avoid accidents. The steps of the staircase are linked to make a continuous chain so that they form a consistent closed loop with each step and able to bend at the proper time corresponding to its adjacent staircase.

4. The Railing

The railing is installed to give a convenient handhold for the people who are riding the escalator. It is installed in four distinct sections. One is at the center of the railing which is a slider, or is also commonly known as a glider ply, formed by the layer of cotton or synthetic textile. The utmost purpose of any slider layer is to allow the railing to move easily along the track. The layer adjacent to this layer is commonly known as the tension member which consists of a steel or flat steel cable which provides the handrail with the required strength and flexibility. On the top are some inner construction components, made up of rubber which is chemically treated and designed to prevent the layers from being separated.

5. Truss

The truss is a structure made up of metal that bridges the lower and upper landings. It carries the straight track sections.

6. Handrail

The railing provides a convenient support to the passengers while they are riding the escalator. Just at the middle of the railing is one more layer known as a slider layer, which helps the railing to move smoothly along its track. Handrail is generally made up of polymers or rubber.

7. Balustrade

The structure that supports the handrail of the escalator. Balustrade may be made of metal, panels or glass.

Escalator Speed (Components of Escalator)

The speed of an escalator is mostly kept constant and is generally around 0.3-0.6 m per second. Suppose if an escalator moves with an average of 44 m per minute then it can transport over 10,000 people per hour, which is a highly considerable capacity as compared to a standard lift system. A motion sensor can also be connected at the end which helps in regulating the speed of the motor powered by an electric motor. The maximum angle at which an escalator can be inclined with respect to floor level is 30 degrees and maximum up to 60 degrees depending upon the site condition.

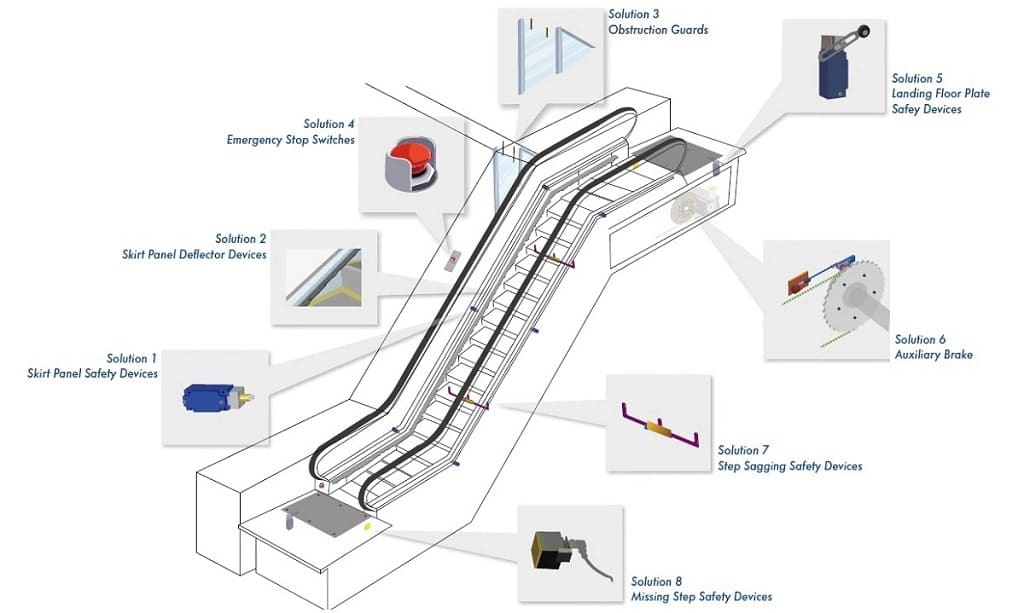

Escalator Safety Mechanism (Components of Escalator)

- Control panel

- Main track and Trailing track

The Design of an escalator system depends on multiple factors like-

- Traffic patterns.

- Location of the building

- The vertical and horizontal distance to be extended.

- Building Infrastructure.

- Safety consideration

- Carrying capacity.

Image Source :- Mitsubishielectric, emsd