Types of Plug Valve: Parts, Uses, Working Principle, Applications, Advantages & Disadvantages

What is a Plug Valve?

Types of Plug Valve: Parts, Uses, Working Principle, Applications, Advantages & Disadvantages :- Plug valve can be defined as basically a quarter-turn rotary motion valve that employs a narrowed or cylindrical plug to obstruct or open the flow. The disk has a plug outline, which has an opening to pass the flow.

In the unfastened arrangement, this bored passage is in line with the flow. When the plug is rotated 90 degrees from the unfastened arrangement, the solid part of the plug hinders the flow. The plug valve is used in place of a gate valve where the fast operation is needed. This valve can also be used in high-pressure temperature services.

Types of Plug Valves

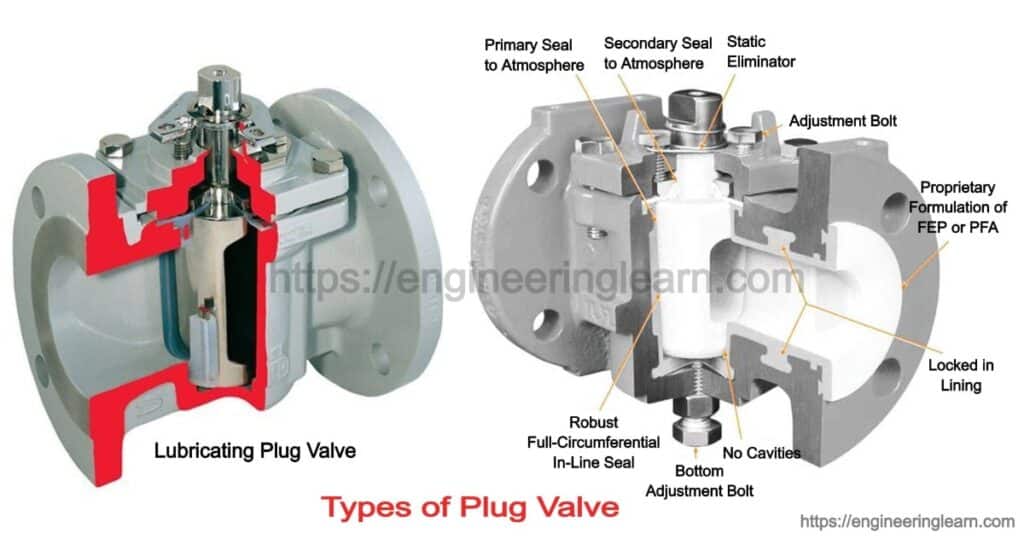

The plug valves are available in two main designs that is lubricated or non-lubricated design and with diverse styles of port apertures through the plug.

1. Lubricated Plug Valve: ( Types of Plug Valve )

The plug within a lubricated plug valve has a hollow space in the middle along its axis. This can be clearly seen in the figure below. The lubricant chamber at the base and the sealant injection fitting at the crest assures the supply of lubricant.

The small check valve beneath the injection fitting averts the sealant from flowing in the reverse direction once the sealant is infused into the hollow space. Plug surface gets continuously lubricated by the sealant that shifts from the Centre hollow space or Centre cavity through radial holes into lubricant grooves on the plug surface. The fine gap around the plug may permit leakage, and if the gap is reduced further, it will enhance the friction and plug may get jammed inside the valve body.

The lubricant lessens the force needed to open or close the valve and permits even or smooth movement of the plug. It also stops corrosion of the plug. The lubricant material must be well suiting the fluid of the pipeline. It should not dissolve or wash away by the flow medium as this could cause pollution in the fluid, and break the seal between the plug and the body, causing a leakage. Also, the sealant used must be able to survive the temperature of the flow medium.

Lubricated plug valves are available in diverse large size range, and they are compatible to work in high-pressure temperature services. These valves are employed to less wear and give better corrosion resistance in some service environments.

2. Non Lubricated Plug Valve: ( Types of Plug Valve )

The non lubricated plug valve employs a non-metallic elastomeric sleeve or liner in it. This sleeve is fitted inside the body cavity of the valve. The polished and narrowed plug functions as a wedge and pushes the sleeve against the body.

This non metallic sleeve decreases the friction between the plug and the valve body. Non-lubricating plug valves are beneficial as they demand minimum maintenance. These valves have non-metallic seat which is why these valves are not generally employed in high-temperature services. Lubricating and non-lubricating valves are competent at providing a bubble-tight shutoff. These valves have an added advantage of their small size.

3. Eccentric Plug Valve: ( Types of Plug Valve )

The design of this plug valve is made such that it employs a half plug. This half plug is beneficial for applications in which a higher seating force with minimal friction from open to closed position is required. The torque seated valves also shows characteristic improved shut off abilities. Eccentric plug valves are widely used for a flow control and isolation uses including clean and polluted water, sewage, sludge and slurries, air, and other services.

4. Expanding Plug Valve: ( Types of Plug Valve )

The expanding plug valve is a compound plug valve which utilizes a number of components that permits the valve to mechanically expand. This in turn results in a true double block and bleed function both in one valve only. The plug valve employs a mechanism that turns around between the open and closed position and shield both the seals from the flow path. During turning there is zero contact between body and seals. The slips expand onto the body seat when the valve is turned off to eliminate causing any wear or abrasion to the seals. They are often used to avoid product contamination in applications that do not require a double isolation.

5. Multiport Plug Valve: ( Types of Plug Valve )

Multiport valves are generally applied in transfer lines and for diverting services. A single multiport valve may be used in place of three or four gate valves or other types of the shutoff valve.

It is to be noted that sometimes, there are instances where the multiport valve does not entirely shut off flow. A hefty amount of care should be taken in specifying the particular port arrangement for appropriate operation.

Plug Valve Parts

A plug valve generally consists of a body, bonnet, stem, and plug. Seat is the very important part of the body in case of a lubricated type. For a non-lubricated type, a non-metallic seat is employed to enhance the leak tightness of the valve.

Plug Valve Disk Types

Plugs are of mainly two shapes; first round and second taper cylinder. These plugs may have various types of port openings, each with a different degree of the opening area.

Plugs are available with

- Rectangular Port

- Round Port and

- Diamond Port

1. Rectangular Port

This is the most widespread variety for a plug valve. The rectangular port symbolizes at least 70% of the equivalent pipe’s cross-sectional area.

2. Round Port Plug

This port has a round opening through the plug. The round port comes in full bore and reduced bore design. Valves with reduced ports are used only where restriction of flow is not crucial.

3. Diamond Port

This plug has a diamond-shaped port through the plug. These valves are venturi restricted flow type valves.

Applications of Plug Valves

- Plug valve is generally employed as on-off stop valves and provides a bubble-tight shutoff.

- The plug valve can be used in various types of fluid services such as air, gaseous, vapour, Hydrocarbon, slurries, mud, and sewage applications.

- This is also applied in a vacuum to high-pressure & temperature applications

Advantages of Plug Valves

- The design of a plug valve is uncomplicated and clear with just few parts

- This valve open and closes fast.

- The inline maintenance of plug valves is feasible.

- This valves offers minimal resistance to the flow

- It provides a dependable leak-tight service

- The multiple port design helps to reduce the number of valves needed and allows a change in a flow direction

Disadvantages of Plug Valves

- The plug valves need a higher amount of force to operate. This happens due to high friction

- The bigger plug valves cannot be operated manually and requires an actuator to operate them.

- A pressure drop is encountered due to reducing port

- The plug valves are more expensive than ball valves for any given size and class

Image Source :- assuredautomation