Types of Lime (Material): Properties, Tests and Applications

Definition of Lime

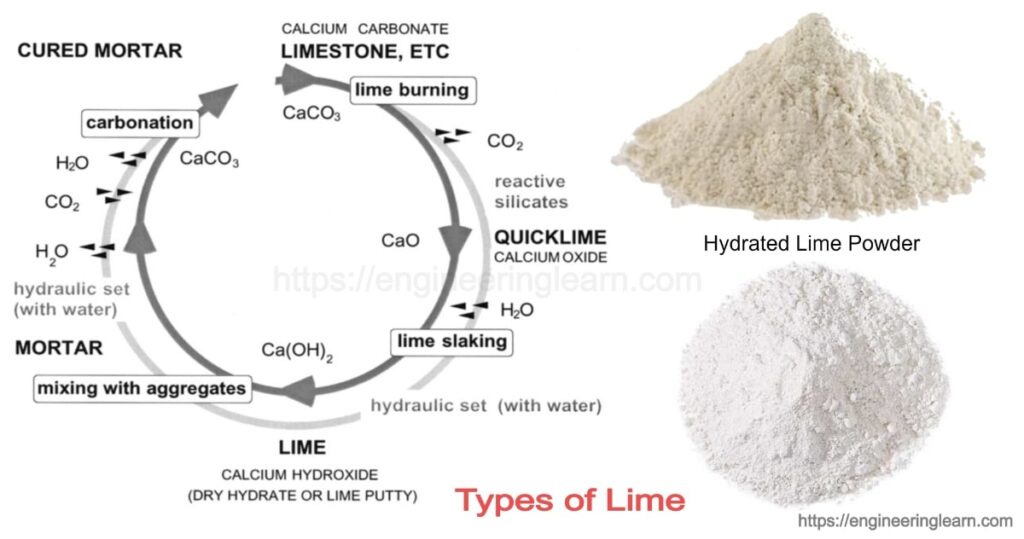

Types of Lime (Material): Properties, Tests and Applications :- Lime is obtained by calcination of limestone. The quality of lime depends on the purity of limestone. Pure limestone will give quick lime which have tendency to react with water very quickly. This quick lime reacts with water and lime is converted into powdered form along with it large amount of heat is also liberated and this process is called slaking. The slaked lime has tendency to react with carbon dioxide and a precipitate calcium carbonate is formed.

Along with lime in limestone some impurities like clay, silicates, sodium silicate and sulphate along with magnesium carbonates also found, these are known as impurities which imparts hydraulicity (hydraulicity is the property of lime by virtue of which, lime sets in a damp place with no free circulation of air) to the lime when it is in range of 8 to 30 percent.

Types of Lime & their Applications

A) Types of lime on the basis of purity

1. Pure lime (Rich lime): ( Types of Lime )

- Purity is more than 95 percent.

- They are also known as quick lime, fat lime because they have high tendency to react with water.

- High caustic lime (because of high percentage of purity).

- Vigorous slaking takes place when water is added.

- The color is perfectly white and also called white lime or milk of lime.

- High plasticity.

- Slow setting takes place because purity is very high.

- They are used in aesthetic appearance like whitewashing, plastering.

2. Hydraulic lime: ( Types of Lime )

- Purity is in between 70 to 90 percent.

- Slow slaking due to the presence of impurities.

- Setting is fast due to the presence of impurities.

- They have off- white color.

- They are used in Brick masonry, Stone masonry, lime concrete etc.

3. Poor lime or lean lime: ( Types of Lime )

- Purity is less than 70 percent.

- Binding ability of this lime is poor.

- Slow setting and slow slaking due to the presence of very high impurities.

- They have muddy white colour.

- They are used for inferior works like brick works around foundation etc.

B) Types of lime on the basis of IS 712: 1984

1. Class A: ( Types of Lime )

- It is eminently hydraulic lime.

- It must have minimum compressive strength of 1.75 N/mm2 and 2.8 N/mm2 at 14 days and 28 days respectively.

- Initial setting time: 2 hours.

- Final setting time: 2 days.

- It is used for masonry works where more strength is required.

2. Class B: ( Types of Lime )

- It is a semi hydraulic lime.

- It must have a minimum compressive strength of 1.25 N/mm2 and 1.75 N/mm2 at14 days and 28 days respectively.

- It is used for masonry works.

3. Class C: ( Types of Lime )

- It is known as fat lime.

- Used for white washing and plastering.

- Its properties are given in above classification.

4. Class D: ( Types of Lime )

- It is a magnesium dolomite lime.

- Their purity is high.

- They are used in aesthetic appearance like whitewashing, plastering.

5. Class E: ( Types of Lime )

- It is a kankar lime.

- It is used for masonry works.

6. Class F: ( Types of Lime )

- It is a siliceous dolomite lime

- It is used for white washing.

Use of lime

- White washing (fat lime)

- Plastering (for better pore refinement)

- Masonry work

- Glass manufacturing

- Water treatment Plant

- Soil Stabilization

Testing of Lime

1. Visual Test: ( Testing of Lime )

- It is performed from physical appearance of a lime.

- If the color of lime is off white then the lime is Class A lime or hydraulic lime.

- If color is slightly clear than off white then it is Class B lime.

- If color is perfectly white then lime is Class C lime or fat lime.

2. Ball Test: ( Testing of Lime )

- In a ball test, water is added in lime and stiff lime is formed. Then from stiff lime a ball of about 40mm diameter are made and kept as it is for 6hours after 6hours the undisturbed ball are kept in a basin of water.

- If there is slow expansion and slow disintegration of ball within a minute then it show Class C lime.

- If there is very small or no expansion and numerous crack then it indicate Class B lime.

- If it remains in its shape and ball crack then the lime is of Class A.

3. Hydrochloric Acid Test: ( Testing of Lime )

- It is done to calculate the presence of impurities

- 1 spoon fine dried lime is kept in a test tube and 10 ml HCL of 50 percent concentration is put into that test tube.

- If lime get mixed in it completely then it is pure lime or Class C lime.

- If there is some precipitate in bottom of test tube then it indicates the presence of some inert material. As the quantity of inert material increases the quality of lime decreases.

- If the jelly of lime and HCL is thin then it is Class C lime.

- If the jelly of lime and HCL is very thick then it is Class A lime.

- If jelly of lime and HCL is moderate thick then it is Class B lime.

4. Soundness Test: ( Testing of Lime )

- Aim of the soundness test is to find disintegration or unsoundness of a lime sample.

- It is performed by using Le Chatelier’s apparatus where lime is properly.

- Cement, Hydrated lime and sand is thoroughly mixed in the proportion of 1:3:12 and then this mixed is filled in a cylinder of a Le Chatelier’s apparatus. Cylinder is covered by a glass plate and kept for 1hour and the distance between the two ends of indicator is properly measured and noted.

- This apparatus is kept for 48hours in damp air and then kept for 3hour in steam. Then the temperature is cooled down to room temperature. The distance of the two end of indicator is again measured and noted. The difference between the two distances is found out and it should not be more than 10mm.

5. Transverse Strength Test: ( Testing of Lime )

Test sample of size 25mm x 25mm x 100mmia prepared by taking lime and sand in 1:3 proportion. Then test sample is kept for 28days at 90 percent humid medium. Test sample is immerged in water for 30minutes before going to be tested. Then sample is restrained on a two parallel roller kept 80mm apart from each other, then the test sample is loaded by gradual increasing load at a rate of 75 N/ minute till the test sample are failed. The modulus of rupture of test sample can be determined by using the formula

E = 3PS/2bd²

Where E = Modulus of rupture

P = Breaking load

S = Distance between the roller

B = Width of the specimen

D = Depth of the specimen