Types of Extruders: Application & Working Principle

What is Extruder?

Types of Extruders: Application and Working Principle :- Extruders are one of the most important component which is used in the manufacturing process. Whenever these are combined with feeding, cutting, de-airing or other form of equipment it can create everything. There are various types of extruder machines about which one must know. So scroll down to learn more. ( Types of Extrusion Process )

Types of Extruders

1. Single Screw Extruder & Twin Screw Extruder

There are two types of extruders which are mostly know. First is the single and other is the twin screw extruder. Twin screw extruders are those which offer counter rotating. These come along with a very wide range of screw dimensions and designs. The single screw and the twin screw both are axially open-channel extruders as they can be regarded as the drag flow pumps.

If the output or degree of fill is not found running at the maximum volumetric rate it can be impacted by the pressure flow within the extruder. The counter-rotating twin screw extruders are found forming a closed channel inside the intermeshing region as the output is less vulnerable as compared to the pressure flow within the extruder. They are considered to be having positive displacement pumps.

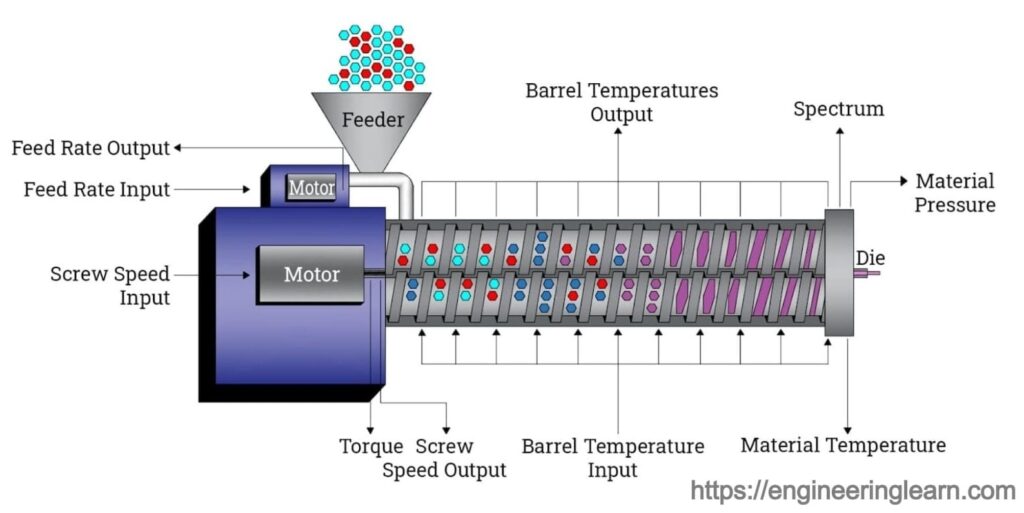

Function of Single Screw Extruder

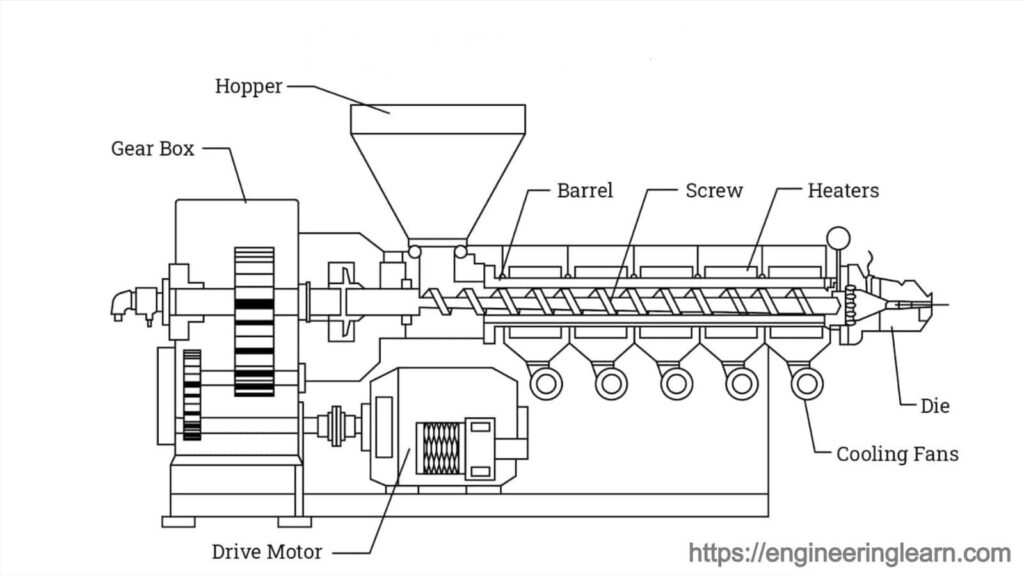

The main function of the extruder is to convert the solid plastic into a uniform melt by the effect of heating, pressurizing and shearing after which it is send to the next process. The procedure of melting involves processes like mixing color, master-batches, blending resins and re-grinding. The finishing should mandatorily be done uniformly in concentration and temperature. The effect of pressure must be large enough in order to squeeze the viscous polymer.

The extruder is responsible for performing all of the above processes with a barrel, screw and a spiral knife. The plastic pellets get in to the barrel via hopper which is placed at one end of the barrel and then are passed through the screw to the other end of the barrel. For maintaining the pressure, the depth of the threads on the screw is decreased as the hopper keeps on increasing.

Principle of Twin-Screw Plastic Extruder

The twin-screw extruder works on a principle of an extruder for a single-screw extruder wherein the process like transport, melting, pressurization, pumping, mixing, stripping and de-volatilization are all conducted due to these extruders. A recent research on the twin-screw extrusion theory stated the complexity of the screw’s geometry and the process of extrusion was also found to be very complicated which brought many difficulties in the research.

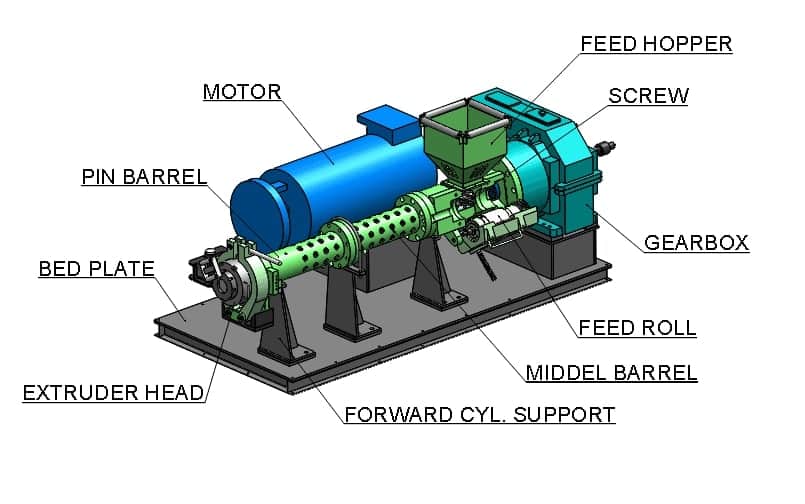

2. Rubber Extruders: ( Types of Extruders )

The manufacturers who deal with the material like rubber bales, silicone and EPDM are aware that breaking them is the hardest thing which anyone can do. These are the materials which generally come in large quantities due to their stickiness and also require a very special chemical or talc which needs to be formed into manageable sizes and consistencies.

After the collaboration with the some of the companies, the custom extruders were designed specifically for the machines according to their sizes and the manufacturing needs were improved and controlled. In case there are any tight space constraints, then there are compact solutions to meet the site requirement.

3. Food Extruders: ( Types of Extruders )

In the food industries, it is essential to have a high volume of consistent products which is created with the appropriate safety and efficiency standards. The types of extruders are designed for cooking and cooling food which has helped the food production process in various ways. For instance, a food extruder machines eliminates batch cooking by consistently cooking semi-moist, moist, dry and pre-mixed foods with a high temperature, pressure and timing precision.

Once it is combined with a custom extrusion dies and extrusion cutters, the same unit is used to create an unlimited variety of food pellet in varying shapes and sizes. In terms of safety and longevity, the food extruders are made with the material stainless steel in order to ensure the sanitary production and less downtime for replacing the parts.

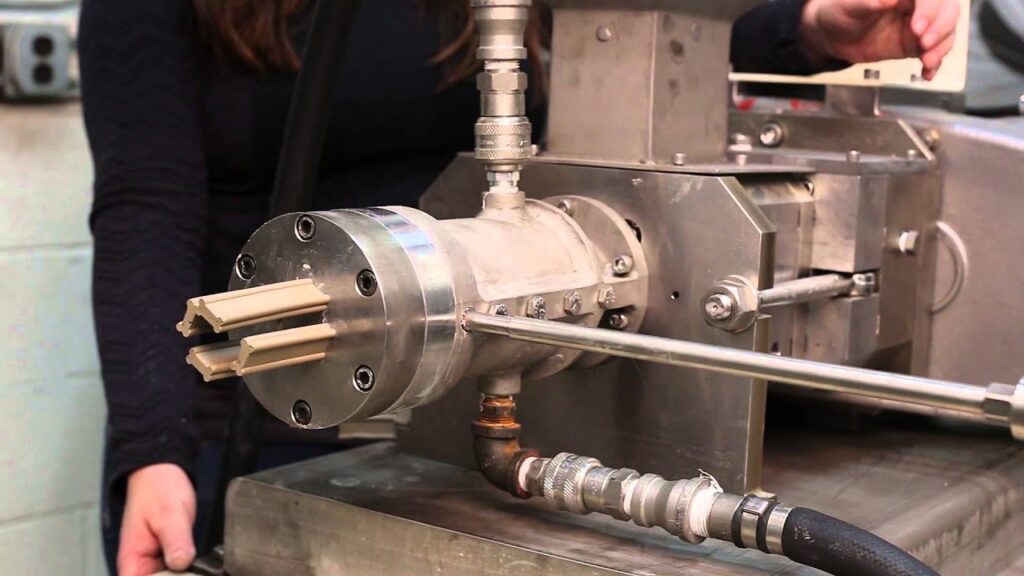

4. Lab Extruders: ( Types of Extruders )

There are various types of extruder units which are in the need of production in small batches of materials, like in the testing departments across the industries. These type of extruders are quite small in dimension and are found to be table mounted in order to meet the needs of any lab space or facility layout.

The lab extruders are mostly used in creating the activated carbon for air and water purification. These are found having a wide range of part shapes and sizes which includes auger, barrel, screw and die configurations. Depending on the need of constructing it in different materials like stainless steel or carbon steel is available. The potential for customization in lab extruders is almost limitless.

5. Catalyst Extruders: ( Types of Extruders )

The catalyst extruders are used from refining crude materials to changing its molecular structure, as catalysts are found to be a very crucial part of a production process. The types of extruders which are used in the catalyst industry are unmatched in their level of customization. The extruder models are available in various bench-top sizes whereas the standard sizes are 4″, 6″ and 8″ sizes for high volume production.

Jacketed barrels are also designed for a specified level of heating or cooling requirement, along with the custom auger and barrel dimensions. The level of customization in the final product will help in sustaining the operational requirements in order to meet the exceeded peak load specifications.

Applications of Extruder

- Most of the extruders are found having their application in the food industry. The design and the specifications of an extruder should be tailored for an intended application from simple forming applications like Italian food, to simple cooking extruders for corn curls, to more complex as well as long extruders which may involve multiple operations that can result in significant modifications of any extruded material.

- The material of extruders feed can include a single solid or many solid and liquid ingredients. For instance, the solid ingredients which can be included are grains, pulses, root-based foods, sweeteners, minerals, and vitamins which are utilized in a variety of particle size distribution. The liquids are found having the water content always including oil, liquid sweeteners and colors. All these ingredients are properly mixed and converted into a melt or dough and then are formed into the desired product shape.

Extruder

- Using the extruder for a combined usage like cooking and cold forming of unexpanded products is a usual process which is used to make snacks, cereals and other products. The accelerated cooling of an extruder before the final forming step is quite critical in such operations. This process is done by evaporating the liquid present in the water in a venting stage either within a single extruder or within a cooker and a forming extruder. The selection and design steps of these steps are briefly explained.

- Once the extruded product is developed on a small production basis, the scale-up is then the part of the total selection of an extruder including its design process. The impact which a scale-up process has is discussed by identifying the important factors, limitations and the additional process options.

- The die plate assembly is referred to as a vital part of the total extruder design which is directly responsible for forming the desired product shape and simultaneously acts as a flow resistant which is found impacting the output or degree of fill, energy input and thus results in material transformations of an extruder.

Working Principle of Extruder

With the rising application and development of extruder molding processes, the types of plastic are increasing along with the classification methods which are also inconsistent.

- As per the spatial position of the screw, it can be divided into two types first is the horizontal and second is the vertical extruders.

- According to the rotational speed of the screw, it can again be divided into three types, first is the ordinary extruder second is high speed extruder and third is the over-speed extruder.

- As per the number of screws, it gets divided into screw less extrusion like machine, single screw extruder, twin screw extruder and multi-screw extruder.

Stage 1

Whenever the extrusion system is heated to a given process temperature for a fixed period of time, the motor gets started and the torque and the speed which is required by the screw is supplied to the screw. The plastic present inside the hopper enters the groove by the feeding port under the action of its own weight or the thrust of the feeder. As soon as the screw rotates, the plastic is transported further under the action of the friction of the barrel screw.

Stage 2

Once the self-feeding port gets entered, it is moved forward due to the effect of friction in the inner wall of the cylinder from the surface of the screw under the action of the decreasing friction. During the molding process, the material is added from the hopper to the plastic extruder in either powdered form or granules. This is the process of conveying, compacting, compressing, melt plasticizing and homogenizing into a uniform melt which gets completed. All the loose solid pellets are filled with the screw groove because the material is continuously conveyed and begins to be compacted.

Stage 3

As soon as the material enters the compression section, the plastic eventually increases the amount of pressure due to the shallow depth of the screw groove along with the resistance of the head which is further compacted at the same time. Heating the barrel outside and the inner surface of the screw and the barrel under the action of internal friction and shear, the heat which is generated by the strong agitation, mixing and shearing friction is observed to increase continuously and after it, at a certain point gets in contact with the barrel. The temperature is found reaching the melting point and where the material starts to melt.

Stage 4

Once the material is transported the heating still continues and the amount of molten material increases eventually whereas the amount of material that is not melted decreases accordingly. At the end of the compression section all such materials is transformed into a viscous flow state wherein the temperature at each point is not uniform but the homogenization of each section is relatively uniform. At last the screw quantifies, constants and determines the temperature of the molten material. The die which is present inside the head of the plastic extruder is a molded part which goes through the material which is responsible for obtaining the geometry and the size of a certain section. Once the section is cooled and all the other processes are done, the product which is formed can be obtained.

The extruder is usually found having three stages.

- The first section which is near the hopper, is referred to as the feeding section. Its function is to just allow the material to enter the extruder at a relatively smooth rate. Generally, this is the part which maintains a relatively low temperature so that the blockage of the feed channel can be stopped.

- The second part is referred to as the compression section, wherein the melt is formed and the pressure is purposely increased.

The last part of the metering section is close to the exit of the extruder. Its main function is to maintain a uniform flow out of the material in the extruder. In order to ensure the uniformity of composition and temperature, the material must have sufficient residence time. At the end of the barrel, the plastic which is melted exits the extruder through a hand-piece which is particularly designed with the desired shape through which the extruded melt stream passes.

Another foremost important part is the drive mechanism of the extruder which is responsible for controlling the rotational speed of the screw and also determines the output of the extruder. The amount of power which is required is determined by the viscosity of the material. The viscosity of the any material depends up on the temperature and the rate of flow which decreases with the increase in temperature and shear. The extruder is found having a strainer which blocks the impurities of the screen.

Image Source :- loyalfoodmachine, rubbermachineryworld, iqsdirectory