5 Types of Brake Pads – [Explained with Complete Details]

![5 Types of Brake Pads - [Explained with Complete Details]](https://engineeringlearn.com/wp-content/uploads/2023/01/Brake-Pads-1024x539.jpg)

Introduction

5 Types of Brake Pads – [Explained with Complete Details]: – Brake pads have been used for a long time for braking purposes in an automobile. It has been developed in the past few years to the extent that its usability has only gone up in the past few years. There have been many types of brakes in use these days like disc brakes, shoe brakes, pad brakes, simple band brakes, and differential brakes, and each one of them has been as per the user requirements.

Brake rotors of a simple brake rotate with the wheels with the brake pads clinging on the sides to put in action as and when required. The brake pads are fitted to the brake calipers and clamp-on these rotors to stop or decelerate the wheels. The brake pads pushing against the rotors generate friction due to physical contact between the two of them and this leads to considerable heat loss. The reduction in kinetic energy translates to thermal energy. The energy losses correspond to the machine’s power loss which can be minimized using several techniques, something which is beyond the scope of this article for now.

The heat generated is usually taken in by the brake pads and the surrounding atmosphere. The heat needs a place to dissipate and the brake pads provide that medium. Therefore, with time brake pads undergo considerable wear and tear. This led to the development of newer and more efficient brake pad designs that can tolerate a higher level of thermal energy for prolonged periods. This is usually augmented by using newer materials for the construction of brake pads.

A common notion of brake pads is that it is made up of rubber-like material that has to be changed and replaced after using for a certain amount of time. But in light of the recent developments made in making new materials for brake pads, the age-old notion doesn’t hold. There have been considerable upgrades in brake pad materials that have made life easier for engineers and service mechanics. The access for the brake pad to the outer atmosphere reduces its damage as the heat generated can be dissipated outside. The brake pad is known to be impervious to water and moisture which further adds to its list of advantages.

Construction of a Brake

The brake rotor disc rotates with the wheel and is clamped by the brake pads which act as a friction material. It is fitted to the brake caliper from both sides with pressure being applied every time the driver wants to reduce vehicle speed.

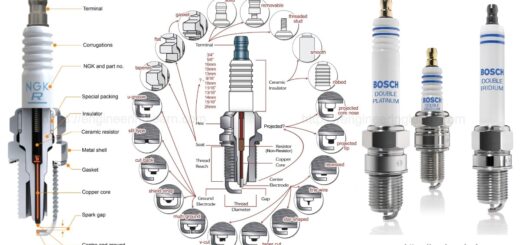

Brake pads are the machine component that pushes into the rotor, thereby creating friction that slows down the car. It contains a metal feature called the shoe and a lining that is attached to the shoe. This lining is what comes into direct contact with the rotor and wears away with successive use. Shoe linings can be made of different materials and come under 3 categories: organic, semi-metallic, and ceramic.

Types of Brake Pads

1. Ceramic Brake Pads: ( Types of Brake Pads )

They have been giving superior performance in tough conditions for quite some time now. Even though a bit expensive, they are known to be long-lasting that making up for the high costs attached to them. The ceramic padding that comprises the body of this type of pad is great at absorbing a high amount of heat at elevated temperatures for a sustained time.

They are more prone to conditions of tough braking due to the material properties that give them an edge over other types of brake paddings. In high-speed racing cars, where dynamic braking is the prime need, these brake pads have a successful service record. They are made of small amounts of copper and clay which gives them better heat conductivity properties. The overall wear and tear of such kinds of paddings are quite slow which further adds to its attractiveness of it for large-scale use.

They are less noisy as compared to other paddings available in the automobile industry. They also have an added benefit of low dust production with time due to material wear. This adds to its overall benefits even though on the flip side, such paddings are a bit pricey owing to the superior technology inherent in them.

2. Non-metallic Brake Pads: ( Types of Brake Pads )

They are the softest type of pads available with traces of rubber resins and glasses along with some quantity of metal fibers. The flux coating on it can wear away with time due to high temperature and operating pressure. Due to this, they are only used for regular driving with no special purpose driving being attributed to them. Due to their softcore, they are usually not preferred for vehicles that have to go off-roading on a regular basis as that would require higher amounts of durability which isn’t something expected out of non-metallic brake pads.

3. Low-metallic Brake Pads: ( Types of Brake Pads )

Such types of brake paddings have been known to be a bit noisy as compared to ceramic paddings. The material dust created is also on the higher side because of metal-to-metal contact that is bound to generate a lot of heat that further leads to increased wear of the paddings. However, they have excellent heat transfer characteristics with the ability to dissipate heat generously. They have a generous amount of copper and steel that further elevates their heat transfer properties. They are made up of organic materials with no synthetic materials or alloys added to them to induce the desired properties into them.

4. Semi-metallic Brake Pads: ( Types of Brake Pads )

This is the type of padding that is the most widely used in the modern era. Most of the automobiles that we see on roads use this technology. They are manufactured using a combination of metals and synthetic fibers which gives the padding the best of both worlds. An organic resin seal binds all the materials together which are then molded together and heated in the furnace to bind them permanently. Such types of paddings are very durable with excellent heat-resistant properties in them that make them the ideal pick for high-speed automobiles.

However, the cold starting condition is a bit more prolonged in such paddings as their coefficient of friction is very low as compared to metallic brake paddings. Therefore, while operating at low temperatures, these brake paddings need to be given a bit more heat energy to make them operative.

Semi-metallic brake pads can be made of sintered graphite, iron, and steel which can give some more high-performance capabilities to the vehicle in question. Due to the high quantities of metal present in them, the metal-to-metal contact wears down the brake paddings very quickly as compared to other types.

5. Non-asbestos Organic Brake Pads: ( Types of Brake Pads )

They are made up of high-temperature resistant material coatings such as resins that provide better thermal stability at higher temperatures. They are less noisy and make more dust as compared to the semi-metallic brake pads. They are quieter and softer than the semi-metallic type which makes up for the other disadvantages. The usage of such brake pads depends on the relative advantage that the owner can find in them.

They are made of strong fibers that make up for the negative points it has in them. Even though they are known to make a lot of dust, they have been in use for the past many years and have had a good reputation for being good on money.

Content Source: – lemonbin, howacarworks

Image Source: – forbes