Slide Valve: Definition, Types, Working & Limitations

What is a Slide Valves?

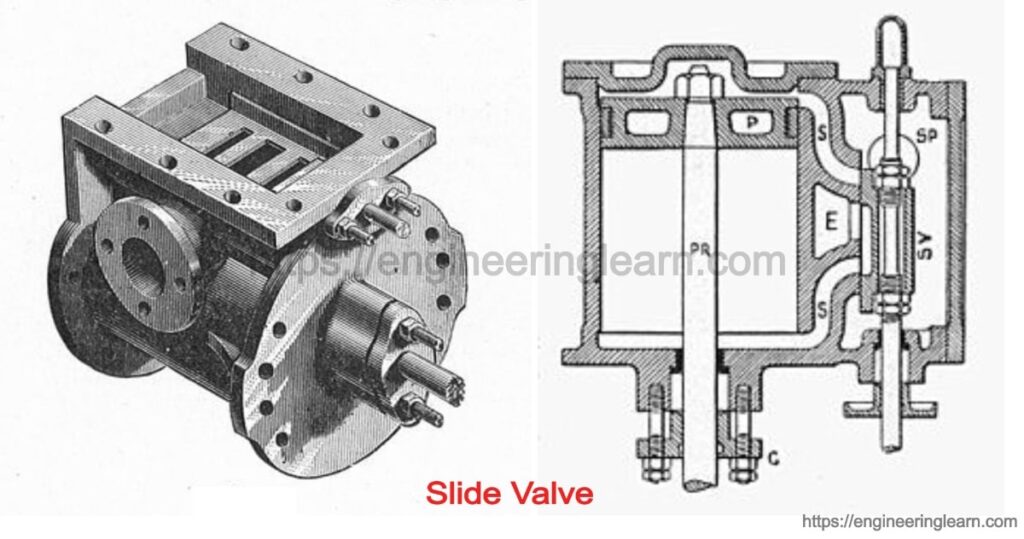

Slide Valve: Definition, Types, Working, Limitations :- Slide valve is a valve which incorporates the sliding mechanism for the purpose to control the flowing fluid through the valve. The sliders of the valve move in rectilinear path to cover and uncover the inlet or outlet port. The slide valve operates by the help of slide valve crank which is connected to the engine crank and extracting power from there to operate.

How Slide Valve Works in a Steam Engine?

To allow steam to enter the engine and exhaust to depart through the ports, or openings, at the top of a single cylinder, the valves slid from side to side in sync with the other moving parts. When the slide valve is slid to one side; the intake port is revealed, allowing steam to enter the cylinder. The steam inside the cylinder presses on the piston, which in turn pushes on a rod that turns the flywheel. The flywheel spins in order for the steam engine to move. When the slide valve moves to the other side, it uncovers the exhaust port and releases the steam while the piston again slides back to its initial position and start the process again.

Types of Slide Valves

Basically, there are two kinds of slide valves that are available for the use; D-slide valves and balanced slide valves.

1. D Slide Valve: ( Types of Slide Valves )

The D-slide valves are named because of the hollow central D-sectioned piston. This valve worked by connecting the upper and lower valves so that they can be handled by one rod or spindle, and making the stem or tube that links them hollow, so that it can act as an induction pipe to the upper end of the cylinder. This allowed two valves to perform the functions of four valves. The preceding description (which refers to upper and lower valves) definitely refers to a vertical cylinder engine, such as a beam engine. The valves would be side-by-side where the cylinders are horizontal, as in a steam locomotive.

2. Balanced Slide Valve: ( Types of Slide Valves )

The balanced slide valve incorporates the balancing rod at each side of the valve. Because of this, the forces acting on the valve are balanced by relieving pressure on the back of the valve, hence reducing friction and wear that extensively occurring in common slide valve.

Why Slide Valve Became Obsolete?

Slide valves are used in car engines to let fuel and gas into the cylinders and allowing exhaust gases to depart. The poppet valve, which move up and down on spring, are commonly used in automobiles and fulfil the same purpose. On steam engines, slide valves were pushed back and forth by a rod rather than springs. Slide valves were eventually replaced by piston valves. Despite their comparable function, piston valves had a few advantages over slide valves.

Limitations of Slide Valves

The path in which a slide valve is operated had to be fairly long, and moving the valve back and forth required more energy. This movement necessitated a lot of lubrication to keep the valves from sticking or slowing down and triggering an engine fault.

Piston valves, on the other hand, could be used in shorter passage and were much easier to lubricate. The steam engine’s efficiency improved as a result, and the slide valve became less frequent.

The use of superheated steam – steam produced at a temperature above the boiling point of water – also contributed to the decline of slide valves and the growth of piston valves. The lubrication required for the slide valves was hampered by the extreme heat. These previous valve types have been replaced by more efficient valves in modern machinery.

Image Source :- Wikipedia