Laser Marking Machine: Definition, Types, Application, Advantage & Disadvantage

What is Laser Marking Machine?

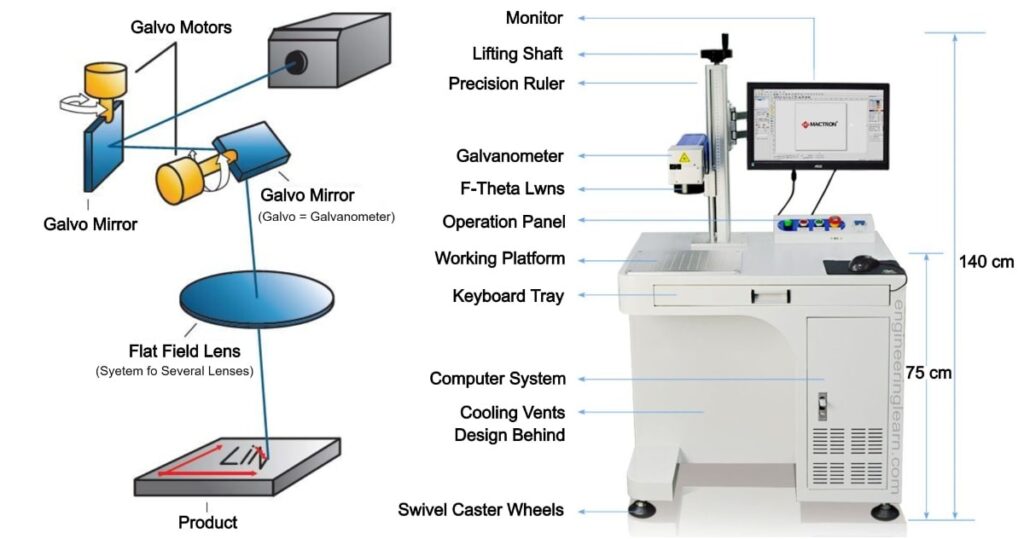

Laser Marking Machine: Definition, Types, Application, Advantage & Disadvantage :- In laser marking machine, the process of laser marking takes place which require concentrated light beam for creating lasting mark on the surface. It is generally performed with the help of pulsed, fiber, green, continuous wave or UV laser machine. Laser marking are done on variety of materials such as titanium, steel, copper, aluminum, plastic, ceramic, wood, glass and cardboard. Marking is done in machine readable data like graphics or unique ID codes, barcodes and 2D data matrix codes.

General Description of Laser Marking Machine

In laser marking machine a focused beam of light is used for marking the material’s surface. As the beam come in contact with material it changes the properties as well as appearance of the material. The beam focused by the laser marking machine target the specific area which results the machine to create high contrast, precise and high quality mark which can easily scan on virtual surface or readable. Due to this feature, laser making machines are best suitable for the applications in which permanency and accuracy is required.

Laser

The beam of laser starts as a atom which is stimulated for releasing particles of the light and the light are directed in concentrated form toward the laser marking area. The released energy are measured in nanometres or wavelengths. Lower is the wavelength, less powerful the beam of laser and vice versa.

For example: With the wavelength of 355 nanometre, UV laser marker have less power which is used for marking the heat sensitive materials like glass and plastic and are suitable for soft and organic products due to the less chances of burning of material.

With the wavelength of 1070 nanometre, fibre laser have significant power of marking hard materials like metals. Laser marking does not need maintenance in comparison to labelling or printing.

Types of Laser Markers

Types of laser marking machine needed for different material are different, this is because laser engraving are performed on various of materials such as plastics, types of metal, wood, glass, ceramic, paper and stones.

The different types of laser markers are:

1. Fiber Laser

This marking technology is widely used in these days. The power level required by the fiber laser marking machines are in the range of 20 watts to 50 watts and in this power range these are the most powerful laser markers among all others. Fiber laser are well suited for engraving or depth etching. They are commonly used on hard metals or when high resolution is required with high power. Small spot sizes and high beam quality enable them to used for cutting thin metals or batch marking applications of small components.

2. UV Laser

The wavelength range between 100 nm to 400 nm in electromagnetic spectrum represents Ultraviolet. They are longer than X – rays but shorter than the visible light. Ultraviolet whose wavelength is higher are not used as ionizing radiation due to lack of energy in its photons for ionizing the atoms and they can results in chemical reaction which can make substance fluoresce or glow.

Diodes, solid state lasers and gas lasers are used for making machines which emit UV rays. UV laser marking machines are generally designed in wavelength of 355 nm and they can mark several materials. They are well suited for the applications of cold marking in which heat production due to lasers are not applicable. They can mark materials such as glass, ceramics and plastics.

Others Type Laser Markers

3. Green Laser

4. CO2 Laser

5. MOPA Laser

Factors taken into consideration for the selection of correct laser marking system

- Stationary or moving marking surfaces

- Line speed: Because of the different properties of the power and laser wavelength, different results are obtained on the basis of speed in which the part production is happening. High wattage markers are required by the high speed production lines for efficiently marking all in process parts.

- Material on which marking is required: The selection of marker are heavily depends on the materials on which marking is required. For example: CO2 lasers are well suited with non metals while the fiber lasers are well suited with the metals.

- Conditions of environment: Some of the marking machines are sensitive to the environment in which high dust, vibrations and shocks are expected but there are some marking machines which are robust and they can resist these environment conditions.

Application of Laser Marking Machine

Laser marking machines are used in various of applications. Some common applications of laser marking machines are:

- Etching

- Foaming

- Engraving

- Annealing

- Discoloration

- Color marking

- Carbon migration

- Day and night marking

Advantage of Laser Marking Machine

- Laser marking machine provide eco friendly as well as clean process.

- Laser marking machine gives permanent identification for the parts therefore they do not need to be performed again.

- These are contact less due to which chances of contamination are very less.

- They are able to mark stainless steel in various different colours.

- They provide high accuracy because they are controlled by computer.

- They provide high contrast and homogeneous marking on some plastics.

- For marking ceramics, epoxy resins and semi conductors green lasers are ideal.

Disadvantage of Laser Marking Machine

- They have high initial investment.

- They can perform laser marking in only two dimensional axis.

- Not suitable for deep engraving in most of the metals.

Image Source :- linxglobal, mactron-tech