Globe Valve Types and Parts

Introduction of Globe Valve

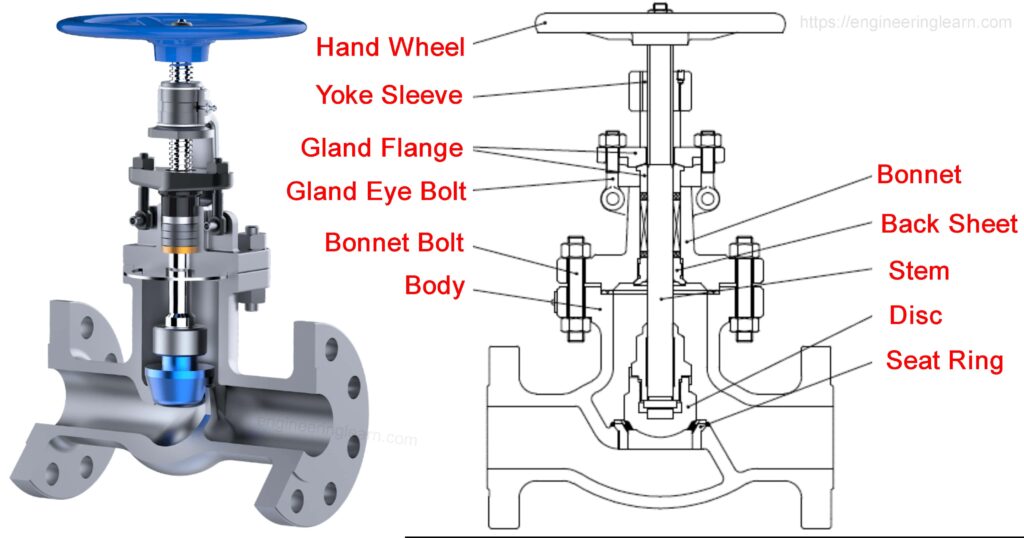

Globe Valve Types and Parts:- The Globe valve is another very important and useful type of valve. It is known as a globe valve due to its spherical shape but nowadays it has lost its spherical shape but still due to the same internal parts we call it a globe valve. The globe contains a seat and plug arrangement. It is used to start, stop, and also to regulate the flow of fluid. Due to its perpendicular flow path of fluid, it is very good at throttling also. It provides less leakage problem than the Gate valve. The globe valve gives a very high pressure drop due to the perpendicular flow pattern as you can see in the figure below.

Globe Valve Parts –

Globe valve contains many different parts like bonnet, body, stem, seat, plug, etc. Let’s discuss all of them.

- The body is the primary pressure boundary of the valve. It keeps all the internal parts together inside it. It is connected with a bonnet.

- The bonnet is connected with the body through bolts or screwed. It is a secondary pressure boundary. The stem moves vertically inside the bonnet and opens and closes the valve. It contains packing to eliminate leaking.

- The plug is the element that throttles the flow of fluid. It is connected with the stem and opens and closes by stem movement. In the close condition, it fits on the seat and stops the flow of fluid.

- The stem is the connector between the actuator and plug. By rotating the actuator we can open and close the valve by plug movement.

- The seat is the part of the valve where the plug fits and stops the flow of fluid.

Applications of Globe Valve –

It is used in many different industries and applications like

- the cooling water system

- Fuel oil system

- Feedwater system

- Chemical feeding system

- Turbine lube oil system

Globe Valve Types

Different types of Globe valves are available in the market. We will talk about all of them in brief.

1. Based on Disk closing arrangement there are two types of globe valve available

- Disk close against the flow direction: Here, the disk closing is retarded by the flow of fluid, and an opening is catalyzed by the flow of fluid. It is shown in the figure.

- Disk close in the flow direction: Here, disk opening is retarded by the flow of fluid, and closing is catalyzed by the flow of fluid. It is shown in the figure.

2. Based on the type of plug design used

- Ball Type contains a rounded plug that fits on the seat. It is not so good at throttling the fluid so mainly used for on and off purpose.

- Needle type is very good at throttling and regulates the flow very preciously.

- Composition type is a mixture of both types of disc. It Achieves better shut off.

3. Z-type Globe valve

It is the simplest type of globe valve. Here the disk is connected to the stem and moves perpendicular to the valve axis due to that it gives a very high pressure drop. It is used when there is no problem with high pressure-drop. It is very good at throttling fluid. Due to perpendicular, angles fluid pressure drop is very high.

4. Angle type Globe valve

It is the same as a Z-type valve with some modifications. The fluid flow path contains a 90O angle. It is capable to eliminate the fluctuations of the fluid flow so it is used in pulsating applications where fluid flow varies frequently.

5. Y-type Globe valve

The problem of high pressure-drop in the Z-type valve is resolved in this valve. Here, instead of perpendicular angles in the flow path, we have 45O angles which reduce the pressure-drop drastically.

Advantages of Globe Valves

- Have throttling feature

- Opening and closing is fast compare to the gate valve

- It is fast-acting

Disadvantages of Globe Valves

- Not good for clean or sterile applications

- Very high pressure drop

- Noisy in high-pressure applications