Galvanometer – Types, Parts, Working Principle, Construction, Function, Applications, Advantages, Disadvantages

Introduction

If the switch is on the off mode in any electrical or electronic circuit, it is quite tedious to tell whether the current is flowing or not. As a result, a galvanometer is used to determine the current flow in the circuit. These are electromechanical devices that are used to not only detect current flow but also to measure current within a circuit or conductor. This instrument can also be transformed into an ammeter with a slight change in the settings.

The primary capacity of a galvanometer is to change over electrical energy into mechanical energy i.e., the flow providing inside the attractive field gets changed into attractive force. The galvanometer gadget is found to work like an actuator as it is responsible for creating a pivoting force that turns to the side inside the converse bearing.

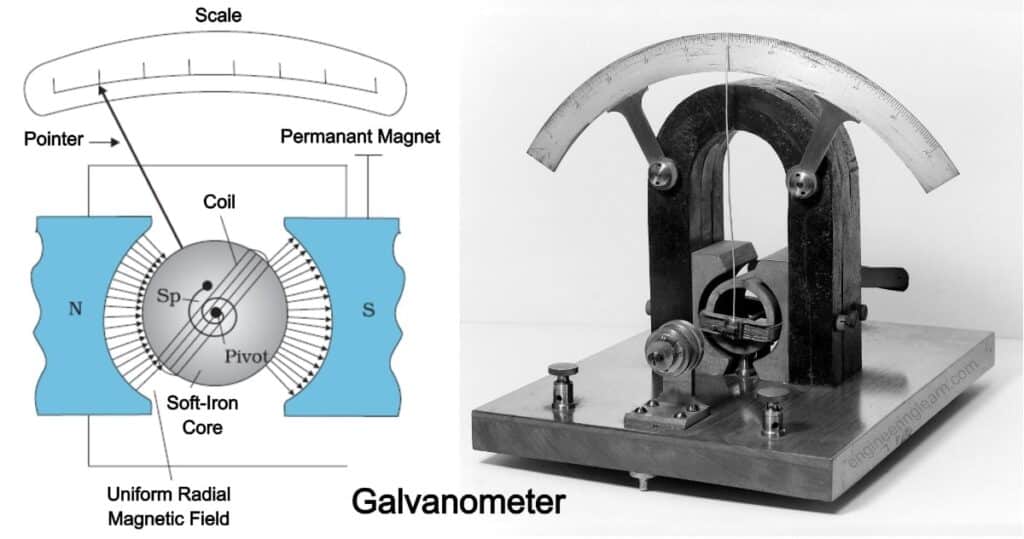

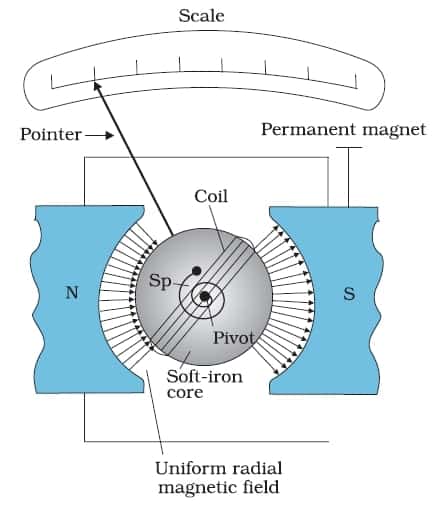

A soft iron cylinder is contained through a frame wherever a coil is covered on the frame, and a permanent magnet or magnet of the cylinder head is positioned in the region of the frame in the construction of a galvanometer. In the spindle form, there is an axial rod and pivot. The main purpose of a magnetic needle or indicator is to specify the readings on top of a scale. The readings on the scale are in amperes, or A.

Construction of Galvanometer

The working of the galvanometer is, in a current-conveying loop, the current streaming is in a stable attractive field thus, the attractive needle in any case pointer gets goes aside to note down the estimation. The fundamental pieces of the galvanometer incorporate the accompanying.

1. Moving Coil

In the galvanometer, the current-conveying part is a moving loop. The state of this curl is a roundabout or rectangular shape. This curl incorporates the quantity of copper wire turns. The curl moves openly in the upward pivot of balance in the middle of long-lasting magnet shafts. The iron center gives the way for less hesitance transition to give a solid attractive field fundamentally for the loop to move unreservedly.

2. Suspension

The curl in the galvanometer can be adjusted through a level lace that holds the current and supplies to the loop. The other loop is the lower suspension where the force impact of this is little. The material used to make a higher suspension loop is copper or gold wire in strip structure. You must know that the mechanical tolerance of the wire is not that good. Therefore, the galvanometer needs to be taken care with no heavy jerks at it.

3. Torsion Head

The twist head in the galvanometer is for the most part used to control the area of the loop and for managing the setting to nothing.

4. Mirror

The suspension supports a small mirror that emits a light ray, which is put on the scale to measure the deflection.

Working Principle of Galvanometer

The galvanometer’s primary function is to determine the presence, direction, and strength of an electric current in a conductor. This is based on the principle of energy conversion from electrical to mechanical.

A magnetic torque can be felt when current is supplied in a magnetic field. It turns by an angle proportional to the flow of current through it if it is open to turning below a regulating torque. This is a type of ammeter that is used to detect and measure electrical current.

At the point when a galvanometer is united to a circuit, then the progression of current will be there in the loop. As the curl is deferred inside an attractive field, then an avoiding force works upon it. On account of this force, a curl in the galvanometer will begin spinning from its place.

When the coil rotates, the control springs are twisted, causing a stretchy restoring torque to develop within them, which then resists the coil spinning.

As the re-establishing force transforms into comparable to the avoiding force, then the loop unwinds in a steady position. A galvanometer is frequently used in many electrical circuits to detect flow and in investigations to identify the invalid point.

When a significant current passes through the galvanometer’s coil, the pointer may strike the stop pin due to the large deflection. As a result of the intense heat generated, the coil in the galvanometer may catch fire.

It is important to note that these can be safeguarded from any type of potential damages by simply utilizing a wider portion of the wire in any case by associating a copper strip in corresponding to the curls which is probably known as a shunt. When contrasted with the curl’s obstruction, its opposition is tiny. Consequently, the majority of the current stream supplies through the shunt and some measure of current provided through the curl. In this manner, there is zero chance of damage to the loop.

Parts of Galvanometer

There are various examples of galvanometer which are as follows:

Tangent, Astatic, Mirror, and Ballistic galvanometers are found to be of different types of galvanometers. However, D’Arsonval, moving coil, and Weston galvanometers are increasingly commonly utilised. It is critical to know that the ancient name of an electric current detector with reference to a moving coil was galvanometer.

Some more galvanometer includes the following.

- Kelvin Astatic

- Ballistic

- Horizontal

- Pouillet tangent

- Pye Coulomb Balance

- Latimer Clark Differential

- Einthoven String

- Iron Vane

- Primarily used for lectures

- Universal Tangent

- Kohlrausch

- Brass Cylindrical

- Scientology E-meter

- Mirror

World’s Largest Galvanometer at Cornell

Galvanometers can be classified into two types based on their applications: Ballistic and Dead beat/a periodic. The periodic type is used to measure and detect the potential difference and charge within the circuit, whereas the ballistic type is used to detect and measure the charge.

Galvanometers are classifies into two different types which is based on their construction: moving coil and moving magnet. Moving coils are found being classified into two different types: first can be a pivoted moving coil and the other one can be a suspended moving coil, whereas moving magnets are found to be the ones which are separated into two different types: pivoted moving magnets and suspended moving magnets.

Types of Galvanometer

1. Tangent Galvanometer: ( Types of Galvanometer )

A tangent galvanometer is referred to as that galvanometer which is an early estimating instrument that is utilized for the purpose of estimating the electric flow. It works by utilizing a compass needle to analyze an attractive field produced by the obscure current to the attractive field of the Earth.

2. Mirror Galvanometer: ( Types of Galvanometer )

An ammeter that demonstrates it has detected an electric flow by redirecting a light pillar with a mirror. The light emission projected on a scale goes about as a long massless pointer. In 1826, Johann Christian Poggendorff fostered the mirror galvanometer for identifying electric flows. The device is otherwise called a spot galvanometer after the spot of light created in certain models. Reflect galvanometers are referred to as the ones which were utilized widely specifically in the logical instruments which were found not to be dependable or stable electronic intensifiers that were found to be quite accessible. The most widely recognized utilizes were as recording gear for seismometers and submarine links utilized for telecommunication.

3. Ballistic Galvanometer: ( Types of Galvanometer )

A ballistic galvanometer is a kind of touchy galvanometer; generally a mirror galvanometer. This does not seem to be that similar to a current-estimating galvanometer, as the moving part is found having a huge snapshot of the dormancy wherein this manner gives it a long wavering period. It is actually an integrator estimating the amount of charge released through it. This may be both of the moving loop as well as moving magnet type. Ballistic galvanometer alignment arrangement. Grassot fluxmeter, a type of ballistic galvanometer. Grassot fluxmeter alignment course of action utilizing a standard common inductor and a known amount of electrical release. Estimating arrangement is comparative.

This is normally finished by interfacing with the galvanometer a known capacitor, charged to a known voltage, and recording the redirection. The steady K is determined from the capacitance C, the voltage V and the redirection d: {\displaystyle K=CV/d}K=CV/d where K is communicated in coulombs per centimeter.

4. D’arsonval Galvanometer: ( Types of Galvanometer )

It is referred to as that galvanometer which is found having a moving-coil galvanometer accompanied with a filament suspension or a pivot and hairspring that regularly spins within the poles of a powerful permanent magnet around a stationary soft-iron core.

5. Moving Coil Galvanometer: ( Types of Galvanometer )

A moving coil galvanometer is a device that measures electrical currents. These types of moving coil galvanometer are referred to as sensitive electromagnetic gadget that are only capable of detecting the extremely low currents varying up to few microamperes. These are the galvanometers which are most commonly found being classifies into two different types:

i. Suspended coil galvanometer

ii. Pivoted-coil or Weston galvanometer

Moving Coil Galvanometer Principle

A current-conveying loop when put in an outside attractive field encounters attractive force. The point through which the loop is diverted because of the impact of the attractive force is relative to the greatness of current in the curl.

6. Astatic Galvanometer: ( Types of Galvanometer )

A galvanometer having two needles with inverse polarities that diminish the impact of the world’s attraction

How to Make Simple Galvanometer at Home

Laser pointers, projectors, and laser shows are all possible using galvanometer equipment. Galvo systems are moving mirrors that allow performers, laser lights, and music to be combined. The following are the components needed to create a DIY galvanometer.

• Compass made with insulated copper wire

• Battery Type D

• Scissors/Wire Cutters

• Measuring tape/ruler

Galvanometers are used primarily to detect electrical currents. So we’ll need a copper wire, a compass, a power supply, and a thin insulated wire that’s 3 to 4 feet long to build our DIY instrument. An inch of plastic insulation must be removed from each end of the copper wire to expose bare copper wire.

Presently cover the wire roughly around the compass. Cover the copper wire emphatically a few times and leave 8 crawls of wire at each end.

All the exposed finishes of the copper wire towards a cell battery along with a pass on the circuit continue for a duration of 2 to 3 seconds after which it can be observed that the needle begins to turn. The progression of current will warm the wires and battery assuming that we leave the circuit for few moments.

The progression of current all through the circuit will produce an electromagnetic field to make the compass needle polarized and the current supplies all through the circuit.

In the event that you change the progression of the current bearing, you can see a shift inside the course that the needle of the compass turns.

This DIY galvanometer is certainly not an exploratory evaluate of current and it shows you the progression of current and its bearing, with the exception of the number of amperes are being created.

From different sources, we can test the current. For example, append two zinc or copper terminals into half lemon piece and after that push one of the finish of the galvanometer to each cathode with wires.

Application of Galvanometer

The uses of the galvanometer incorporate the accompanying.

• These instruments are utilized for deciding the current inside the circuit

• By utilizing this, the voltage not entirely set in stone in the middle of two places

• This is utilized to decide the course of the current inventory as well as the invalid point.

• These are primarily utilized in laser etching, laser shows, control frameworks, laser sintering, laser TV, and so on

• By using this instrument regularly one can control the head servos status present inside the hard drivers, along with the DVD or CD players

• Prior galvanometers were utilized in telecom links to confirm on the off chance that there is a mistake, yet as of now, it is utilized in charge and situating designing because of its exactness and high accuracy.

• These are basically utilized in simple to advanced converters

• It is utilized to gauge the size of the gadget

• Galvanometers are utilized in the extensions and potentiometers to demonstrate the invalid redirection.

Advantages of Galvanometer

The benefits of a galvanometer incorporate the accompanying.

• Precise

• Solid

• These instruments are not impacted by the solid attractive field.

• It won’t change through a solid attractive field.

• The sizes of this instrument are uniform.

Disadvantages of Galvanometer

The following are some of the downsides of galvanometers:

• Overloading might destroy the galvanometer

• This instrument cannot be used to measure AC voltage.

• Once the temperature is altered, the restoring torque can be changed.

• Changing the torque is a difficult task.