What is Nut Buster? | How do Nut Busters Work?

Introduction

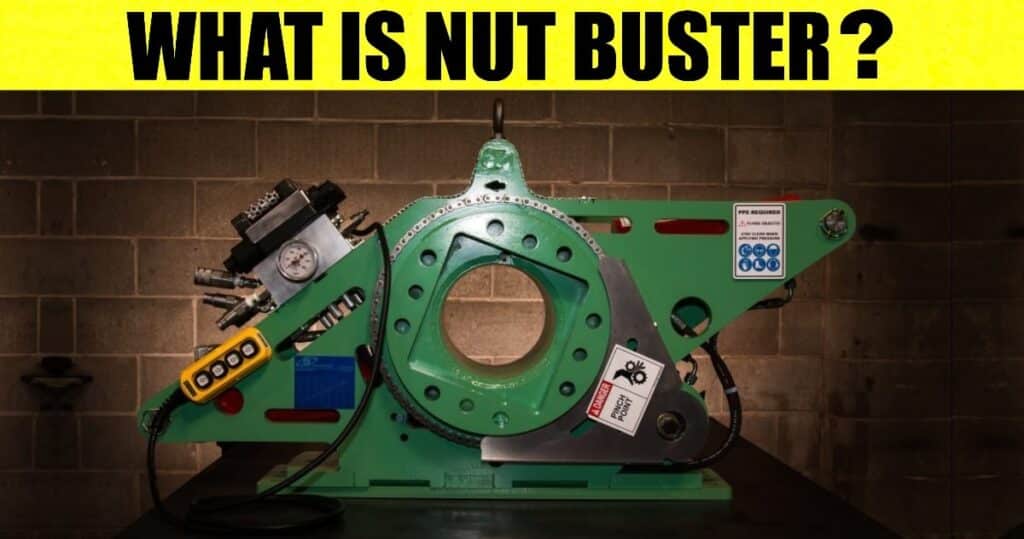

What is Nut Buster? | How do Nut Busters Work? – The Nut Busters is a hydraulic-operated ratchet (pressure-driven force wrench). The Nut Buster uses at least 2 GPM and 3000 psi to develop 20,000 to 100,000 foot-pounds of torque or force, contingent on the model.

What is Nut Buster?

The Nut Buster is a hydraulic-operated ratchet (water-powered torque wrench). It is a nut evacuation tool used to eliminate or install piston nuts and cylinder heads. The Nut Busters utilizes a square 8 plate as the base for the sockets and attachments. The attachment slide into the adapter or connector on one or the flip side of the Nut Busters and rotate 45° to lock in place. Contingent on which side of the Nut Busters is utilized the tool will rotate clockwise or counterclockwise. It can likewise be adapted to accommodate your existing table. You need to be sure or certain to read and grasp the operating instructions for the Nut Busters prior to operating the tool.

How do Nut Busters Work?

At the point when the wrench is placed on a nut or fastener and turned, there is a tension the other way that goes about as the clamping force pulling the bolted components in a similar direction with a definite tension. The joint integrity gives way to loosening or fastening the bolt, when the torque builds. How much torque is needed to fasten or loosen relies upon the length, size, and sort of joint, the quality of the fastener, and the lubricant utilized in it. Nut buster are designed in such a way that they fit different heights and widths of joints as well as their respective nuts. This offers simple and free movement without the obstruction of surrounding parts.

Below are some points which suggest how Nut Buster works: –

- Force is applied on the bolt utilizing a hydraulic tension device or the hydraulic(water-powered) stud bolt tensioner.

- This device comprises a high-pressure hydraulic cylinder and accessories that are viable with bolts and designed to fasten the grip.

- The measured water-powered(hydraulic) pressure that is applied, reaches out to the cylinder piston taking it against the puller that in turn pulls or stretches the bolt.

- When the applied force surpasses that of the preload tension of the bolt, and that which is required for its relaxation, it is rundown tightening it against the joint.

- If we talk about next stage, water-driven(hydraulic) pressure is released while keeping the latch from returning to its previous position by the tightened nut.

- The reaction member of a nut buster is its most dangerous or hazardous part. It adjoins against the stationery object stopping or preventing the wrench from turning the fastener around.

How to use Nut Buster for the Optimal Results?

There are specified ways in which a Nut buster should be utilized to keep up with safety and security. Like most advanced tools, Nut buster operates ideally when certain parameters are applied following security precautionary measures.

- Wearing Safety and security gear such as gloves and goggles is a must while working with a Nut buster.

- It is quite essential that you should wear a coat to give yourself a proper or legitimate cover that will deal with any jewelry or hanging objects.

- You actually should run the wrench no less than two times at the highest scale prior to applying it. This will assist you with deciding whether the moveable parts are running with their legitimate motion or movement and in the desired direction.

- Any Nut buster should be firmly or immovably held by its handle and not by the hose or aligned or adjusted connections.

- Make a point to get your hands far from the reaction bar or the boot.

- As you apply the torque, utilize a pulling motion, not pushing.

- You need to get rid of all cracked or worn sockets as they might break, damage the nut or result in more noteworthy debacles.

- You need to maintain a good distance and safeguard yourself in the event of an accidental break.

- Applying tension that surpasses calibrated range is an absolute no as it prompts instrument malfunction or breakdown as well as prone to accidents.

- Having your nut buster re-aligned something like once a year is vital and indispensable. In the event of a drop, make a point to re-calibrate it prior to utilizing it again.

Conclusion

The Nut buster is an element-rich stuff device. The wide rubber handle makes it simple to hold with a positive grip. The rubber or elastic handle similarly stops the metal from digging into your hand when you hit a stuck nut. This product can eliminate duplication frequently found in numerous maintenance shops. It is an excellent climbing penetrator and nut and bolt loosener. It doesn’t dry on a surface after a few days like different products. In this way, the surface doesn’t become fragile and stays lubricated and doesn’t flash rust, as different products cause when they dry up too early. Nut Buster eliminates rust and holds the surface from rusting.

Image Source: – hydraulitechs