Types of Rotary Valve: Application, Components, Limitations (Rotary Airlock Valve)

What is Rotary Valve?

Types of Rotary Valve: Application, Components, Limitations (Rotary Airlock Valve) :- The primary function of a rotary valve is to regulate the flow of material, generally to reduce the rate of flow to a desired flow rate. Rotary valves are also used in different engine designs. As a flat disc the rotary valve is used in two stroke motorcycle engines in which this arrangement prevent the reverse flow back into intake port in compression stroke.

Uses of Rotary Valves

Rotary valves are also used for metering the flow of granular bulks. It is also known as rotary feeder or rotary airlock. A hopper is used for feeding the material in valve and the valve rotor is used for handling and then the material is deposited in the conveyor system. Rotary valves are generally used in air conveyor system for the reduction of loss of pressure across valve, rotary valves is useful for metering the material at a controlled rate.

These valves lock and prevent the air loss while performing the important required material handling functions. Rotary valves can move sticky to dry materials and have various applications in plastic, food, pharmaceutical, chemical and manufacturing markets. There is minimum risk of product damage in the rotary valve, elimination of shearing effect completely cannot be done but in general 5 percent of material which is entering the rotary valve is subjected to the shearing effect between inlet throat and the rotor tip.

Operating Speed of Rotary Valve

Operational speed of a rotary valve is determined with respect to bulk density of the material and the size of the handled material because for high efficiency it is important to run the rotor at the correct speed.

Functions of Rotary Valves

- It is used for controlling materials flow rate to required rate.

- In inlet and outlet it maintains differential gas pressure.

- It act as a explosion or flame barrier

Applications of Rotary Valves

- Processing of food and chemical

- Batching, Mixing

- Feeding or discharging of pneumatic conveying lines

- Discharge of silos

- Plastic manufacturing

- Pharmaceutical manufacturing

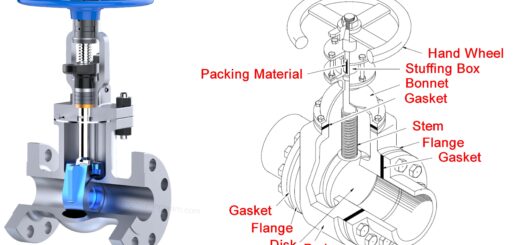

Components of Rotary Valve

1. Housing

It is generally of cast iron construction for reducing the cost and imparting rigidity. Housing provides a protective pathway and inlet/ outlet ports in valve.

2. Rotor

It is the rotating part of the valve provided for material handling.

3. Rotor Bearing and Seal

Rotor bearing is provided for holding the rotor in place and material is being sealed from inside of the valve housing through the bearing and the shaft seal.

4. Drive

Rotor shaft is attached with the drive mechanism from outside which control the rotation speed of the rotor and the direction of rotor.

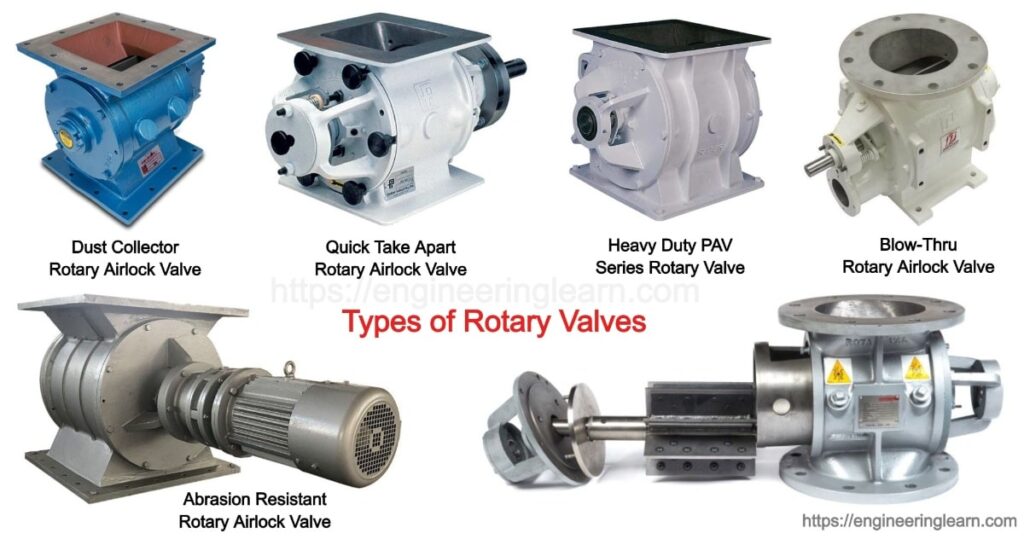

Types of Rotary Valves

With different functions there are some specific designs which enable the rotary valve to achieve the handling requirements. There are different types of rotary valves based on their applications.

1. BAV Rotary Airlock Valve: ( Types of Rotary Valves )

In material handling applications which require frequent cleaning, BAV Rotary Airlock valve is suitable for this purpose. It is designed with rotor which is demountable and rail system for safe removal of end plate and the rotor as a piece. This kind of a rotor have high efficiency by:

- Reducing the time by gapping rotor while reassembly.

- For quick reassembly it does self centering of the rotor.

- Prevents from operator strain and damaging of part from handling.

- For inspection, maintenance and cleaning the disassembling is fast and easy.

2. Dust Collector Rotary Airlock Valve: ( Types of Rotary Valves )

The dust collector series rotary airlock valves are ideal for the applications to use at the discharge of material of dust collectors, hoppers. These type of rotary valves are designed for low temperature minimal pressure differential applications. Dust collector series rotary airlock valves provide air seal and these does not feed at specific rate. They have heavy duty design with eight blade rotors, economical and precision machine.

3. Quick Take Apart Series Rotary Airlock Valve: ( Types of Rotary Valves )

As BAV Rotary Airlock valves is used for the applications which require quick and frequent cleaning or removal of rotary internal components, design of Quick Take Apart Series Rotary Airlock is done for increasing production efficiency by reducing the steps of gapping rotor at the time of reassembly which are time consuming. Cast iron or stainless steel is used for the construction of Quick Take Apart Series Rotary Airlock.

4. Heavy Duty PAV Series Rotary Valve: ( Types of Rotary Valves )

They are durable and rugged as the name indicate. Heavy duty PAV series are used for the displacement of free- flowing, dry powders from large bins to pneumatic system, it also maintain pressure differential. It can be constructed from cast iron or stainless steel. High duty PAV series rotary are used for the applications of high temperature. For handling the abrasive or corrosive material a coating of chrome, tungsten carbide is provided.

5. Blow-Thru Rotary Airlock Valve: ( Types of Rotary Valves )

The Blow – thru rotary airlock valves are specially manufactured and designed for the process which require discharge into pneumatic conveying line, these are well suitable for free – flowing materials. Huge volume results in lower speed operation of the rotor which decreases the wear and hence increase the efficiency. They have minimum air leakage, less maintenance and low pressure drop which results into high return on investment.

6. Abrasion Resistant Rotary Airlock Valve: ( Types of Rotary Valves )

Abrasion Resistant rotary airlock valves are used handling of very high corrosive or abrasive material. To withstand with abrasive and corrosive materials, ceramic lined cast iron housing is done. It is the most wear tear resistance and durable rotary valve among all types. For their precision tolerance it is lined and then honed.

Limitations of Rotary Valves

- It does not flow material, it just pass the material which fall into it.

- Generally rotary valves leak air when the system is being operated which results in poor performance of system.

- When the vent design is not done properly then it well reduce the system and valve performance.

- When the rotor speed is high then efficiency is very low.

- When the valve is being operated at high pressure, velocity erosion from fine abrasive material through clearance by leakage air.

Therefore, performance of a rotary valve can be affected by performance of a system. Valve size and its speed are selected with various factors like efficiency, throughput etc.

Image Source :- Rotolok, Praterindustries, Indiamart, Alibaba, Bulkinside