Types of Flooring and their Applications – (Complete Details with Picture)

Definition of Flooring

Types of Flooring (Floor) :- Floors are defined as the flat leveled surface which is provided in a building, in a structure for living purpose to step our foot on it and to store furniture and capable of supporting occupants in a building. Wood, stone, metal can be used as a material for flooring. They divide the buildings into different floors.

Floors above the plinth level (45cm to 60cm above the plinth level) is known as ground floor and above floors or floors at each storey above ground floor are called upper floors. The top most floor is known as terrace (It will be exposed to atmosphere, sun, wind, rain), storey constructed below the ground floor are basement (it is provided below the ground level).

Two Essential Components of floor:

1. Floor base: Lowest layer just above ground surface is compacted with moorum or sand fill. There is a second layer just above the floor base which is a sub floor of lean cement concrete or lime concrete which is given to provide rigidity.

2. Floor Covering or Flooring: Finally the floor finish is laid on the top of the sub floor which is known as floor covering.

Essential Requirements of the Floors:

- Adequate strength and stability

- Adequate fire resistance

- Sound insulation

- Damp resistance

- Thermal insulation

Factors Affecting Selection of flooring:

- Initial cost: Marble for residential building comes costly.

- Appearance: Pleasing appearance- desired color effect and architecture.

- Cleanliness: It can be easily cleaned, non- absorbent.

- Durability: Resistance to wear, temperature changes, decay with time hence long life is desirable.

- Sound insulation: Less or no noise when users walk on it.

- Thermal insulation: For comfort of users.

- Fire resistance: Upper floors require more safety.

- Smoothness: Should not be slippery.

- Hardness and maintenance.

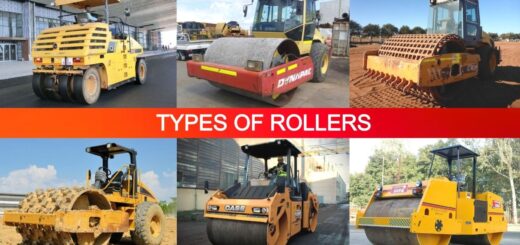

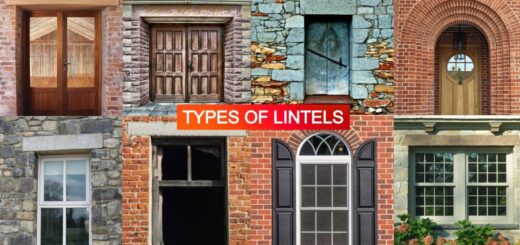

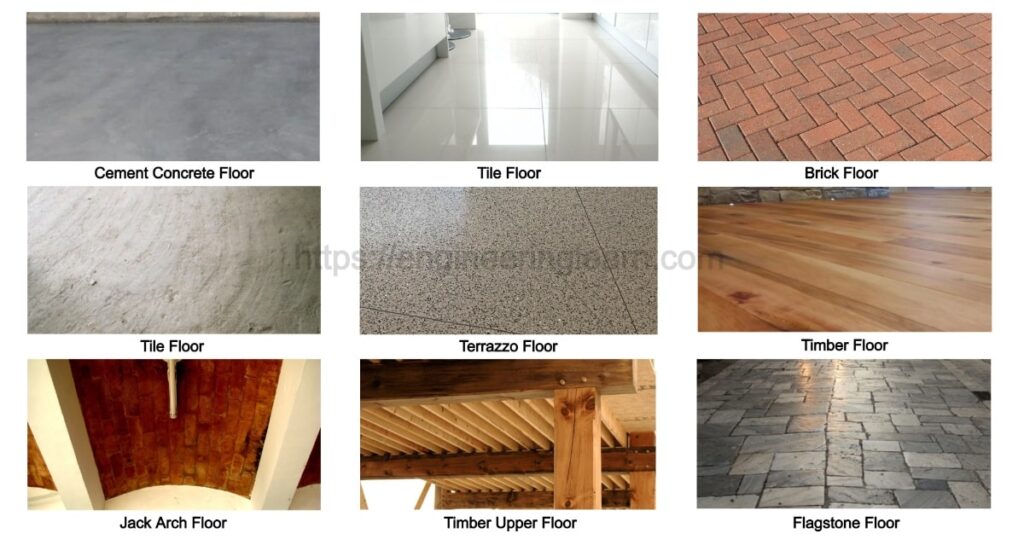

Types of Flooring ( Types of Floor )

A) Types of Ground Flooring

1. Cement Concrete Floor: ( Types of Flooring )

- It is one of the most commonly used type of flooring.

- There are three basic steps for the construction of cement concrete flooring

- Preparation of Sub- Base (which is common in all type of flooring)

- Laying of base concrete

- Laying of topping

- Flooring material used in cement concrete floor is cement and concrete.

- Cement concrete topping is made of 1: 2: 4 mixes; top surface is finished with trowels.

- Cured for 10 days.

- They are Non- absorbent, smooth surface and pleasing Appearance, Economical, Easily cleaned, hard, durable, fire resistance.

2. Tile Floor: ( Types of Flooring )

- In tile floor, tiles are used as toppings in floor.

- Tiles can be of any color, quality or shape.

- They are used for paving.

3. Brick Floor: ( Types of Flooring )

- In brick flooring, bricks are used as toppings of floor and well compacted earth filling is done under the floor.

- 10cm to 15cm thick layer of cement or lime concrete is laid over entire floor area for bonding are called sub- grade.

- Bricks laid on edge are on 12mm thick mortar bed such that all joints are full of mortar.

- If plastering is to be done, 12mm thickness can be provided after raking out the face joints

- This type of floor do not have smooth surface.

- They are hard and durable, Non- slippery, cheaper and easily repairable.

- They are commonly provided in go downs, warehouses, stores or in places where heavy articles are stored.

4. Flagstone Floor: ( Types of Flooring )

- In Flagstone flooring stone slabs are used as toppings in floor, thin slabs of lime- stones laid on concrete bedding.

- Size of stones- 30cm x 30cm, 45cm x 45cm and 60cm x 60cm.

Thickness- 2cm to 4cm. - For construction, earth surface is leveled, rammed and watered.

Layers of lime concrete of 10cm to 15cm thickness is laid and rammed properly.

Well dressed flagstones are laid and fixed with mortar. - They are used in godowns, stores, pavements etc.

- Slope of 1 in 40 is provided for drainage.

5. Mud Floor: ( Types of Flooring )

- In mud flooring, mud is used as toppings in floor and it is hard and fairly impervious.

- It used in a tropical country like India in village area.

- These types of floors are used in low cost construction and are easy in construction and maintenance.

- It maintains favorable temperature.

- Prepared bed- 25cm thick layer of select moist earth evenly spread out and rammed well to get consolidated thickness of 15cm. No water is used in ramming process.

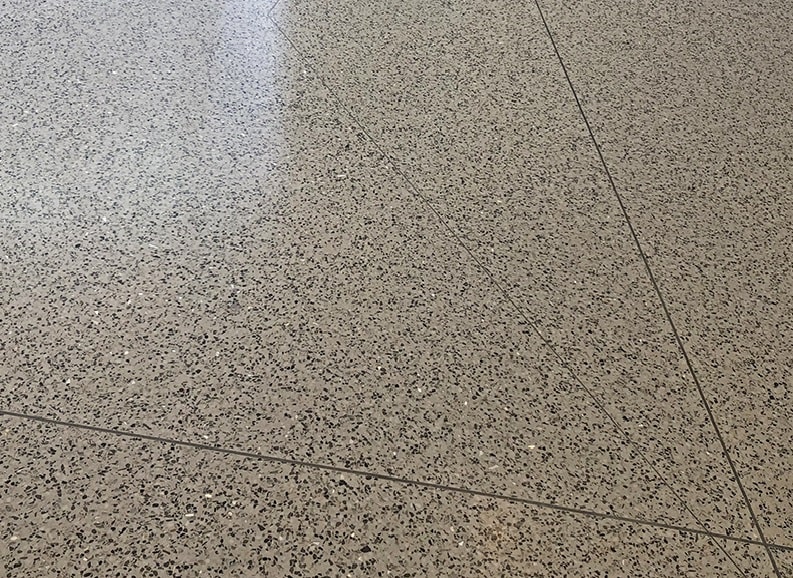

6. Terrazzo Flooring: ( Types of Flooring )

- Special type of concrete in which marble chips are used as aggregates, hence any desired color can be obtained by using marble chips of different size and shades.

- Used currently in residential buildings, offices, schools, hospitals etc.

- 40mm thick flooring is provided.

6mm thick terrazzo topping and 34mm thick under layer of cement concrete is provided.

- Before laying flooring, whole area is divided into suitable panels by using dividing strips.

- Terrazzo mixture: 1 part of cement (white or colored) and 2 to 3 parts of marble chips with water (should be workable mix).

7. Timber Flooring: ( Types of Flooring )

Timber flooring cab be of three types if it is provided in ground floor-

i) Wooden block flooring:

These type of flooring is preferred on ground floor when dampness is not a problem. Base concrete: 15cm to 20cm thickness, a layer of asphalt and timber blocks are laid on it.

ii) Wooden plank flooring:

Timber planks of 20mm to 25mm thickness and 150mm to 200mm width are used.

iii) Supported type timber flooring:

They are provided when loads coming are very heavy.

These are used in Gymnasiums, Auditoriums, Dancing hall etc.

B) Types of Upper Flooring

1. Flagstone Flooring on Steel Joist: ( Types of Flooring )

- These are cheap and easy form of floor construction.

- Width of room not greater than 3. 66m, rolled steel joists of small sections are placed at 30cm to45cm center to center along the width of room.

Flagstones should be 38mm thickness.

Light weight concrete, lime concrete or moorum or mud are used to fill the space above flagstone, so that consolidated thickness filling lies 13mm above flanges of joists. - Tiles of flagstone are laid above the filling and desired floor is achieved.

- Bitumen or paint coating is provided over steel joists to protect it from rusting when filling material is lime concrete.

- Steel beams span the width of room and spaced 2. 4m to 3m apart.

2. Timber Upper Flooring: ( Types of Flooring )

- Timber flooring is done in ground floor as well as for upper floor also, similarly all the other types of flooring can be done in upper flooring also but since our upper floor is going to carry huge amount of load as compared to ground floor.

- For upper floors, Timber floors are supported on rolled steel joists- Single joists, Double joists and framed timber flooring.

- They are the cheapest form of wooden floors and are most commonly used in residential type of buildings.

- Single joists: 25mm to 30mm thick planking are fixed to construct the floor which is known as bridging joists placed along the short span of the room and are fixed to timber wall plates.

Span for single floor is limited to 3. 66m.

Width of the joists is kept 5cm to 8cm wide and the depth is determined by the thumb rule: (4 x span in meters) + 5cm

If the span exceeds 2.5m, the timber joists are strengthened by providing herring bone strutting at the mid span by means of inclined piece of timber size 5cm x 3cm to 5cm x 5cm.

End wedge are provided between the wall and joist.

End of the joists are nailed to wall plates. If the adjacent joists are in the same direction, they are overlapped and nailed with each other. - For double joists: These are stronger and used for spans between 3.5m to 7.5m. Binders are the intermediate wooden supports on which bridging joists are supported.

Bridging joists are of smaller section because of intermediate support which is spaced at 30cm centers.

Spacing of binders should be between 2m to 3.5m and they rest on bearing templates made up of stone or wooden which should not be less than 0. 75m to 2. 5m in length.

3. Jack Arch Flooring: ( Types of Flooring )

- Jack arch is an arch made up of brick or concrete, supported on lower flange of mild steel joists. Joists are spaced at 1. 2m to 1. 5m center to center spacing and supported to their ends on the walls.

Rise of arch is kept 1/ 12th of the span.

Since super- imposed load is borne by the arch action, tension is developed at end span support and hence steel tie rods are provided.

Bottom of floor is not flat.

4. Jack Arch Flooring with Brick: ( Types of Flooring )

- In this flooring, centering is prepared using wooden board of 38mm thick segmental piece forming the soffit of the arch curve.

- End bricks are cut suitably of required shape to enable them to fit in the joists properly.

- To prevent rusting of rolled steel joists, cement concrete is filled around them instead lime mortar and entire work is kept wet for 1. Days.

NOTE: Only 1st class bricks, well secure the joists to supporting wall, 1.days curing, prevent rusting filling above arch only when curing is over.