Scroll Compressor: Definition, Working, Applications, Advantages, Disadvantages, Selection Criteria & Reliability

What is a Scroll Compressor?

Scroll Compressor: Definition, Working, Applications, Advantages, Disadvantages, Selection Criteria & Reliability :- Scroll compressors are also known as scroll pump, spiral compressor and scroll vacuum pump. Scroll compressor is defined as a device which is used for compressing the refrigerant or air. Scroll compressors are used as automobile supercharger in which it is called as scroll type supercharger, in air conditioning and as vacuum pump.

General Description of Scroll Compressor

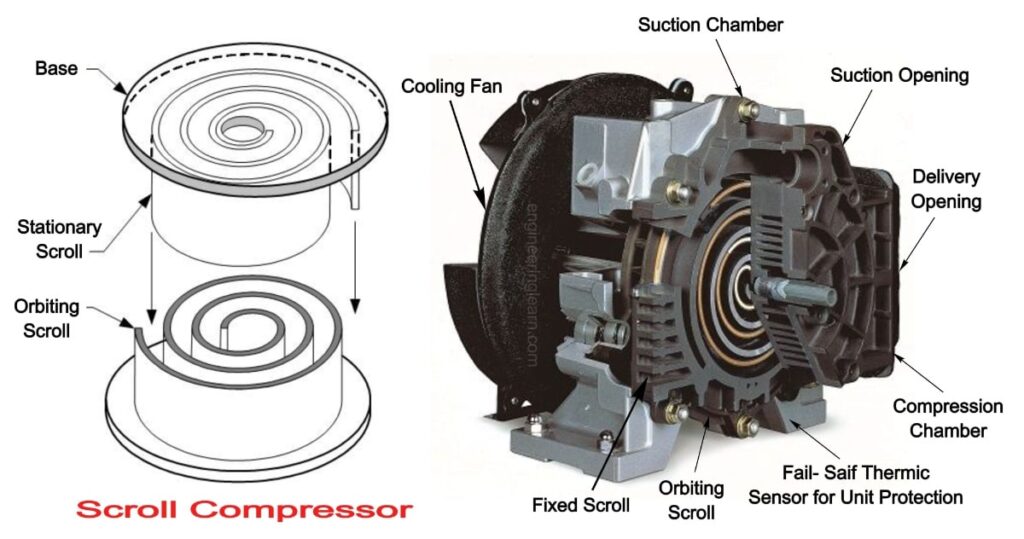

In a scroll compressors there are two inter-leaving scrolls which are used for pumping, compressing or pressurising the fluids like gases and liquid.

Generally, one scroll of the scroll compressor is fixed and the other scroll orbits eccentrically having no rotation, leading to trapping and compressing or pumping the fluids in between scrolls. Orbital motion can be provided by an eccentric shaft but the scroll should not be rotated. Another method used for the generation of compression motion is co – rotation of the scrolls in a motion which is synchronous with offset Centre of rotation. The relative motion should be same as in case when one is orbiting.

Leaks in the axial gaps can be prevented with the help of tip seals of spiral – shaped which is placed in the groove made on the tips in both spirals. These spiral – shaped seals can also help in lowering down friction. Once they are worn out, they are replaced with new ones.

In some scroll compressors, pressurised discharge gases are used for pushing both the scrolls together which completely reduce the requirement of tip seals and also enhance the sealing with use. This type of compressors are known as wear in at the place of wear out but the other parts like Oldham ring of the scroll compressor can wear out.

Significance of Scroll Compressor

Huge air conditioning systems, residential central heat pumps and some automotive air conditioning use scroll compressor in place of other reciprocating, rotary and wobble plate compressors. When a scroll compressor is operated in reverse then it is known as a scroll expander and it has the ability to produce mechanical work. Scroll compressors are generally more efficient as compared to other compressors.

Working of a Scroll Compressor

The scroll compressor has two spirals or scrolls in which one of them is moving while the other is attached or fixed with the body of the compressor. The first spiral rotates in a well defined path by the mating attached scroll. The rotating scroll is connected with the crankshaft of the compressor.

When the scroll rotates, the gas pockets are generated in between two scrolls. In outer part of scroll, the gas is sucked by the pocket and after that it is moved to the Centre of scroll. At that place compressed gas is discharged. When the gas moves in small internal pockets continuously then both its pressure and temperature starts to rise. Therefore desired discharge pressure is obtained with the motion of scrolls of the compressors.

Reliability of a Scroll Compressor

In any scroll compressor there are very less moving parts as compared to reciprocating type compressors. This eventually results in increasing the reliability of a scroll compressor. The manufacturers of Copeland scroll compressors, Emerson climate technologies stated that scroll compressors have 70 percent less moving parts as compared to various reciprocating compressors.

In 2006 Stoelting, manufacturers of equipment’s used in food services changed their design of a machine of soft serve ice cream from reciprocating compressor to scroll compressor. Thus they were successful in obtaining a result in which they discovered that the design in which scroll compressors were involved achieved higher energy efficiency in operation and also had better reliability.

Size of Scroll Compressor

Scroll compressor run smoothly and they have an added advantage of compact size. Therefore they do not need spring suspension. This results into small shell enclosures and reduced cost. This also results in small free volume but it reduces its liquid handling efficiency. Quite operation and small size of the scroll compressor enable the unit for building in high power density computers.

These compressors are also used for simplifying the design of piping because they do not need external connection for the purpose of primary coolant.

Structure of a Scroll Compressors

The structure f the scroll compressor are completely hermetic which means it is enclosed in the shell of the compressor and the shell of the compressor are cylindrical welded steel shell. Scroll compressor mainly used in HVAC services and refrigeration are in vertical in orientation in which the scroll sets are at the upper part of motor shaft.

Selection Criterion of Scroll Compressors

While selecting scroll compressors we generally consider two main factors, they are:

- Available electricity connection: We can choose a 3 – phase motor or single phase motor for compressor

- For better efficiency: The efficiency 3 – phase motor is better.

After that flow rate parameters as well as the differential pressure are taken into consideration. There are different kinds of scroll compressors easily available possessing various combinations of flow rate values and differential pressure. The selection of scroll compressor is done on the basis of requirement of particular flow rate and differential pressure.

After that some secondary parameters are taken into consideration such as noise level, the place at which the scroll compressor is going to be installed is finally decided. For example, if the scroll compressor is going to be used for residential air conditioner then the compressor used should be of lower noise level.

Applications of Scroll Compressor

- Scroll compressors are extensively used in vacuum pumps.

- They also find application in truck transportation.

- They are used in residential as well as marine containers.

- They find massive applications in commercial air conditioning applications.

- They are employed as super chargers in automobile applications.

- Scroll compressors are also used for fruit and food refrigeration.

Advantages of Scroll Compressors

1. Footprint and Weight

The footprint and weight of the scroll compressor is generally smaller than other types of compressors available nowadays.

2. Reduced Energy Costs

Scroll compressors have reduced energy costs because piston is absent in gas compression. This makes the scroll compressor achieve 100 percent volumetric efficiency.

3. Pulsating Effect of Gases

Pulsating of gas is also reduced. If gas pulsation is not completely eliminated then scroll compressors are operated with less vibration.

4. Operations Making Least Noise

The operation of scroll compressor is quieter because of the absence of few moving parts which create noise. The scroll compressor generally produce almost 5 decibel to 15 decibel less noise in comparison with other compressors like reciprocating one.

5. No Spring Suspensions Required

Due to less noise and vibration, there is no requirement of spring suspensions.

6. Lesser Moving Parts

Scroll compressors have les moving parts which results in less vibration as well as lower vibration which leads them to be more durable.

7. Simpler Design

The design of scroll compressors is simple and small because they do not have few moving parts.

8. Hundred Percent Volumetric Efficiency

The nonexistence of pistons for gas compression facilitates scroll compressors to attain 100% volumetric efficiency.

9. Reduced Re-Expansion and Valve Losses

In reciprocating compressors there are unwanted re-expansion losses in each piston stroke. However in scroll compressors such losses are eliminated. Also the, valve (ports) losses are eradicated because of the removal of suction and discharge valves.

Disadvantages of Scroll Compressor

- No easy repairs: One of the major disadvantages is that the scroll compressors are not easily repairable. Also they cannot be easily disassembled for maintenance.

- No rotation in both directions: Generally the reciprocating compressor can be rotated in both direction but the scroll compressors cannot be rotated in both the direction.

- Increased capacity control: Capacity control of the system is increased in few scroll compressors which results in some problem.

- Lower capacity: They have low capacity.

- Expensive in market: Scroll compressors are relatively expensive.

- Increased air temperature: The compressed air in scroll compressor get very hot as compared with other compressors.

Image Source :- theworkshopcompressor, pneumatictips