Operation of Milling Machine

Operation of Milling Machine:- Milling machine is device that is used to remove material from the workpiece by feeding the workpiece past a rotating device called milling machine.

Principle of Milling Machine

- Workpiece is clamped on the worktable.

- Milling cutter is mounted on to the arbor or spindle of the machine.

- Milling machine operation at high speed with feed to be fed against the worktable in rotating milling machine in X, Y ,Z directions.

- Milling cutter is made up of material harder than the workpiece table.

Classification of Milling Machine

Knee & column type: Horizontal, vertical, universal & turret. These all machines are equipped with wide range of flexibility inside the operation.

Production type: simple, duplex, Triplex suitable for very large production of similar Component with less flexibility than earlier described.

Plano miller: Suitable for large production workpiece.

Special purpose type: suitable for gear profiling, spline shaft manufacturing i.e. keyway milling & spline shaft milling.

Features of the Milling Operation

- Interrupted milling: Material is removed for the rotating part of the milling machine due to this, cutting edge gets time to cool before its remove material again thus milling operation is cooler than the turning operation.

- Large material removal: from the construction the chip size is small but multiple edges arrangement provides high material removal in comparison with turning operation.

- Variation in chip thickness: Basically there is cyclic variation in chip thickness from zero to maximum that gives two disadvantage that is harmful for surface finish & Tool life.

Components of Milling Machine

- Base: lower part of the machine that arrangement is to provide support to the system.

- Column: Vertical part fixed on to the machine.

- Knee: that is elevating screw which moves it up & down.

- Saddle: mounted on the knee to support & provide the cross feed mechanism to the worktable.

- Spindle: Hollow shaft driven by motor to rotate milling cutter.

- Arbor: In horizontal milling to hold & rotate milling cutter.

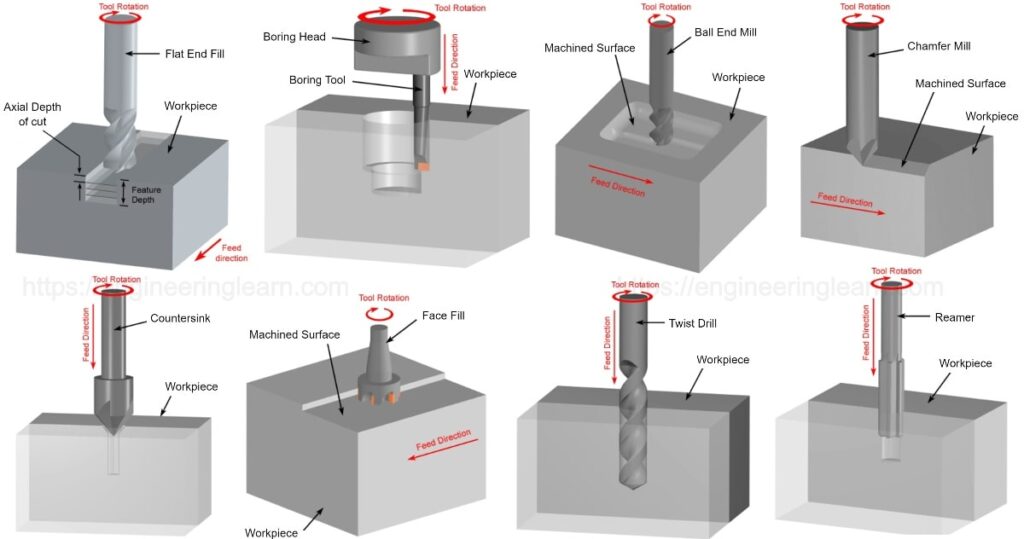

Types of Performed in Milling Machine

1. Plain Milling (Up & Down milling)

Machining is done by teeth on to the cylindrical surface of cutter finished surface is parallel to the axis of the cutter.

2. Face Milling

Machining is done by the teeth this time on the flat surface of the cutter, while finished surface is perpendicular to the axis of the cutter.

3. Side & Face Milling

Machining is done by teeth on the cylindrical surface as well as flat surface, finished surface are perpendicular as well as parallel to axis of the cutter.

4. Gang Milling

Gang milling operation more than one milling cutters are used to machining. It is a horizontal milling operation system, this more than one cutter with different shape and sizes are fixed at the arbor, which cut the desire shape in one pass. This milling operation can save mostly of time of milling.

5. Cam Milling

Cam milling is the operation of production of cams in a milling machine by the use of a universal dividing head and a vertical milling attachment. The axis of the cam can be set from zero to 90 degrees in reference to the surface of the table for obtaining different rise of the cam. The cams are mostly used to open and close of valves in the internal combustion engines.

Image Source :- custompartnet