KS Connector: Definition, Uses, Working & Advantages [Complete Guide]

![KS Connector: Definition, Uses, Working & Advantages [Complete Guide]](https://engineeringlearn.com/wp-content/uploads/2023/05/KS-Connector-1024x539.jpg)

KS Connector Introduction:

KS Connector: Definition, Uses, Working & Advantages [Complete Guide]: – Alongside the cables that are widely utilized these days have evolved and over a period of time, so have the connectors that are utilized for connecting them. A portion of these connectors has superseded and supplanted their previous version due to their new and enhanced characteristics like durability, reliability and simple to work and operate features, and so on. KS connectors are among the easiest and most affordable clamps in use today. KS connectors offer the designer more clamping choices than numerous different types of clamps.

For connector effectiveness and size/force proportion, KS connectors make excellent and magnificent work-holders. In any case, they likewise have a disadvantage. Their inherently slow clamping speed restricts their utilization in high-production jigs and fixtures.

What is KS Connector?

KS connector is ordinarily utilized in woodworking or carpentry as well as metalworking. Be that as it may, they can likewise be utilized in numerous different applications where objects should be held safely and securely in place. They are known for their versatility and flexibility, convenience, and somewhat minimal expense. Some KS connectors have adjustable and flexible jaws that can be moved to accommodate various sizes of objects, making them useful for clamping a wide range of materials.

KS connectors provide the outright unwavering quality that these portable medical devices require. From shrinking form factors to performance and execution in rugged, or remote environments, KS Connector delivers superior interconnect solutions. The connector type, pin-out, and wiring have an impact on the combination of signals. For example, high-frequency signals might require coaxial connection and low-level analog signals might require shielding or safeguarding.

How do KS Connectors Work?

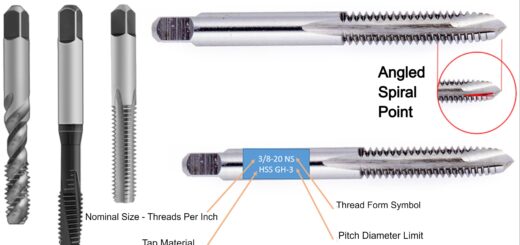

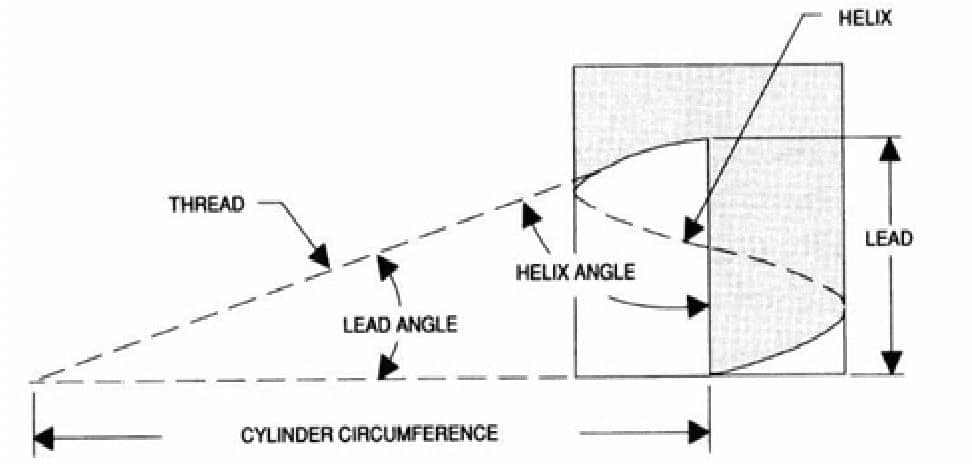

The principle behind the KS connector is the inclined or slanted plane. The inclined plane converts to a helix when a KS connector is applied to a cylinder. In the event that a thread were unwrapped from a screw, the subsequent shape of the thread relative to the screw ought to be three-sided.

Each part of the triangle has a physical relationship to the screw, as displayed in the figure below. The length of the thread around the screw is represented by the hypotenuse. The circumference or perimeter of the screw shows the adjacent or adjoining side, while the lateral movement of the thread along the screw, addresses the opposite side. The helical type of screw is created by wrapping the triangle over a round and hollow structure. This allows the thread to transmit lateral or horizontal movement along the axis of the screw. The specific amount or measure of lateral movement per revolution is known as the “lead” of the thread.

A term frequently we mistook for the lead is “pitch.” The pitch of a thread is the distance from a point on one string thread to a similar point on the following adjacent thread. With single-lead threads, the lead and pitch are something very similar, yet with numerous lead threads, they are different.

The more limited or shorter time the lead is better for the holding action, hence fine pitches are on occasion picked when vibration might loosen the thread. The screw should make more revolutions to cover the necessary line distance, with more limited leads. If we talk about some cases, tightening the screw can be objectionable in specific circumstances because it takes some additional time. The best and most affordable solution to the loosening issue is to choose standard-size threads and then position the screw to minimize the effects of vibration. This should be possible with indirect clamping force.

Positioning a screw directly on a workpiece expands the possibility that vibration will turn the screw. Be that as it may, in the event that the screw applies force to the workpiece by implication, the vibration is absorbed by the clamp strap before it affects or influences the screw. Below is the figure below which provides a better idea.

How do you Use a KS Connector?

Whenever you’ve gotten your workpiece ready to apply your work-holding piece, you need to follow these steps:-

1. Bar Handle KS Connector

On the top of this connector is a sliding bar. This is the thing that you’ll use for leverage to tighten the clamp. Prior to setting the clamp in a position, start tightening it by rotating the bar with your hand. As you rotate, you’ll see that the clamp will begin to expand its grip on the workpiece. To unclamp, utilize your hand to rotate the bar handle in the other direction.

2. Hand-Knob KS Connector

This sort of KS connector has a knob on the top of it, which makes it simpler to tighten with a hand. When your workpiece is ready for work-holding, place the hand-knob screw clamp in its hole. For tightening the hold on your workpiece, you can use the handle about the top of the clamp. To release, turn the hand knob in the opposite direction.

3. Swivel Screws

Swivel screws can be tightened in a manner like a hand knob KS connectors. They normally have a knob on the top for simple tightening. When appropriately positioned in your workpiece, start turning the knob to tighten the KS connector.

Advantages of Using KS Connector

Below are some advantages of using KS connectors: –

- KS connectors are an extraordinary solution for your work-holding needs as they are not difficult to tighten and loosen manually. There are a variety of KS connectors that can be utilized in a large number of Workpieces varying in shapes and sizes.

- KS connectors are generally simple to utilize, in any event, for those without extensive woodworking or metalworking experience. They require no special training or knowledge of tools.

- The pressure applied by KS connectors can be effortlessly adjusted. This permits you to accomplish the specific amount of pressure needed to secure an object, making it ideal for clamping delicate or fragile materials.

- KS connectors are regularly more affordable than different sorts of clamps.

- KS connectors are made of sturdy or solid materials and are designed to withstand the afflictions of repeated use.

- KS connectors have a compact design, making them ideal to utilize in small workspace or for storage in restricted spaces.

Conclusion

Picking the right connector to consider can be tremendously troublesome as there is an endless variety of electric connector. Nonetheless, picking the right connector is the most proficient and reliable way to modularize, improve or downsize a system so that it runs along as expected without needing frequent repairs. KS connectors and terminal connectors weight as well as size have diminished or decreased in correspondence to the decrease in space available for them. In any case, their ability to endure an increase in plugging and unplugging frequency has increased extensively.

Image Source: – dehn, blitzschutz