Inside Micrometer: Definition, Types, Working, Uses, Least Count, Advantages & Disadvantages

What is Inside Micrometer?

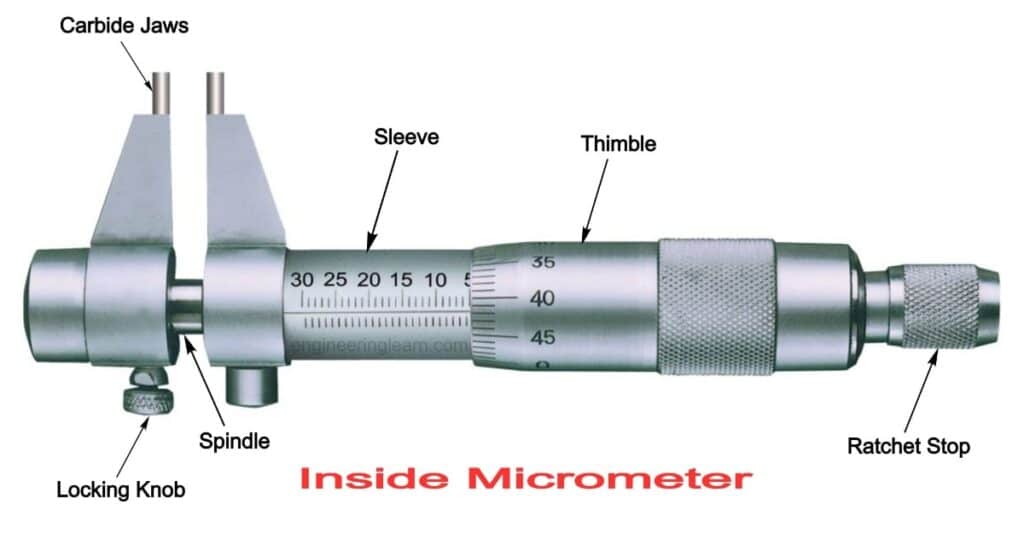

Inside Micrometer: Definition, Types, Working, Uses, Least Count, Advantages & Disadvantages :- Inside micrometer is used for the measurement of large internal diameter. They can measure the inside diameter of registers and holes. They look like pen and in middle there is a thimble which turns. Whenever the thimble turns then micrometer expands. The thimble will expand till end of each tool are able to touch inside the pipe and then numbering system are used for finding the measurement on thimble.

For inside micrometer, steel of good quality is used in spindle and the measuring head and for face tool of high grade steel are used.

General Description of Inside Micrometer

In general, the inside micrometer consist of micrometer unit or a measuring head, spacing collar or spacer, a handle and extension rods. In the measuring head of inside micrometer comprises a thimble which holds the reading to 50mm which is known as thimble division reading and it have only one way marking.

The barrel or sleeve has index scale or main scale as well as the sub scales in which two ways marking are provided. Main scale can provide the measurement up to 25 mm whereas the measured value is called the main scale division. The measuring head’s frontier end are also called as anvil there is a hole by which extension rods can be inserted in the inside micrometer. There is a locking screw provided to one side of anvil which is used for adjusting extension rods and they helps to hold the extension rod firm and in other side a hole is provided which is used for fitting the handle, the handle are used for the insertion in inside micrometer. At the posterior end have screw which is used for the adjustment of the thimble.

Types of Inside Micrometer

There are different types of micrometer which is available for the use of specific purpose and inside micrometer is one such type of micrometer and they can used for measuring inside diameter of bonded wall objects such as hollow pipe or cylindrical pipe.

Inside micrometers are of two types:

- Analog type inside micrometer

- Digital type inside micrometer

Least Count of Inside Micrometer

For analog type of micrometer, the least count is 0. 01 mm and for digital type of micrometer, the least count is 0. 001 mm. The least count of the micrometer is measured in inches or millimetre and provides precise readings. There are various types of inside micrometers which is available in several of sizes as well as in designs.

Range of an Inside Micrometer

Different sizes of extension rods are available which range between 50 mm to 200 mm which depends on requirement.

Classification of extension rods are:

- 50 mm to 75 mm

- 75 mm to 100 mm

- 100 mm to 125 mm

- 125 mm to 150 mm

- 150 mm to 175 mm

- 175 mm to 200 mm

Extension rods are usually used for the objects which are extensive and have large diameters, and extension rods are used with spacer, spacer are of 12mm and they can be used for small diameter with measuring head.

Working of Inside Micrometer

Measurement of inner diameter by inside micrometer:

In the design of the inside micrometer, they have jaws where one of the end are movable whereas the other end is fixed. Their working are very simple and the working of inside micrometer have three steps:

- Fixing of the rod and the spacer.

- Adjustment of the screw

- Measuring

Advantages

- Provide accurate measurement.

- They have integrated scale.

- They are durable and long lasting.

Disadvantages

- They have limited range.

Image Source :- weprotool