Gate Valve (Wedge Valve): Types, Parts, Working, Uses, Advantages & Disadvantages

What is a Gate Valve?

Gate Valve (Wedge Valve): Types, Parts, Working, Uses, Advantages & Disadvantages : Gate Valves that are sometimes referred as wedge valves are taken in use to chop off/restrict the flow of fluid with the assistance of rectangular gate also known as Gate that is inserted into the flowing fluid path. Gate valves don’t need immense variety of areas on the axis of the pipe and hardly cause any restriction to the flow of fluid once the gate is ready to be absolutely opened aiding wedge valves to possess flow with terribly bit of pressure drop.

Wedge valves are most generally taken in use with significantly larger pipe diameters (ranging from 2″ to the larger pipes) as a result of they are less complicated to make than kind of the opposite sorts of valves in larger sizes. However, in recent times, the larger sizes are being slowly replaced by butterfly valves attributable to the area limitations underneath that they are setup.

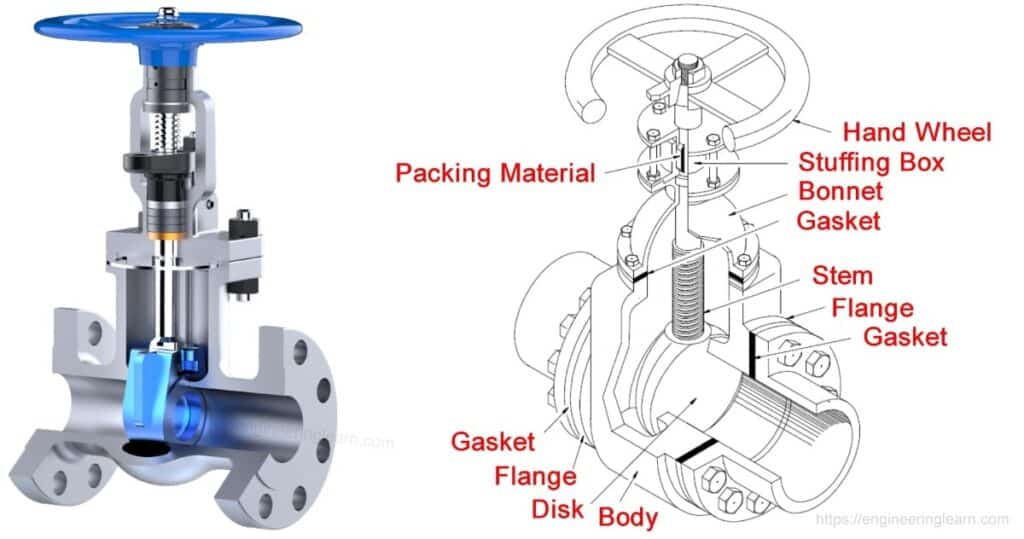

Parts of Gate Valve

Gate valves are made from 3 major components: bonnet, body, and trim. The body does have an affiliation to the piping by means that of screwed, flanged, or welded connections. The bonnet, that contains the moving elements, is joined to the body, typically with the assistance of bolts, to permit simple improvement and maintenance processes. The valve trim contains the stem, the wedge, the gate, or disc, and additionally the seat rings.

Working of Gate Valve

The main operation mechanism of the wedge valve is extremely easy. They are thought-about to be multi-turn valves as a result of it invariably takes quite one full spherical flip of 360° so as to absolutely close/open the valve. Once the gate is raised removed from the path of the flow, the valve gets opened and once it returns to its initial position (closed), it seals the bore that finally finishes up in nursing an extreme full closure of the valve.

Types of Gate Valves

1. Parallel Disk Gate Valve: ( Types of Gate Valves )

Parallel gate valves embody a parallel moon-faced gate like closing instrumentation. This closing member could have either one disc or twin discs with a mechanism spreading in between. The force that exerts pressure on the disc against the seat is taken management of by the fluid pressure that acts on either a floating seat or a floating disc.

2. Conventional Parallel Gate Valve: ( Types of Gate Valves )

When we tend to contemplate a regular parallel slide wedge valve, in it the closure member contains 2 discs that in between consists of springs. The task of those springs is to stay the downstream and upstream in sloppy contact and to boost the load (seating) at low pressures of fluid. The disc is gift within the belt eye in such a fashion that it prohibits their spreading not being restrained as they still get into the absolutely open position of valve.

3. Through-Conduit Gate Valve: ( Types of Gate Valves )

Through-conduit gate valves square measure merely place as gates (one-unit) that embody a hole of bore size. In state of being open, the bore size hole is aligned with the 2 seat rings to make a sleek flow with as minimum turbulence as potential. This special style permits for minimum pressure loss on the system into thought and is totally acceptable for transportation of fuel liquids (NGLs) and oil.

4. Knife Gate Valve: ( Types of Gate Valves )

Knife Gate Valves are typically regarded as a special variety of wedge valve (parallel) and is meant advisedly throughout thanks to cope up with systems that have a significantly high content of suspension of solid materials in them.

5. Solid Taper Wedge Valve: ( Types of Gate Valves )

Solid or plain wedge is one altogether the foremost normally & wide used disk sorts inside the business due to its strength and ease. It will either be of solid or hollow body construction. This style so boasts of being rough and sturdy and easy, however distortions that square measure caused thanks to the valve body attributable to the pipeline and thermal stresses could reciprocally jam the metal sitting wedge or tend to unseat it creating it additional in peril of outflow.

6. Split Wedge Gate Valve: ( Types of Gate Valves )

Split wedge disk is created of 2 solid items and is command at the side of the assistance of specific mechanism like spring or a spacer ring. To stay the plates intact along, the body contains grooves throughout that the wedge assembly traverses. Split wedge is self-aligning and self-adjusting to each seats’ sides. Disk flexibility is complementary to the split wedge style. This flexibility permits the split wedge to simply seal.

7. Flexible Wedge Gate Valve: ( Types of Gate Valves )

The wedge is sufficiently versatile to search out its own orientation. As a result of the wedge is straightforward and contains no separate elements that might rattle loose in commission, this construction has become a favored style. This style improves seat alignment and offers higher leak tightness.

8. Rising Stem Gate Valve: ( Types of Gate Valves )

Rising stems are connected to the gate as they are fastened with it and they either rise above or get lower along when the valve under study is under operation, which hence provides us with an indication which is visible of the valve position and hence making it considerably easy to grease the stem. A nut rotates round the rib stem and moves it. This sort of valve tends to have a screwed stem system in it and henceforth the packing is leaded to wear as a result of the to-and-fro up and down movement and even turning of stem.

9. Non-Rising Stem Gate Valve: ( Types of Gate Valves )

Non-rising stems tend to have a rib into the gate, and rotate with the wedge within the valve while raising and lowering. Rotation of the wheel tends to operate the valve; however, the stem doesn’t start of the housing. They take up less vertical area since the stem is unbroken at intervals the valve body.

Uses of Gate Valve

Gate valves square measure usually used once minimum pressure loss and a free bore is required. Once totally open, a typical gate valve has no obstruction within the flow path leading to a really unaggressive loss, and this style makes it attainable to use a pipe-cleaning pig. A gate valve may be a multiturn valve suggests that means} that the operation of the valve is completed by means of a rib stem. Because the valve should flip multiple times to travel from receptive closed position, the slow operation conjointly prevents loud noise effects. Gate valves mustn’t be used for regulation or strangulation of flow as a result of

- The rate of flow of the fluid isn’t proportional to the quantity that the valve is opening therefore correct management of fluid flow isn’t attainable.

- Gate and seat could also be subject to excessive wear if the valve is partly open.

Advantages of Gate Valve

- Gate valve provides sensible on/off or shutoff options.

- Pressure drop throughout operation is incredibly less.

- Gate valves square measure bi-directional valves and may offer shut-off in either flow directions.

- They square measure appropriate for prime pressure and temperature application and needed less maintenance.

- Gate valves tend to be slightly cheaper than ball valves of identical size and quality.

Disadvantages of Gate Valve

- It cannot be wont to regulate or throttle the flow.

- A gate valve is slowing operational and can’t be quickly opened or closed. This is often sensible conjointly because it reduces the possibility of pounding.

- It is susceptible to vibration and noise within the partly open state.

- It’s a lot of subject to seat and disk wear