What is Drum Brake? | What is Disc Brake? | Drum Brakes vs Disc Brakes

A. Introduction of Drum Brakes vs Disc Brakes

What is Drum Brake?

What is Drum Brake? | What is Disc Brake? | Drum Brakes vs Disc Brakes: – Drum Brake is a speed braking system in vehicles; in which Inside the drums are brake shoes with brake pads that press against the drums from the inside to provide braking force. Friction is created by forcing the brake linings against the inside surfaces of the drums in this arrangement. Friction converts kinetic energy into heat energy. When opposed to disc brakes, drum rotation helps press the shoes and lining against the drum with more force, providing higher braking force. On the other hand, it is critical to design the components so that the heat generated by the thermal energy is efficiently dispersed into the atmosphere.

What is Disc Brake?

In a disc brake, its rotors rotate with the wheels, and brake pads attached to the brake calipers clamp down on these rotors to halt or slow the wheels. The friction created by the brake pads rubbing against the rotors converts kinetic energy into thermal energy. This thermal energy produces heat, but the heat is effectively distributed because the major components are exposed to the atmosphere. This heat-dissipating feature helps prevent brake fade, which is when the heat affects braking performance. Another benefit of disc brakes is their resistance to fluid fade, which happens when water on them dramatically reduces braking force. The rotor rotates at high rates as the vehicle moves, and this rotational motion discharges the water from the rotors, resulting in a consistent braking force.

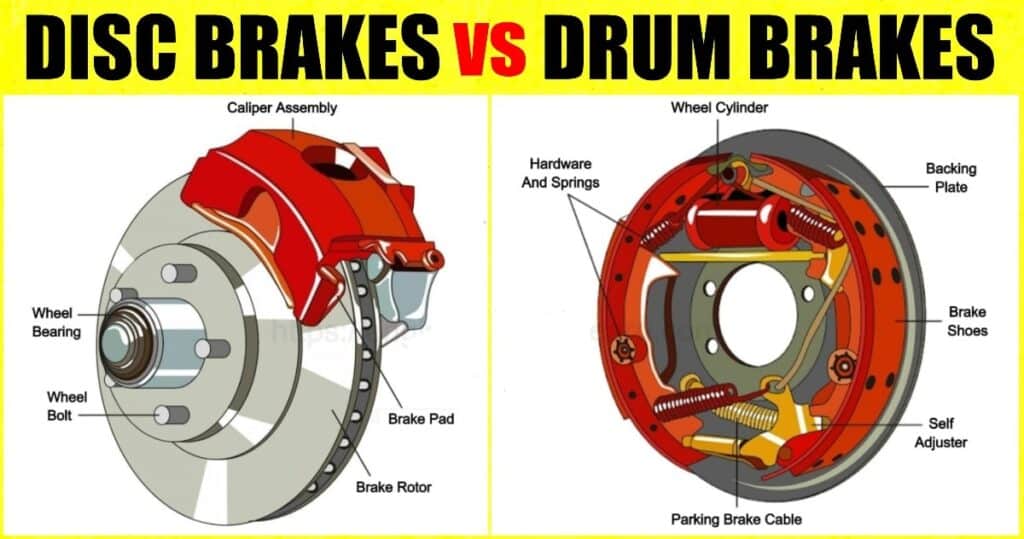

B. Structure of Drum Brakes vs Disc Brakes

Structure of Drum Brakes

Drum brakes are a braking system in which the brake drums revolve along with the wheels. Brake shoes with brake linings are installed within each drum. To generate braking force, pistons press on the drums from the inside, allowing the vehicle to decelerate and stop.

Structure of Disc Brakes

The braking rotor, which spins with the wheel, is gripped on both sides by brake pads fitted to the calliper with pressure from the piston(s), slowing and stopping the vehicle.

C. Working of Drum Brakes vs Disc Brakes

Working of Drum Brake

- When you press the brake pedal, the fluid in the master cylinder is compressed, allowing the piston of the wheel cylinder to extend outward.

- The brake shoe is forced outward against the braking drum by the outward motion of the wheel cylinder piston.

- The wheel’s motion is reduced as the brake shoe lining meets the inner surface of the drum, and the vehicle stops owing to friction between the brake shoe and drum.

- When the brake pedal is depressed, the retraction springs pull the brake shoe inward, and the contact between the friction lining and the drum is broken. The brake is now ready to be applied once more.

- At the bottom, there is a self-adjusting screw that is utilised to keep the space between the drum and the brake shoe as small as possible. When the brake shoe lining wears down, the space between the drum and the brake shoe widens, and the adjuster is repositioned to maintain the minimal gap.

Working of Disc Brake

- When the brake pedal is depressed, the master cylinder’s high-pressure fluid pushes the piston outward.

- The brake pad is pushed against the revolving disc by the piston.

- As the inner brake pad makes contact with the rotor, the fluid pressure increases, and the calliper advances inside, pulling the brake pad towards the rotating disc, where it makes contact.

- Both brake pads are now pushing the rotating disc, and there is a lot of friction between the pads and the moving disc, slowing the vehicle down and finally allowing it to stop.

- The piston travels inward when the brake pad is released, and the brake pad moves away from the rotating disc. The truck then begins to move again.

Components of Drum Brake

1. Backing Plate

The backing plate is a relatively thin metal-based band placed on the back of the drum brake system and is one of the drum brake components. This component protects other drum brake components. The backing plate is shaped like a circle with several holes and protrusions. The primary function of the number of holes in the backing plate is to match the drum brake’s standard part.

2. Wheel Cylinders

Drum brakes are made up of wheel cylinders that transform fluid pressure into mechanical action. In drum braking systems, numerous types of wheel cylinders are commonly encountered or employed. Because it is frequently employed to complement leading and trailing drum types, the dual-piston wheel cylinder is the most popular. Bolts are the best way to describe the twin-piston style of the backing plate. The wheel cylinder comprises various components, including the bleeder nut, piston boot, spring, and piston.

3. Return Spring

The return spring is an important drum brake component that returns the brake shoe to its original position before the brake lever or pedal pressure is applied. The return spring in a drum braking system is made up of two parts: the upper spring and the lower spring.

4. Brake Shoes and Pads

Drum brake components such as brake shoes and pads are also common. A brake shoe or brake pad applies the brake on a drum brake system. The brake pad is where the brake pads are placed in the disc brake components. Brake shoes are shaped like a circle, with two shoes connected by a semicircle. The brake shoe will not touch or directly contact the drum because this component is located in one area of the brake. Brake pads are components that sit directly on the brake shoe’s surface. Brake pads are made of an organic ceramic material that may be changed or replaced as they become thin or worn out.

5. Brake Shoe Holder

The brake shoes will be connected to the backing plate and put or kept. The brake shoe holder is either dynamic or movable. The holding mechanism may then properly support the drum brakes. Several pins, springs or spring locks, and a pressure plate make up the brake shoe holding. When the three components are put together, they establish a crucial connection to the backing plate.

Components of Disc Brake

1. Brake Calipers

Brake callipers, often called callipers, are an important component of disc brakes in automobiles. Callipers will make a mechanical movement to clamp the brake lining on the disc. Brake pads and piston brakes are other terms for callipers. The hydraulic pressure generated by the change in brake fluid pressure that enters through the brake line or cable will be used to operate the brake callipers. You should be familiar with at least two types of brake callipers: floating and fixed.

2. Calliper Bracket

Because the calliper bracket is used to attach the calliper, it cannot be removed from the car disc brake unit because the calliper bracket keeps the calliper in place and prevents it from moving.

3. Disc Plate

Disc plates are disc brake components directly connected to the axle axles and rotate in tandem with the wheels. This disc brake component constitutes a critical component of automobile disc brakes. The brake pads will clamp or press the disc, causing the braking process to appear on the car. Cast iron is the most common material for disc discs.

4. Brake Shoes

Brake shoes are a component of disc brakes that emphasise the disc part to generate friction to stop the disc brake from rotating.

5. Piston Brake

The piston brake, shaped like a tube with a groove, is inside the calliper. The piston brake works by pressing or pushing the brake lining against the disc to slow or halt the wheel spinning.

Conclusion

Brakes are a vital part of every car; we rely on them to stop and assist us in avoiding a collision or accident. The vehicle industry has come a long way from the early days of woodblock brakes to today’s sophisticated drum and disc brakes. The two most prevalent brake systems seen in today’s automobiles are drum and disc brakes, and in many cases, both are used on the same vehicle. We look at the benefits and drawbacks of each system to help you understand the differences.