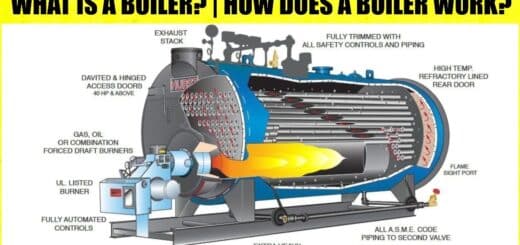

Float Valve: Definition, Function, Control System, Advantages, Problems & Remedial Measures

What is a Float Valve?

Float Valve: Definition, Function, Control System, Advantages, Problems & Remedial Measures :- Float valves are the valve which controls the liquid level. The float in the valve detects the elevation of free surface of liquid and then opens and closes the valve according to the requirement. Huge numbers of float valves are used in domestic water system. Therefore the float valve controls the level of cold water header tank. In toilet cisterns small float valves are used to measure flush water.

For domestic cold water applications float valves are made to suit 22mm and 15mm copper wire. They are designated as high pressure and low pressure for different conditions. Seat area of high pressure valves are smaller and are able of working up to 16 bars while in some areas pressure of water supply can be upto2 bars.

Function of Float Valve

Brass or bronze is used to cast domestic valve. Generally float valves closes as the liquid surface rises, but in case of industries it is reversed. The float valve is mounted above the liquid level on the side of tank for allowing maintenance without emptying the tank. On low cost valves liquid level is maintained by bending ball arm while the float valve which are superior in quality are have bolted connection in arm.

Incoming liquid can be aerated to great extent if outlet of the valve in not piped below the level of liquid and this aeration can cause problem to pumps which are operating close to net positive inlet pressure (NPIP) or net positive suction head (NPSH). Effective NPSH or NPIP value is lowered by the air coming out of solution.

Advantages of Float Valve

Float valves can prevent overflow or overfilling of tanks when liquid needs to divert instead of dumping in drain. Appropriate valve is provided at the tank base with outlet piped through the wall of tank and the valve communicate with the float arrangement provided by links. For overflow control or for filling large float valves are constructed in same manner like poppet style controlled closure non – return valve.

Combination float valve are used for controlling water level in steam condensers. The body of valve is bolted to the condenser wall and all parts are being subjected to condenser vacuum. The combination included two double beat piston valve. Due to flooded condition, condenser loses capacity then it can lead to serious consequences. When the valve shows water level high position then the bottom valve is opened for allowing condensate to drain into hot well.

In a tank or reservoir float valve is mounted on below or above the required water level, and the float pilot is either connected to main valve through command tube or assembled on main valve.

Problems Associated with Float Valve

Surge problem arises when float valves generates waves on surface of liquid and due to these waves float valves modulate and change the rate at which liquid is flowing. Water hammer is induced when modulation occurs near the valve closure and seat and disc can be damaged. Due to surge inlet process system suffers disturbance problems and pressure gauge vibrates and needles fall off. The surface of liquid must be stable to eradicate this problem. Piping the outlet under the surface and diffusion of flow, stilling tubes across the tank can prevent the movement of surface.

Problem can be arising due to mounting of float valve on wall of tank. Sufficient torque is provided by the ball arm to close the valve, and tank wall should resist the torque but the tank made up of thin wall or glass fiber need reinforcement to sustain the loads. When inlet pressure and valve size increases this problem of torque also increases. Inlet pressure and the seat area are used by the approximate torque, and the actual torque is 20 percent more than this value is the actual torque.

Remedial Measures to Counter the Problem

As far as possible the load is spread because the valve results in developing crack to the tank wall, it will lead to serious consequences. Balanced valves or equilibrium float valves are used for solving the problem due to high operating torque, balance valves work in same manner to double beat globe valve. The balanced valves have a balanced piston and a valve, the balanced piston have area same as the area of the valve but it is loaded in opposite direction with the same inlet pressure. A small friction introduce in balance piston can also reduce the operating torque significantly.

Materials and Size

The material used for float valves are stainless steel, cast iron and gunmetal. Nominal pressure (PN) up to PN20 is normal. These valves are available in size DN15 Nominal diameter) to DN300.

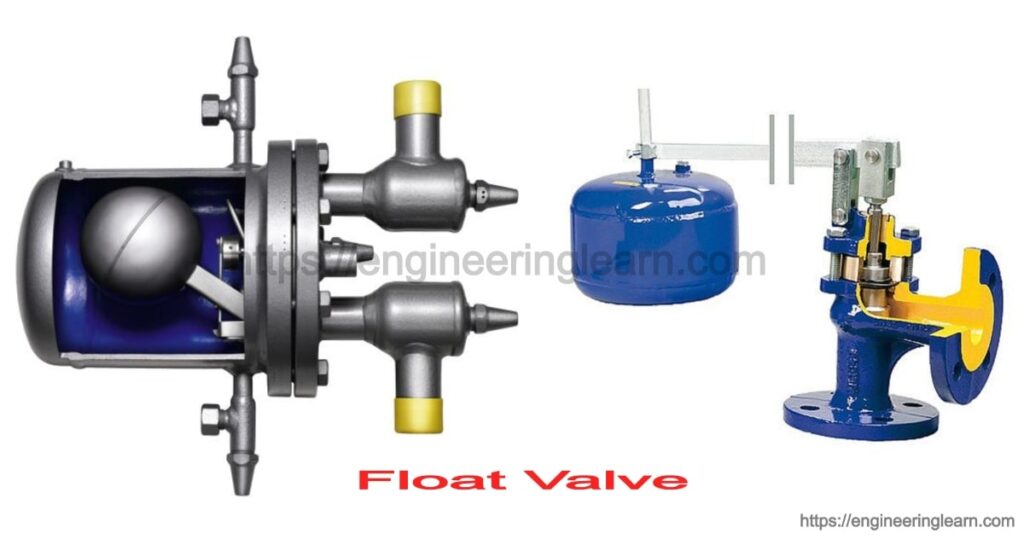

Control System of Float Valves

The control system of the float valve requires float valves as well as float switches.

1. Float Switch

It can be used as control switches or as alarm devices to turning ON or OFF pump or for sending signal to the valve actuator. Float switch have switched output and it can be electromechanical or solid state, normally closed or open. The float switch provides control over motors which pumps liquid into a tank or from a sump but the tank operation is exactly opposite to the sump operation. On the basis of location of float in liquid the float switch is actuated.

2. Float Valve

It is mounted on reservoir or tank inlet, and it can closes when level of water rises by filter discharge pressure which is acting with tension spring on top of diaphragm in valve cover. When float descends due to drop in level of water by filter discharge pressure acting under valve disk, the float valve get open. In general level of water is maintained at the maximum point.

Image Source :- Sciencedirect, Zetkama