Fire Pump: Types of Fire Pumps and How do Fire Pumps Work?

Fire Pump Introduction:

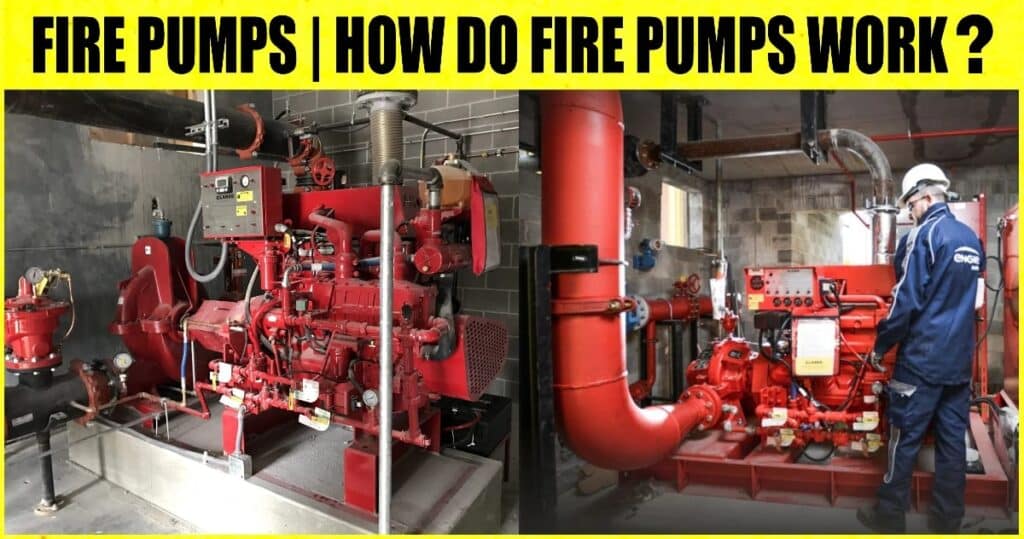

Fire Pump: Types of Fire Pumps and How do Fire Pumps Work? – Fire pumps are critical components of a building’s fire prevention system, particularly in high-rise buildings. Fire pumps are crucial in distributing water through sprinkler systems in buildings with 400-500 feet or higher levels where water pressure from water mains and firefighting equipment cannot reach. Even in low-rise structures, a fire pump is essential for fire suppression.

Firefighting is a dangerous job at best, but without a well-designed and properly installed system and pump, it becomes more deadly, putting corporate assets and lives at risk.

When hydraulic calculations show that the present water supply cannot deliver enough pressure to fulfil the hydraulic design requirements of the suppression system, fire pumps are used. This is common in tall buildings (to compensate for hydraulic head losses caused by elevation differences), systems that require a relatively high terminal pressure at the fire suppression outlets (to allow sufficient water droplet penetration of a fire plume), or systems that require a large discharge of water (such as storage warehouses). Fire pumps are also required if a stationary source supplies the fire protection water with little or no pressure. These factors may exacerbate some situations, necessitating large amounts of water and powerful fire pumps.

How do Fire Pump Work?

A fire pump is an essential component of a fire sprinkler system because it allows high-pressure water to enter the system, boosting the flow rate of the water. To understand how a fire pump works, first define what a fire pump is. A fire pump is more than the name implies a pump an essential component of the system; the entire system comprises the motor or driver and the controller.

A fire pump, part of a fire sprinkler system, gets water from an underground water source, a water tank, lake, or reservoir and is driven by electricity or diesel fuel. The high-pressure pump delivers water through the sprinkler system and hose standpipes. The most common fire pumps are the horizontal split case, vertical in-line, and vertical turbine.

Types of Fire Pumps

1. Horizontal Split Case

The most frequent style of a fire pump is a horizontal split case. Although it requires a water supply that is not part of the system, it is nonetheless simple. This implies that many fire protection suppliers choose it over its competitors. The horizontal split case system’s components are simple to access and maintain. The individual component sizes also vary, making it easy to replace them over time as the system requires. These systems are built to survive for years and ensure a consistent water supply.

2. Vertical in-Line

Split-case fire pumps are smaller than vertical in-line fire pumps. These conserve space and are perfect for tiny enterprises or other facilities with limited space. Although these devices do not require a particular foundation to be anchored, issues occur regarding preventative maintenance. This is because the complete fire pump system must be dismantled and removed.

3. Vertical Split Case

Similar to horizontal split case fire pumps are vertical split case fire pumps. The difference is that they take up considerably less floor area because they are vertical. This can be a significant differential, particularly in small firms with little room for essential fire protection measures. One significant advantage of this fire pump is that its design protects the motor from floods.

4. Vertical Turbine

Whatever other systems are built, they always require positive suction to pull water from its source. Vertical turbine fire pumps are exempt from this requirement. The vertical turbine fire pump, on the other hand, may pull water from neighbouring wells or tanks. Water is pushed to the top and then supplied as needed.

5. Jockey Pump

A jockey pump, also known as a pressure-maintenance pump, is a tiny device that operates in tandem with a fire pump as part of a sprinkler system. It is intended to retain the pressure in the system at a certain level when it is not in use so that the fire pump does not have to operate constantly and the system does not go off randomly. It can also assist protect the system when fire and water surge into the pipes.

Fire Pump Installation and Maintenance

Installation and maintenance of any fire system, including the choice of pump and system, should be done by fire safety specialists. According to the National Fire Protection Association (NFPA) and the International Building Code (IBC), revised regularly, several issues exist.

Though trained personnel on-site can perform weekly inspections, monthly, annual, and additional inspections and maintenance should be performed by qualified personnel, such as factory-trained and certified personnel, personnel certified by a nationally recognised fire protection organisation, or personnel registered, licensed, or certified by a state or local authority.

Choosing the Correct Pump Driver

- Electric motor-driven and diesel engine-driven fire pumps are the most often used.

- Wherever feasible, electric-driven pumps are preferred since electric motors are more compact and require fewer mechanical parts, making them more cost-effective.

- Electric-powered pumps can be powered by a utility connection, a generator, or another approved power source by your AHJ.

- Diesel-powered pumps are commonly employed when the power grid is unstable or incapable of handling the load of an electric-powered pump. They are also employed in situations with a shortage of emergency power, such as a generator.

- Diesel-powered pumps are subject to stricter rules than electric pumps because of the additional processes required to handle the fuel system, cooling, exhaust, vibration, and so on.

- Diesel-powered pumps, for example, need additional space for fuel tank storage and must be housed in a separate enclosure or chamber with direct access to the outside.

How are Fire Pump Sized?

Typically, the size of the fire pump required is decided during the design of a sprinkler system. A hazard study must be performed initially when constructing a sprinkler system to identify the occupancy categories, which are set based on the estimated fire dangers in different places inside the structure. This analysis determines the number of sprinkler heads necessary. Furthermore, while the number of sprinkler heads supplied is a significant consideration for designing a fire pump, the size necessary is based on the most hydraulically demanding location of the total sprinkler system, which may or may not be the area with the most sprinkler heads.

- Distance – The structure’s footprint determines how far water must travel laterally to reach the furthest sprinklers.

- Elevation – The designer must consider the number of levels in the structure. Because of gravity’s effects, greater pressure will be necessary to send water to sprinklers on higher floors.

- Occupancy Classification – It is critical to understand whether and where there are risks within the structure that may necessitate more water to extinguish a fire. A danger study must be performed before sizing the fire pump.

Because numbers stated in GPM cannot be easily translated into PSI, correctly sizing the fire pump becomes much more complicated. Thus, while sprinkler system capacity is defined in terms of gallons per minute (GPM) the amount of water flowing through the system fire pumps are typically sized by pressure range, pounds per square inch (PSI).

Content Source: – firefighter, impactfireservices, firesafetysecurityindia, csemag

Image Source: – valleyfire