Woodruff Key: Definition, Types, Uses, Sizes, Operation, Material, Working, Applications, Advantages & Disadvantages

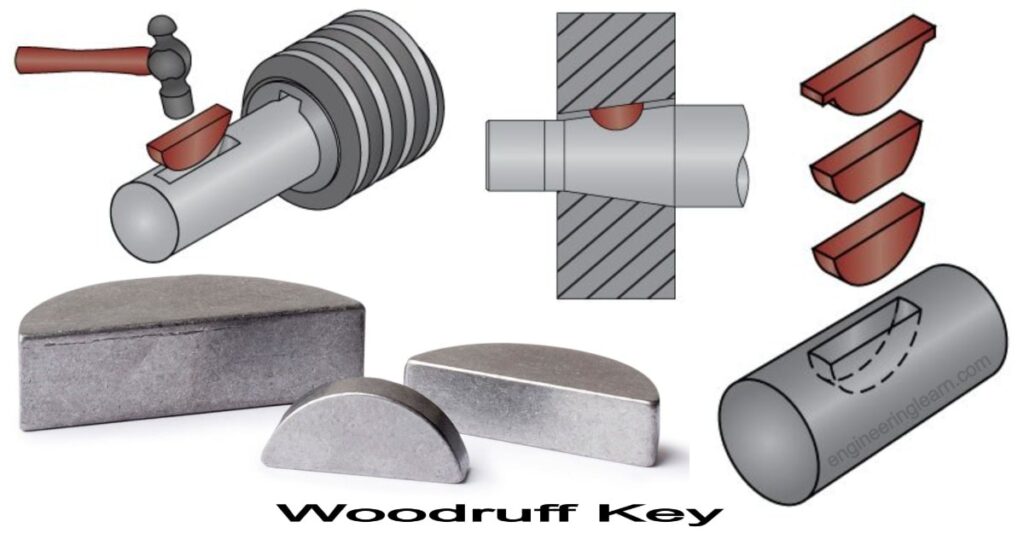

Woodruff Keys: Definition, Types, Uses, Sizes, Operation, Material, Working, Applications, Advantages & Disadvantages :- Woodruff can be defined as a semi circular of half moon shaped, partly fitting in a circular segment keyway and remainder in the longitudinal slot of the keyway (woodruff keyway are semi circular pocket which is drawn in shaft for the placement of woodruff key) in mating part. With the help of plunge cutting with woodruff cutter the circular segment can be directly cut.

The advantage of using the woodruff key is the removal of milling around the shaft shoulders where concentricity and stress concentration can be affected, which is very important for operating in high speed. The suitable fitting of the keyway and key also helps in increasing the reliability of key.

Description of Woodruff Keys

Woodruff keys are of semi circular disc shaped which completely fits into the circular recess provided in the shaft and then the shaft was machined with woodruff keyway cutter. The woodruff keys are generally used in automobile shafts and machine tools from 6 mm to 60 mm diameter. Due to extra depth provided to the woodruff key it can be easily fit into the mating part and after that no gap left in between those parts. They can be easily used and are very adjustable in comparison to the various keys.

Operation of Woodruff Key

The woodruff keys are inserted to the curved slot of the shaft and then properly installed and get captive there and does not walk out of shaft but are difficult in installing. The key is pushed down in the curved groove of the milled in shaft and are arranged in line therefore its flat top will be side by side with shaft.

Installation of the Woodruff Key

- In the process of installation of woodruff key first of all it is pressed in the key way or pocket provided in the shaft manually.

- When the woodruff key is fitted into the shaft, then alignment if the flat surface of the woodruff key is done with the slot provided in the hub.

- For getting proper assembly, the shaft or hub are moved with key in each other.

- Tapping is provided lightly with the hammer and then we have shaft assembly and coupling.

Applications of Woodruff Key

Woodruff keys are generally used for application which are light duty and for mounting taper bored components on the end of tapered shaft.

- Machine tools,

- Automotive applications

- Snow blowers

- Marine propellers.

Working of Woodruff Keys

For placing the woodruff key at place at the time of installing mating component, it is to be ensured that it is tightly situated in key seat. As the woodruff keys are made up of high tolerances, they need to be press for fitting in its seat which can be done by just slightly tapping the flat face of the woodruff key with the help of a hammer till they seated firmly. If the key slips out or falls at the time of installation it means that the key is small for host groove. When they are placed once they help in preventing hubs, gears and various components to move independently of the spindle or the rotating shaft.

Uses of Woodruff Keys

- They are generally used in machine tools like in between the crankshaft and the flywheel of internal combustion engine.

- Woodruff key are used for pulleys to shafts and locking gears, they fit into key seat on the shaft which retain the key and are circular pocket and the key fit portion which is exposed fits in a rectangular groove which is known as keyway in the pulley or the gear.

- They are used for eliminating milling around shaft shoulder.

- Woodruff key generally provide good fixing area to the shaft because the flat top surface engage with the gear or hub and thus have better fixing.

Types of Woodruff Keys

Following are the types of woodruff keys:

1. Full Radius: ( Types of Woodruff Keys )

In shape it is full half circular and are in with shaft’s seat. This type of woodruff key requires high precision as well as tight fit tolerance because even a very small deviation from the size does not make assembly with hub.

2. Flat Bottom: ( Types of Woodruff Keys )

Flat bottoms are of same shape as the standard key but the bottom is flat. Therefore they can easily adjust in the groove.

3. High Pro Key: ( Types of Woodruff Keys )

High pro key have small difference in the profile at the top. Step is at flat part on to for having support at the time of assembly.

Material Used for Woodruff Keys

Woodruff key are made up of carbon, stainless steel and alloy. Alloy steel and carbon are durable but they need to be coated or plated for preventing it from corrosion. Stainless steel is corrosion resistance but they are less strong as compared to the carbon woodruff key.

- Carbon steel and alloy steel are provided with plain finish.

- Carbon steel areprovided with zinc plated.

- Stainless steel are passivated with oxidation process.

Advantages of Woodruff Keys

- Woodruff key is a easily adjustable key.

- Woodruff key is essential for operating high speed.

- Woodruff key are able in accommodating taper in hub keyway.

- They are adjustable and can tilt in key seat or keyway.

- Woodruff key exact fit of keyway and key which results in increasing the reliability of the key.

- They are useful for shaft end. Their extra depth in shaft reduces the overturning tendency in its keyway.

- Woodruff eliminates the milling around the shaft shoulder where concentricity and stress concentration can be affected.

Disadvantages of Woodruff Keys

- They cannot carry high load.

- They can’t be used as feather.

- The shaft get weakens with the depth of the keyway.

- Woodruff keys are difficult in installing and are short.

- They are not used for the transmission of heavy torque like multi groove V belt pulleys, it is expensive to carry heavy load create problem in installation process.

Image Source :- keysandpins, huyett