Poppet Valve: Types, Working, Operation, Diagram, Applications, Advantages & Disadvantages

What is a Poppet Valve?

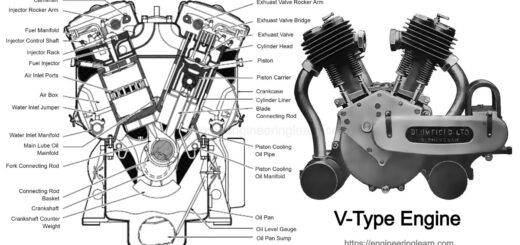

Poppet Valve: Types, Working, Operation, Diagram, Uses, Applications, Advantages & Disadvantages :- The poppet valve, also known as mushroom valve, is generally used in an internal combustion engine to control the flow of combustible fuel into the engine and burnt fuel out of the engine. It is discovered by E.A.G. Young, an American engineer, in 1833. The “poppet” comes from the English word puppet which means a doll which can be controlled from the above using wires or strings or by any other means. Similarly the poppet valves are also controlled by a cam and gear assembly powered by the engine shaft.

Working Principle of Poppet Valve

Poppet valves are used in most of the reciprocating internal combustion engines to open and close the exhaust and intake manifold of the engine cylinder. As, the cam rotates and pushes the valve upward against the spring, the poppet head lifted from its seat and the space for gas flow is generated. The more the cam lifts the valve, more will be the port opening and more volume of gas will flow into or out of the combustion chamber. Further rotation of the cam, makes the valve to descend downwards by the action of spring force and closes the port.

Operation of Poppet Valve

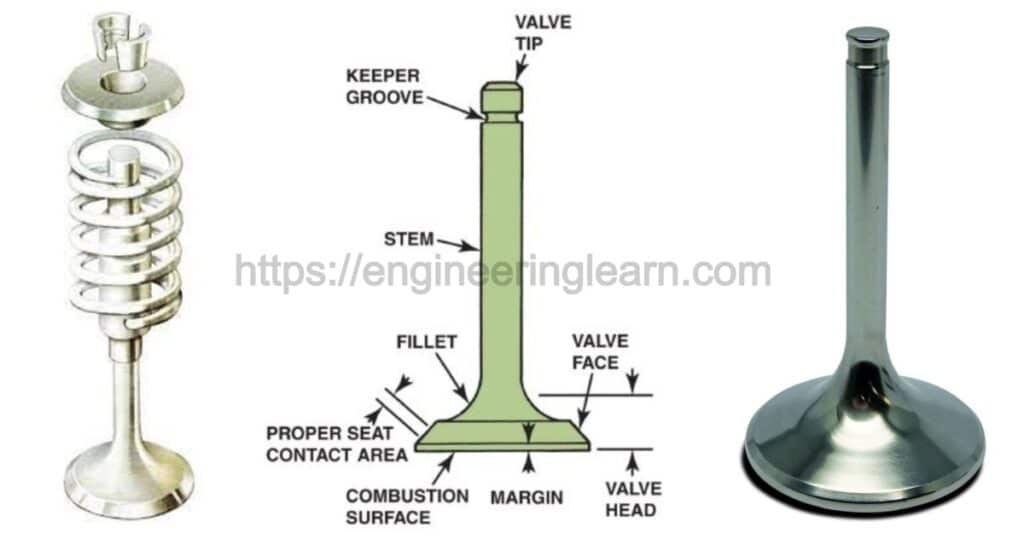

To avoid the corrosion and thermal fatigue, the body of the poppet is made of stainless steel. The seat face of the poppet is grounded to an angle of 45o so that it can cover the port completely and hence leak proof covering of the port is possible. The poppet valve generally consists of a round stem tip, called head, of mushroom shape, used to shut away the passage by pushing the head on to the valve seat by the combined action of fluid pressure and spring force. The valve can be operated manually, by cam action, electrically, by solenoid, or pneumatically.

Types of Poppet Valves

There are two types of poppet valves mainly utilized for the required purpose; Two way normally closed valve and two way normally opened valve. In the former one, the stem of the valve pushes the head away of its seating to open the passage for fluid flow. These valves remain closed in normal condition. The former one remains open in normal condition. The stem of the valve pulls the head towards its seating and closes the passage for fluid flow.

Manufacturing of Poppet Valve

To avoid the corrosion and thermal fatigue, the body of the poppet is made of stainless steel. The seat face of the poppet is grounded to an angle of 45o so that it can cover the port completely and hence leak proof covering of the port is possible. The poppet valve generally consists of a round stem tip, called head, of mushroom shape, used to shut away the passage by pushing the head on to the valve seat by the combined action of fluid pressure and spring force. The valve can be operated manually, by cam action, electrically, by solenoid, or pneumatically.

Application of Poppet Valve

The poppet valve does not require lubrication, which is the plus point to select the poppet valve without worrying about the chemical compatibility of the lubricant with various fluid applications. This also makes them eligible for the application for any system in which clean, dry air is needed, i.e.; medical application. The poppet valves generally have self-cleaning tendency as the large relative valve opening produces a large flow through it, sweeping away contaminates resides over the surface of the valve. The poppet valves are commonly employed for pressure holding and pressure release in the single-acting cylinder engines. They are also used in loading unloading in case of positive displacement pumps. Sometimes, the poppet valves are serving as relief valves in air tanks.

Advantages and Disadvantages of Poppet Valves

Poppet valves offer several advantages over other flow control valves. The advantages mainly includes higher flow rate, closed crossovers, fast response time, long term life cycle due to low friction, low contaminant damage due to its shape and lower cost. The crossover means to a time period in which one valve opens slightly before another is fully closed. This gives an importance to the poppet valve when precise control is needed over the flow of fluid.

The response time is quicker with poppet valve because of the shorter movement is required to induce the high flow rate in to the engine cylinder but the response is not consistent as the opening and closing of valve also depends upon the gas pressure of the engine. Moreover, the poppet valve also cannot be used in the vacuum application. The poppet valves generally used with the springs but when it is used as check valves, it may or may not used with springs, depending upon the valve design and requirement. But, when it is used as relief valve, it definitely incorporated with springs.