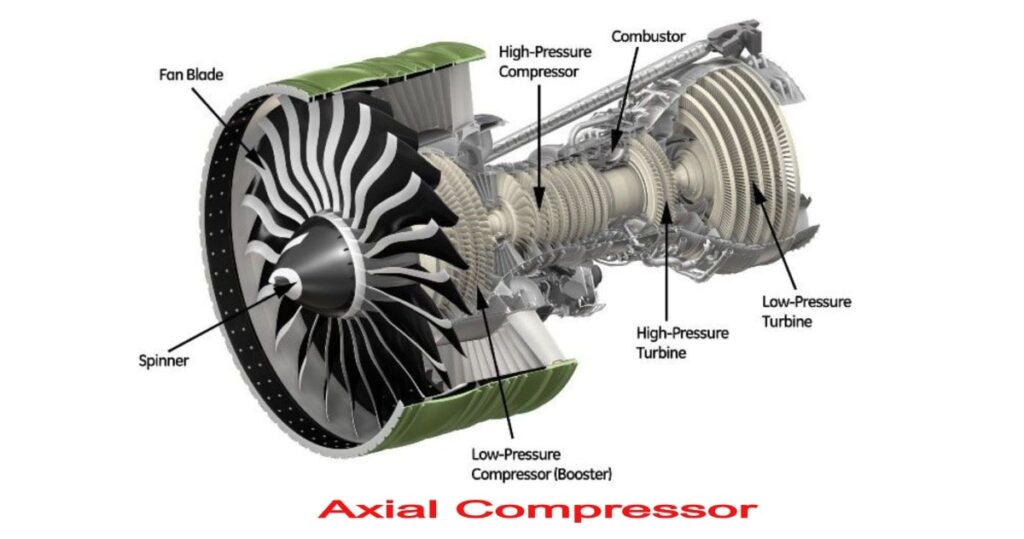

7 Types of Air Compressor: Definition, Uses & Working Principle [Explained in Detail]

Introduction of Air Compressor

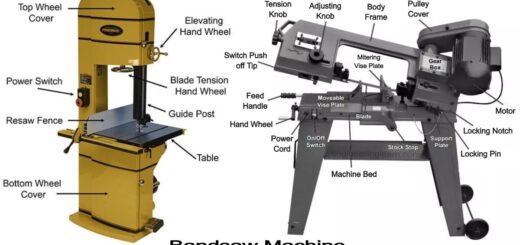

Air Compressor Types and Working Principle :- Air compressors are referred to as some of the most necessary appliances which are found mostly at the construction sites, as they are found using the power source for the electric tools. There are numerous types of air compressors, each one having its own unique capabilities as well as drawbacks. Therefore, the air compressors are mainly categorized as either positive displacement or dynamic displacement, which is based on their internal mechanism.

Types of Air Compressor

The Four most common types of air compressors which are commonly known are as follows:

- Rotary Screw Compressor

- Reciprocating Air Compressor

- Axial Compressor

- Centrifugal Compressor

- Positive Displacement Compressor

- Dynamic Compressor

- Isentropic Compressor

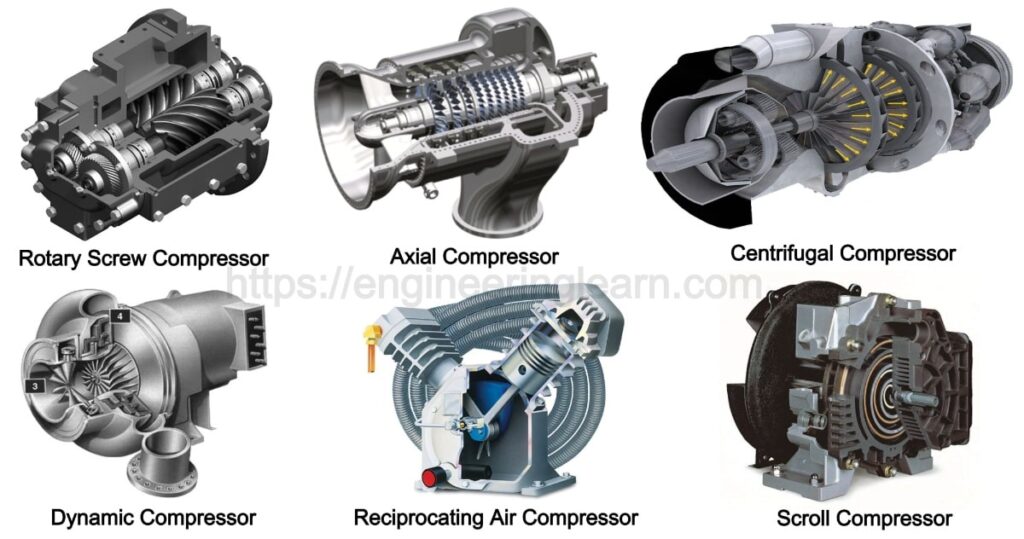

1. Rotary Screw Compressor: ( Types of Air Compressor )

Rotary screw compressors are referred to as those compressors which are a common type of displacement compressor. These are some of the easiest types of air compressors in terms of taking its care, as these are the machines which are equipped with an internal cooling system and does not require high maintenance. These compressors are found to be typically large as well as industrial-sized machines which can either be lubricated with oil or can even run oil-free.

These are the compressors which generate energy via two internal rotors which gets turned in the opposite direction. The air which gets trapped within the two opposing rotors, is responsible for building up pressure within the housing. Due to the internal cooling system, these are the air compressors which are designed for continuous use and also range in power from 5 horsepower to 350 horsepower.

Operation

Rotary screw air compressors are found quite easy to maintain and operate. The capacity control of such compressors is accomplished by the varying speed as well as the varying compressor displacement. There is also found a slide valve which is located inside the casing. As soon as the capacity of the compressor is reduced, the slide valve gets opened by passing a required portion of the compressed air back to the suction.

Advantages

There are various advantages of using a rotary screw compressor which includes smooth, pulse-free air output in a compact size along with a high output volume over a long life. The rotary screw air compressors which are found to be oil free, utilizes the specially designed air ends in order to compress the air without the presence of oil in the compression chamber in order to yield true oil free air. Oil free rotary screw air compressors are the ones which are air cooled and water cooled and also provides the same flexibility as that of an oil flooded rotaries whenever the oil free air is required.

2. Reciprocating Air Compressor: ( Types of Air Compressor )

Reciprocating compressor is referred to as another popular type of displacement compressor which is typically found at the smaller work sites like the garages and home construction projects. The reciprocating compressor is not similar to that of a rotary screw compressor as it is not designed for the regular use. A reciprocating air compressor is found having more moving parts as compared to a rotary screw compressor wherein these parts are lubricated with oil for smoother movement.

These are the types of air compressors which work via piston which is present inside a cylinder, which also compresses and displaces the air in order to build the pressure. Reciprocating compressors can also come in single or multi-stage variations, which can directly or indirectly affect the pressure ranges which can be achieved.

Single-stage and two-stage reciprocating compressors are specifically the machines which are used commercially. Single-stage compressors are generally used for pressures varying in the range of 70 psig to 100 psig.

The two-stage compressors are usually used at places wherever higher range of pressure is required. This can range from 100 psig to 250 psig.

The unit consumption in a reciprocating compressor is usually 1 HP ~ 4 CFM at 100 psi and that 1 to 50 HP. Compressors which are found to be 100 HP or above are typically Rotary Screw compressors or Centrifugal Compressors. Whenever there is a need of more power, the multi-stage compressor will be used. Whereas the single-stage compressors are the ones which can get the job done for smaller projects like woodworking and metalworking and multi-stage compressors are used to provide the power which is needed for intense construction like auto assembly and maintenance. Multi-stage reciprocating compressors are found to reach up to 30 horsepower.

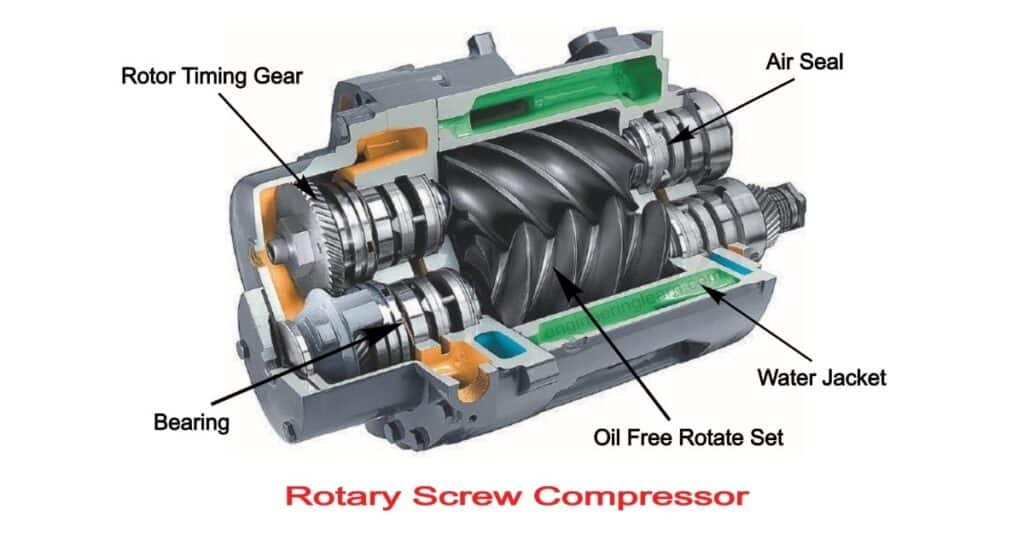

3. Axial Compressor: ( Types of Air Compressor )

Axial air compressors are referred to as those compressors which are not typically used in the construction projects whereas are found in higher-speed engines on ships or planes. These are the compressors which are found having higher-efficiency rate but are highly expensive as compared to the other types of air compressors, and can get up to thousands of horsepower due to which they are mainly reserved for the aerospace research.

4. Centrifugal Compressor: ( Types of Air Compressor )

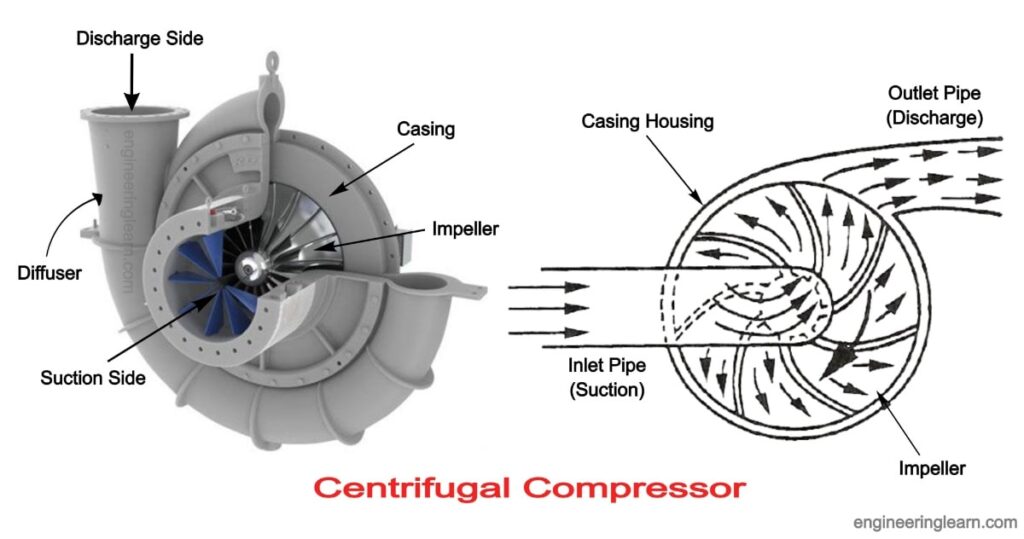

Centrifugal air compressors are referred to as those compressors which slow and cool the incoming air through a diffuser in order to build up the potential energy. Due to the presence of multi-phase compression process, the centrifugal compressors are the ones which are able to produce high amount of energy in a relatively small machine. These compressors are the ones which require less maintenance as compared to the rotary screw or reciprocating compressors and some types can even produce oil-free air. These are the compressors which are typically used for more demanding construction sites like the chemical plants or steel manufacturing centres, as they can reach up to 1,000 horsepower.

Adjusting the inlet guide vanes is a very popular method in order to control the capacity of a centrifugal compressor. By closing the guide vanes the volumetric flow along with the capacity gets reduced. The centrifugal air compressor is referred to as an oil free compressor in terms of design wherein the oil lubricated running gear is separated from the air by the shaft seals along with the atmospheric vents

5. Positive Displacement Compressor: ( Types of Air Compressor )

Positive displacement compressors are referred to as those compressors which encompass a variety of different air compressors which is responsible for generating power via air displacement. Air compressors in this category work are quite different from the internal mechanisms, as the principle for each of them is quite same. A cavity which is inside the machine stores the air which is brought from outside, and then slowly compresses the cavity in order to increase the air pressure as well as the potential energy.

6. Dynamic Compressor: ( Types of Air Compressor )

Dynamic air compressors are referred to as those compressors which are found generating horsepower by bringing the air with rapidly rotating blades and then restricting the air in order to create pressure. After this the kinetic energy is stored as static within the compressor.

7. Isentropic Compressor: ( Types of Air Compressor )

An isentropic compressor is referred to as those compressors which can be idealized as either internally reversible or adiabatic. Therefore, an isentropic steady state device is referred to as the change in entropy which defines the compression cycle as isentropic. There can be an ideal efficiency for the process which can be attained along with the performance of an ideal compressor which can be compared to the actual performance of the machine. Isotropic Compression is mainly used in ASME PTC 10 Code which refers to as a reversible adiabatic compression process.

Selection of Most Appropriate Air Compressor

Other than the power-generating mechanism and the energy output levels which are already discussed above, there are various other factors which need to be considered while selecting the right types of air compressors.

1. The Quality of Air from Oil Free Compressors

In order to clean the manufacturing environments, the use of oil-powered air compressors are the ones which can create problem. Mostly the air compressors rely on oil in order to lubricate the inside mechanism along with the fumes which can contaminate the air and result in damaging the products or manufacturing processes. Whereas by using an oil-free air compressor, this risk can be highly reduced.

Although oil-free compressors are the ones which are generally quite expensive and they are the only option for facilities which guarantee the clean manufacturing. There can still be requirement of oil in order to lubricate the machine however, the inner workings of oil-free compressors are found containing a different sealing mechanism in order to ensure that no oil gets entered into the actual compressor. Other than the clean air, oil-free compressors are the ones which often have lower running costs as the parts do not need to be changed frequently which even reduces its maintenance cost.

2. Energy Efficiency

If in case you ought to work on any longer construction project, then getting the most energy-efficient air compressor can be worth the extra cost in the long run. Knowing more about energy efficient engines is very important as we all are in a need to protect the precious resources. So, here are some of the important types of air compressors that are found to be quite energy-efficient.

3. Fixed Speed Compressor or Variable Speed Compressor?

Variable Speed-Driven (VSD) compressors are referred to as the ones which are found to save energy and money by either increasing or decreasing the output on demand. If taking about its comparison, the motors are found having a fixed-speed compressors which constantly churns at the same rate. This is ok as the compressor is operational, whereas the unit slows down and the motor continues to run until the machine comes to stop completely. Whole energy is wasted during this cool-down process as the compressor still keeps on running, but no power is being generated.

4. Natural Gas Air Compressor

In various industrial settings, a natural gas compressor is found working well to power tools and equipment. Here are some of examples which include the chemical processing plants, petroleum refineries and manufacturing facilities. These are the units which are found running on natural gas rather than diesel or electricity. Natural gas air compressors are mostly operated with higher efficiently as compared to the other options, even at the partial loads. These are the compressors which are found having better heat recovery capabilities as compared to the electric compressors. In case the efficiency and energy savings are one amongst your main goals then a natural gas unit may be a far better option.

5. Portability Limitations

If you are the once who transport the air compressor between various sites then a portable unit is a good option. These are small, lightweight units which can still deliver energy, but in a compact package. Although these units are not found to be that powerful as compared to the larger units, but the portable compressors can be ideal for smaller construction projects. Certain units can even be plugged into a car’s power adapter in order to fuel an airbrush painting tool or tire inflation tool. So, you must look into the actual requirement and if portability if possible, then selecting a portable unit can be the best option.

6. Need for Additional Features

There are endless add-ons and additional features present in the units, which are available in today’s time whereas it must be analysed that is there requirement for such additional features or not, then only units with such advanced features should be taken. For instance, multiple couplers or air hose splitters are the ones which allow you to hook up multiple tools to your air compressor, so there is no need for you to connect or disconnect whenever you are changing the tasks constantly. There are air compressors with thermal protection add-ons which keeps a track of internal heating and prevents the motor damage in case the machine is overloaded.

Some air compressors are found having belt-drive systems instead of direct-drives, which allows the quieter operation. In case you think that you will need any of these additional features, then make sure that the types of air compressors you choose is compatible to these tools. Otherwise there can be issues while repairing or maintaining the unit. Therefore, a wise decision is mandatory in order to select the best compressor unit according to the site requirement which can save energy, resources, money etc.

Image Source :- airbestpractices, man-es, weebly, sciencedirect, superarbor, pneumatictips